Sourcing Solenoid Valves demands a meticulous approach. Informed decisions ensure optimal performance, reliability, and cost-effectiveness for any system. This comprehensive checklist empowers buyers. It guides them to select the precise solenoid-valve for their specific application requirements.

Key Takeaways

- Understand your application needs. Match the solenoid valve to the fluid type, pressure, and temperature. This ensures the valve works correctly and lasts a long time.

- Choose the right valve type and materials. Decide between 2-way, 3-way, or 4-way valves. Pick materials for the valve body and seals that work with your fluid. This prevents leaks and damage.

- Check electrical needs and environmental factors. Make sure the valve’s voltage matches your system. Consider how heat, moisture, and vibrations might affect the valve. This helps the valve operate safely and reliably.

1. Understanding Application Requirements for Solenoid Valves

Selecting the correct solenoid valve begins with a thorough understanding of the application’s specific needs. This foundational step ensures optimal performance and longevity.

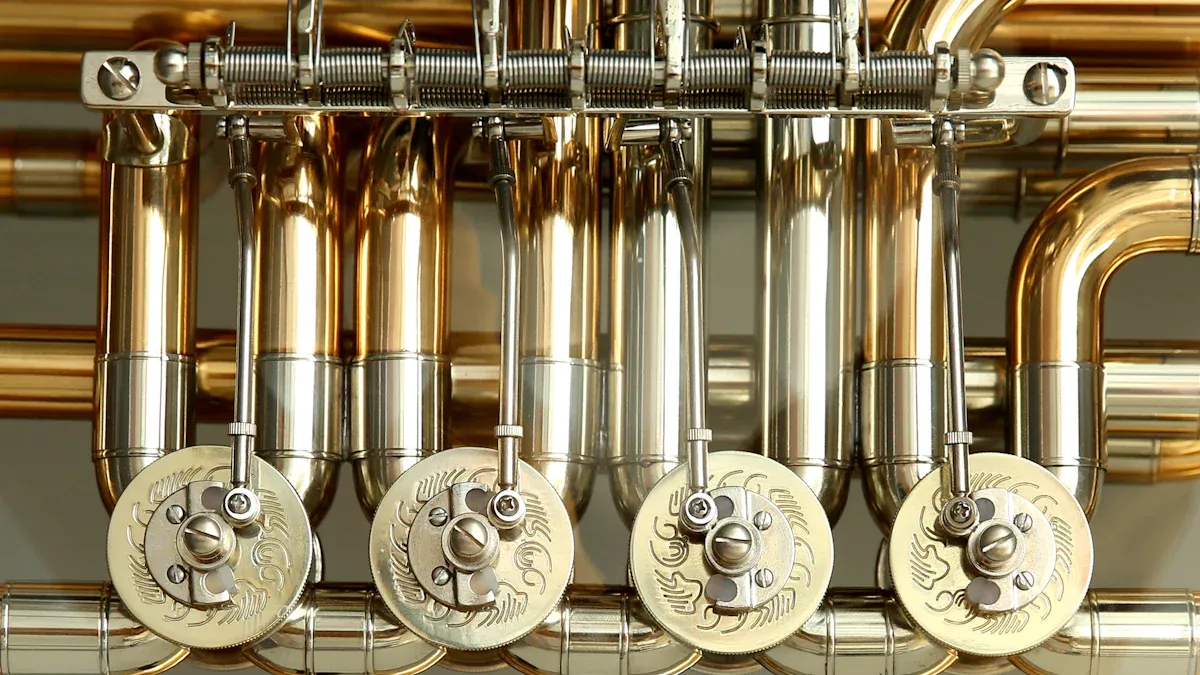

Fluid Type and Compatibility

The type of fluid the valve handles dictates material selection. Common fluids include water, air, oil, steam, gas, and aggressive chemicals. Each fluid possesses unique properties like viscosity, corrosiveness, and temperature sensitivity. For instance, clean water or air often works well with brass or stainless steel bodies and NBR or EPDM seals. Aggressive chemicals or acids require PTFE seals and corrosion-resistant housings, such as PVC or stainless steel. Steam or high-temperature gases perform best with Viton (FKM) seals due to their thermal stability. Media-isolated solenoid valves prevent contamination when handling aggressive acids, slurries, or sensitive biological fluids.

Pressure Range Considerations

Engineers must match the valve’s pressure rating to the system’s operating pressure. This includes both the maximum operating pressure differential (MOPD) and any minimum pressure differential required for valve operation. Incorrect pressure matching leads to valve failure or inefficient system performance.

Temperature Range (Fluid and Ambient)

Both the fluid temperature and the ambient temperature surrounding the valve affect its operation. Standard temperature ranges for solenoid valve operation vary widely. Low-temperature applications, such as cryogenic conditions, operate as low as -50°C. A standard range, typically 0°C to 80°C, suits most general industrial uses. High-temperature systems, like steam, require valves that withstand up to 180°C or more. Miniature solenoid valves generally operate within an ambient range of -20 to 70 degrees Celsius in non-condensing conditions.

Flow Rate and Orifice Size

The required flow rate directly influences the solenoid valve’s orifice size. A larger orifice diameter significantly increases the flow potential. Small orifices create high restriction, lower flow, and a greater pressure drop. Conversely, large orifices result in lower restriction, higher flow, and a smaller pressure drop. For liquids, a larger orifice generally yields more flow per psi of pressure drop. Viscous liquids may require larger orifices than water to achieve the same flow. For gases, orifice sizing considers upstream and downstream pressures, along with flow conditions.

2. Matching Valve Type and Operation When Sourcing Solenoid Valves

Selecting the correct valve type and operational mode is crucial when Sourcing Solenoid Valves. This decision impacts system efficiency and control.

2-way, 3-way, or 4-way Valve Selection

The number of ports defines a valve’s way. A 2-way valve has one inlet and one outlet. It controls basic fluid flow, acting as an on/off switch. They find use in:

- On/Off Applications: These valves provide basic control, starting and stopping fluid flow.

- Temperature Regulation: They adjust fluid parameters to maintain desired temperatures.

- Flow Control: They manage fluid travel between two ports, allowing or blocking flow.

A 3-way valve has three ports. It can switch flow between two outlets or combine two inlets. They are useful for:

- Fluid Mixing: These valves combine fluids from two inlets to a single outlet.

- Diverting Flow: They direct fluid from one inlet to multiple outlets.

- Heating and Cooling: Manufacturers use them to mix and divert media.

A 4-way valve typically has four ports. It directs pressure to one port of an actuator while exhausting another. This is common in double-acting cylinder control.

Normally Open (NO) vs. Normally Closed (NC) Functionality

Solenoid valves operate as either normally open (NO) or normally closed (NC). A normally closed valve remains shut when de-energized. It opens when the coil receives power. Conversely, a normally open valve stays open without power. It closes when energized. The choice depends on system safety requirements and the desired default state during power failure.

Direct Acting vs. Pilot Operated Mechanisms

The actuation mechanism significantly affects valve performance.

| Feature | Direct-Acting Solenoid Valves | Pilot-Operated Solenoid Valves |

|---|---|---|

| Response Time | Rapid response times. | Slower response times. |

| Energy Use | Consume more energy. | Consume less energy. |

| Flow Rates | Manage lower flow rates. | Can handle larger flow rates. |

| Pressure | Suitable for low and high-pressure environments. | Requires a minimum pressure differential. |

| Mechanism | Solenoid coil directly moves the plunger. | A pilot valve controls the main valve. |

Direct-acting valves use the solenoid coil to directly move the plunger. This provides rapid response times. They manage lower flow rates. They are suitable for low and high-pressure environments. Their main orifice size must be smaller.

Pilot-operated valves use a small pilot valve to control the main valve. They leverage line pressure for actuation. This allows them to handle larger flow rates. They consume less energy. However, they require a minimum pressure differential for operation. This mechanism allows for a larger orifice, accommodating greater pipe sizes.

3. Material Compatibility for Durability and Longevity

Material selection directly impacts a solenoid valve’s durability and longevity. Engineers must choose materials compatible with the fluid, operating conditions, and environment. This prevents premature wear, corrosion, and failure.

Body Material Choices

The valve body material forms the primary housing. Common choices include brass, stainless steel, and various plastics. Brass offers good strength and corrosion resistance for general-purpose applications like water or air. Stainless steel, particularly 316L, provides superior corrosion resistance for aggressive chemicals, high temperatures, and food-grade applications. Plastic bodies, such as PVC or PVDF, suit highly corrosive media at lower pressures and temperatures.

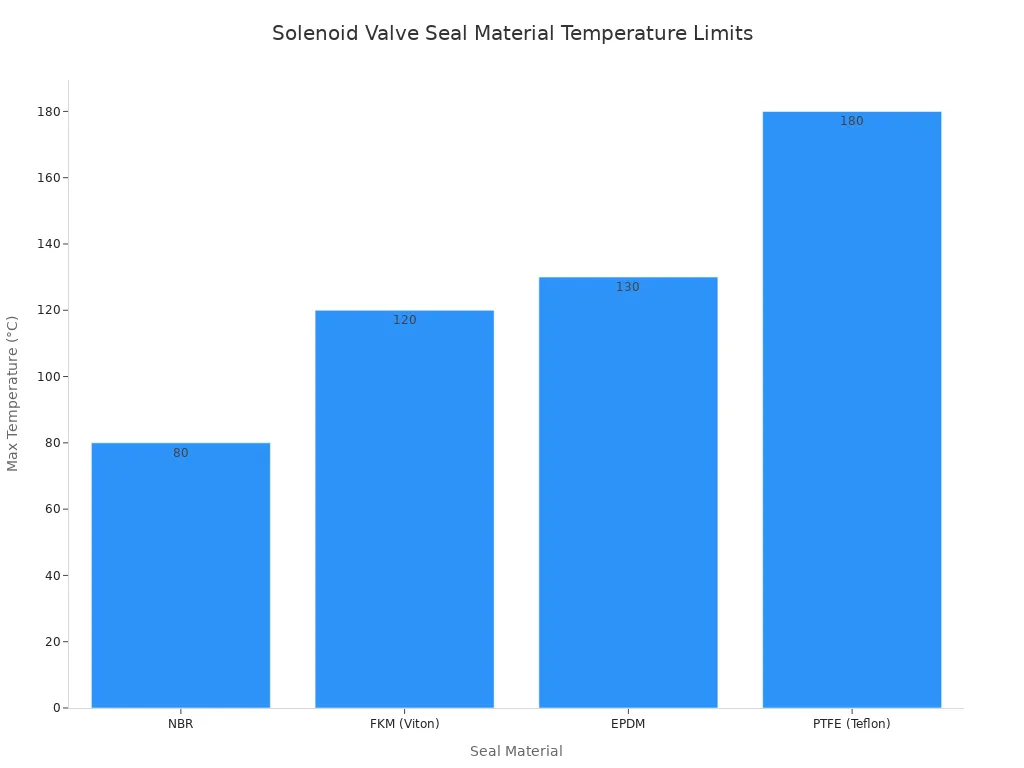

Seal Material Selection

Seal materials prevent leakage and ensure proper valve function. Their compatibility with the fluid and temperature range is critical.

| Material | Advantages | Disadvantages | Temperature Range |

|---|---|---|---|

| NBR | Good resistance to compression, tearing, wear; compatible with oil products, solvents, alcohol. | Sensitive to weather, moderate temperature resistance, unsuitable for brake fluid and polar solvents. | Up to 80°C |

| FKM (Viton) | Very good overall chemical resistance, good mechanical properties, resistance to compression set, suitable for high temperatures (not for hot water/steam), good resistance to oils and solvents. | Poor resistance to hot water and steam, swells at higher temperatures, unsuitable for polar solvents, certain esters and ethers, glycol based brake fluid. | -10 °C to 120 °C |

| EPDM | Very suitable for water, steam, ketones, alcohols, brake fluids, acids/alkalis in low concentrations; very good resistance to weather and ozone. | Poor resistance to oil, grease, and solvents; unsuitable for aromatic hydrocarbons. | -10 °C to 130 °C |

| PTFE (Teflon) | Resistant to almost all fluids, relatively hard, suitable for higher operating pressures and temperatures. | Not flexible, generally not used for low operating pressures. | -30 °C to 180 °C |

Different seal materials offer varying temperature limits and chemical resistance. NBR (Nitrile Rubber) works well for low to medium temperatures, typically up to 80°C. FKM (Fluorocarbon Rubber), also known as Viton, handles higher temperatures, up to 120°C, and offers excellent chemical resistance. EPDM suits hot water, steam, and many acids. PTFE (Teflon) provides exceptional chemical inertness and high-temperature resistance, reaching 180°C.

Internal Component Materials

Internal components, such as plungers, springs, and diaphragms, also require careful material selection. These parts often face direct contact with the fluid. Polytetrafluoroethylene (PTFE) and fluororubber frequently form diaphragms in anti-corrosion solenoid valves. They ensure complete isolation between the medium and other accessories, providing acid and alkali resistance. Stainless steel 316L, containing molybdenum, chromium, and nickel, resists various chemicals. It suits acidic and chloride-rich media. Hastelloy, a nickel alloy, offers strong defense against aggressive media corrosion and high stability at elevated temperatures. Polyvinylidene Fluoride (PVDF) provides excellent heat, abrasion, and impact resistance. Brass, while common, offers modest corrosion resistance. It is unsuitable for corrosive or acidic flow applications.

4. Electrical Specifications for Powering Your System

Electrical specifications are paramount for powering a solenoid valve system effectively. Buyers must carefully consider these factors.

Voltage and Power Requirements

Engineers must match the solenoid valve’s voltage to the system’s power supply. This prevents electrical damage and ensures proper operation. Common voltages for solenoid valves include DC 24V, 48V, and AC 127V, 220V, 380V. Different regions utilize specific voltage ranges:

| Voltage Range | Countries/Regions |

|---|---|

| 100V | Japan, North Korea |

| 110 ~ 130V | Taiwan, USA, Canada, Panama, Cuba, Lebanon, Mexico |

| 220 ~ 230V | UK, Germany, France, China, Singapore, Hong Kong (200V), Italy, Spain, Greece, Austria, Netherlands, Philippines, Thailand, Norway, India, New Zealand, Australia |

Power Consumption and Efficiency

Solenoid valve power consumption varies significantly. Several factors influence this, including the valve type, size, operating voltage, and number of coils. Larger valves generally consume more power. Higher operating voltages also typically lead to increased power consumption.

| Valve Type | Typical Power Consumption (Watts) |

|---|---|

| Small 2-Way Electric | 1 – 2 |

| Larger 2-Way Electric | 5 – 10+ |

| Medium 3-Way Manifold | 3 – 8 |

| Air-Actuated Solenoid | 2 – 5 (when energized) |

Proper sizing (Kv-value) prevents over-consumption. Indirect operated valves often consume less energy than direct-operated valves after initial actuation. Latching valves and bump-and-hold circuits can significantly reduce continuous power draw.

Duty Cycle Considerations

The duty cycle defines how long a solenoid valve can remain energized. Many solenoid coils feature a standard 100% duty cycle. This makes them suitable for continuous operation. Solenoids can provide duty cycles from 10% up to 100%. An application is continuous duty if the “On Time” approaches or exceeds the valve’s thermal stabilization time, typically around 30 minutes.

Enclosure Rating for Protection

The enclosure rating, often an IP (Ingress Protection) code, indicates the valve’s resistance to dust and water ingress. Selecting an appropriate IP rating protects internal electrical components from environmental hazards. This ensures reliable operation in various conditions.

5. Connection Type and Size for Seamless Integration

Proper connection type and size ensure seamless integration of solenoid valves into any system. This prevents leaks and maintains optimal flow.

Thread Type Standards

Various thread types define solenoid valve connections. Buyers must select the correct standard for their region and application. Common thread types include:

- NPT: American Standard Pipe Taper Thread

- FPT: American Standard Female Pipe Taper Thread

- NPSC: American Standard Straight Coupling Pipe Thread

- BSP: British Standard Pipe (encompasses BSPP and BSPT)

- BSPP: British Standard Pipe Parallel

- BSPT: British Standard Pipe Tapered

- GHT: Garden Hose Thread (US Standard)

- G Thread: British Gas – Parallel (same as BSPP)

- R Thread: British Tapered (same as BSPT)

DIN 43650 solenoid valve connectors also use specific thread types for cable entry. Form A connectors often feature PG 9, PG 11, M16, or 1/2″ NPT threads. Form B connectors use PG 9 or 1/2″ NPT threads. Form C connectors are exclusively available with PG 7 thread. M16 is a metric thread type, indicating the nominal diameter in millimeters. PG, or Panzergewinde, refers to German standards. NPT, or National Pipe Thread, is an American standard with tapered threads for sealing.

Port Size Matching

Matching the valve’s port size to the system’s connections is critical. Incompatibility between valve ports and system connections leads to turbulence, increased backpressure, and reduced flow efficiency. Oversized ports create dead zones. Undersized ports cause choke points that restrict flow or amplify wear. Proper port matching ensures controlled flow entry and exit velocity, increases throughput, and enhances long-term system availability. Oversized valves operate almost completely shut, making precise control difficult. They lead to ‘chattering,’ causing rapid wear on valve internals. Undersized valves act as bottlenecks, causing significant pressure drops. They generate noise, vibration, and heat due to wasted energy.

Mounting Options and Flexibility

Solenoid valves offer various mounting options for secure placement. Mounting screws are common for C-Frame and D-Frame solenoids, sinking directly into the frame. Threaded or slotted mounting is typical for tubular solenoids, using threads with a matching nut or slots with a retaining e-ring. Nest style mounting involves placing solenoids into a ‘nest’ within the customer’s product. Bracket mounting uses a separate bracket attached to the solenoid, which then affixes to the assembly.

6. Environmental Conditions for Safe Operation

Environmental conditions significantly influence a solenoid valve’s performance and lifespan. Buyers must consider these factors for safe and reliable operation.

Ambient Temperature Impact

Ambient temperature significantly impacts solenoid valve performance and lifespan. Both extreme cold and heat can alter a valve’s function.

- Impacts of Cold Temperatures:

- Changes in fluid viscosity

- Hardening of seals

- Material contraction

- Inconsistent actuation

- Impacts of Hot Temperatures:

- Overheating

- Degradation of seals

- Low fluid viscosity

- Electromagnetic changes

Humidity and Moisture Exposure

Humidity and moisture pose significant threats to solenoid valve electrical components.

- Moisture Absorption: Infiltration of moisture causes corrosion, electrical leakage, and material deterioration in electronic components. This damages packing materials, printed circuit boards (PCBs), and other component surfaces. It leads to short circuits and reduced insulating qualities, particularly affecting moisture-sensitive electronics.

- Electrical Leakage and Conductivity: High humidity increases the electrical conductivity of contaminants on component surfaces. This results in signal interference, short circuits, and leakage currents. This becomes especially problematic in high-voltage applications or environments with significant airborne pollutants.

- Material Compatibility and Degradation: Moisture hinders the effective interaction of materials within electrical components. High humidity causes delamination or reduced adhesion strength in moisture-sensitive adhesives or coatings. It also accelerates material degradation processes such as metal connection corrosion, polymer breakdown, and mold growth, compromising component reliability.

- Temperature and Humidity Cycling: The combined effect of temperature cycling (expansion and contraction) and humidity cycling (moisture absorption and loss) accelerates deterioration processes. This leads to heat stress, material fatigue, and the formation of microscopic fractures or voids, causing components to degrade over time.

High humidity allows water molecules to penetrate the insulation material of solenoid valve coils. This reduces insulation resistance and leads to electrical leakage. This leakage wastes energy, poses safety hazards, and can cause short circuits, damaging the coil and connected components. Moisture also accelerates the aging of insulation, making it brittle and prone to cracking over time.

Vibration and Shock Resistance

Solenoid valves operating in environments with high vibration or shock require robust construction. Manufacturers design these valves to withstand mechanical stress. This prevents internal component damage and maintains operational integrity.

Hazardous Area Certifications

Solenoid valves used in potentially explosive atmospheres require specific certifications. These certifications ensure safe operation in hazardous locations.

- UL Certification: This indicates compliance with Underwriters Laboratories (UL) testing standards for safety in North America (US and Canada).

- CE Marking/ATEX Certification: This is required for the European Union market. ATEX specifically certifies safety for use in potentially explosive environments, such as those with flammable gases and vapors.

- CSA Certification: This signifies that solenoid valves meet Canadian Standards Association (CSA) specifications. Some US hazardous applications also accept it.

- IECEx Certification: This international certification from the International Electrotechnical Commission indicates suitability for various hazardous applications globally.

The IECEx system classifies hazardous locations into zones (0, 1, 2 for flammable gases/vapors; 20, 21, 22 for combustible dusts). An IECEx certificate ensures a product meets global safety standards. This aids international trade and market access. ATEX approval, established under EU law, is crucial for machinery in hazardous environments. It minimizes injury and machinery failure risks. ATEX-certified products protect machinery operation in such conditions.

7. Certifications and Standards When Sourcing Solenoid Valves

Certifications and adherence to industry standards are crucial when Sourcing Solenoid Valves. They guarantee product quality, safety, and compliance with regulatory requirements. Buyers must verify these credentials.

Industry-Specific Certifications

Specific industries demand specialized certifications for solenoid valves. For instance, the food and beverage industry requires FDA (Food and Drug Administration) standards. These standards ensure food-safe design and contact with food products. This applies to food processing, brewing, beverage, and canning industries. Medical applications also have strict requirements. They follow the European Medical Device Regulation (MDR) and the US Food and Drug Administration’s medical device guidelines.

Safety Standards Compliance

Solenoid valves must comply with rigorous safety standards. These standards cover several aspects:

- Internal Construction and Port Orientation: Designs ensure safe fluid transfer, prevent leaks, and control media flow. This protects the valve and piping system.

- Sealing Mechanisms and Material Choices: Seals must withstand system pressure and chemical aggression. This is critical for safety in hazardous applications. Valve body materials resist corrosion and erosion, preventing leakage and maintaining structural integrity.

- External Safety Features and Enclosures: Robust enclosures protect internal components from environmental damage. Materials like stainless steel, plastic, or brass provide durability.

- Explosion-Proof and Intrinsically Safe Designs: These designs prevent ignition in explosive atmospheres. They are essential for hazardous applications.

Key certifications include IEC 61508 for functional safety and CE Marking for European market compliance. ATEX Certification is mandatory for equipment in explosive atmospheres, such as oil and gas industries. Safety Integrity Levels (SIL) measure system reliability, and PFDavg evaluates valve failure likelihood.

Quality Management Systems (ISO)

ISO certifications, particularly ISO 9001, signify a manufacturer’s commitment to quality. This certification improves company efficiency across all operations and production levels. It ensures continuous process control and product conformity through computerized networks. Manufacturers record each step for effective data analysis and complete traceability of components and finished products. Global certifications like ISO 9001 and CE compliance ensure reliability and safety in the solenoid valve manufacturing industry.

8. Manufacturer Reputation and Support for Reliability

A manufacturer’s reputation and the support they offer significantly influence the long-term reliability of solenoid valves. Buyers must consider these factors carefully.

Brand Reputation and Track Record

A strong brand reputation indicates a manufacturer’s commitment to quality and reliability. Companies like Burkert, Emerson, and ASCO boast long histories, some operating since the late 1800s. These established presences demonstrate sustained operation and extensive experience. Emerson, for example, maintains a global presence and a long history of innovation. Burkert has over 70 years of experience in liquid and gas process control. These companies are often trusted partners and leading providers, known for high-quality products and solutions.

Technical Support Availability

Reliable technical support is crucial for problem-solving and system optimization. Leading manufacturers often provide complementary design and engineering services. They offer direct access to sales and engineering teams for quick problem resolution, sometimes on the same day. This support extends to rapid prototyping and after-sale assistance. Specialized support for aircraft, missiles, nuclear, and scientific applications highlights their comprehensive capabilities.

Warranty and Return Policies

Understanding warranty and return policies protects investments. Many manufacturers offer limited warranties covering defects in workmanship and materials. For instance, electricsolenoidvalves.com provides a one-year limited warranty. Maxairtech offers an industry-leading three-year limited warranty on its products. These warranties typically require an original sales receipt and product return for inspection. Exclusions often include damage from misuse, improper installation, or exposure beyond specified limits.

Lead Times and Product Availability

Timely access to components is vital, especially in lean manufacturing environments. Delays in valve supply can disrupt production schedules, leading to extended lead times and assembly slowdowns. Buyers must verify a supplier’s inventory levels, standard lead times, and quick-shipment programs. This ensures consistent product availability and prevents costly operational interruptions.

This comprehensive checklist proves invaluable for Sourcing Solenoid Valves. It guides buyers, ensuring confident and informed purchasing decisions. Adhering to these eight critical factors minimizes risks. It also maximizes operational efficiency and system longevity.

FAQ

What is the difference between normally open and normally closed solenoid valves?

A normally closed (NC) valve remains shut when de-energized. It opens when energized. A normally open (NO) valve stays open without power. It closes when energized.

Why is material compatibility important for solenoid valves?

Material compatibility prevents premature wear, corrosion, and failure. It ensures the valve’s durability and longevity with the fluid and environment.

What does an IP rating signify for a solenoid valve?

An IP (Ingress Protection) rating indicates a valve’s resistance to dust and water ingress. It protects internal electrical components from environmental hazards.

Post time: Nov-17-2025