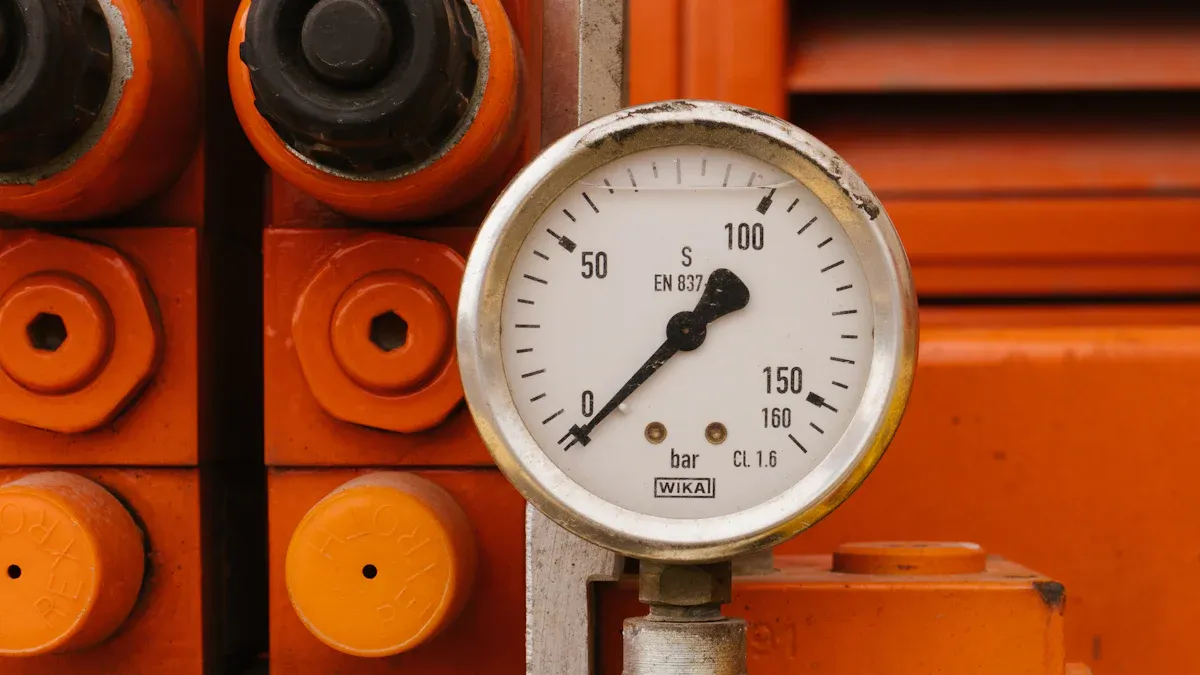

This case study demonstrates how implementing predictive maintenance, specifically leveraging Pressure Sensor data, resulted in an 18% improvement in machine uptime for a chemical plant. Unplanned outages significantly impact chemical businesses. Industry reports indicate the average loss per hour of downtime in the chemical sector is approximately $100,000.

Key Takeaways

- Using pressure sensors to predict machine problems helps chemical plants. It makes machines run 18% longer without stopping.

- This smart maintenance plan cut unexpected machine stops by 32%. It also lowered repair costs by 18%.

- The plant used data from sensors and AI to fix issues before they became big problems. This made the plant work better and safer.

The Challenge: Unreliable Machine Uptime and Reactive Maintenance

Frequent Unplanned Downtime

The chemical plant consistently faced significant challenges from frequent unplanned downtime. These unexpected stoppages disrupted production schedules and led to substantial financial losses. Each incident required immediate attention, diverting resources from planned activities and impacting overall operational efficiency.

High Maintenance Costs

The plant also struggled with high maintenance costs. Maintenance budgets typically allocate a significant portion, often 20-25%, to reactive repairs. This leaves a smaller percentage for preventive maintenance. This reactive approach meant the plant spent more on emergency fixes than on proactive measures to prevent failures.

Reactive Maintenance Limitations

Reactive maintenance strategies presented numerous limitations. They often led to increased safety risks for personnel, as emergency repairs can create hazardous working conditions. Equipment operating in a deteriorated state also produced lower quality output, resulting in waste and rework. Furthermore, reactive approaches made resource allocation inefficient, as teams constantly addressed emergencies instead of completing other important tasks. This approach also resulted in higher energy consumption from poorly maintained equipment and a loss of valuable data that could prevent future failures.

Root Causes of Pressure-Related Downtime

Specific pressure-related failures frequently caused machine downtime. Pressure surges and spikes were a leading cause of equipment failure in pipes and machinery. Fluctuating pressure also led to operational inefficiencies and process disruptions. One notable incident involved a sudden shutdown due to a Pressure Sensor failure. Frozen impulse lines caused distorted signals, activating the interlock system and halting production. This incident alone resulted in over $1 million in direct losses, highlighting the critical need for better pressure monitoring and maintenance.

The Solution: Pressure Sensor-Driven Predictive Maintenance

Why Pressure Sensors for Critical Assets?

The plant recognized the need for a proactive approach. They focused on critical assets where pressure fluctuations often led to failures. Pressure vessels, for example, are highly susceptible to these issues. Operating above maximum allowable working pressures causes significant stress. Improper sizing or setting of relief devices also contributes to problems. Faulty maintenance and irregular testing of relief devices can lead to their improper operation. Vessels also fail due to fatigue from repeated pressurization. General thinning from corrosion or erosion, localized corrosion, and stress corrosion cracking weaken them. Embrittlement, holes, and leaks also compromise vessel integrity. Infrequent inspections often miss these developing issues. Improper repairs, especially welding and annealing, can further weaken a vessel. Over-pressuring from exothermic reactions or polymerization also causes failures. Finally, vessel exposure to fire presents a severe risk. Monitoring pressure in these assets became a top priority.

Pressure Sensor Deployment Strategy

The team developed a comprehensive deployment strategy for the new system. They identified key points in the process where pressure data was most critical. Engineers strategically placed Pressure Sensor devices on pumps, valves, and pipelines. They focused on areas known for historical failures or high operational stress. This targeted approach ensured the collection of relevant data from the most vulnerable components. The strategy also included redundant sensor placement for critical points. This provided data integrity and backup in case of individual sensor failure.

Data Acquisition and AI-Powered Analytics Platform

Data collection formed the foundation of the new system. The plant implemented a robust data acquisition system. This system continuously gathered pressure readings from all deployed sensors. For monitoring pressure fluctuations within a 0-50Hz range, the system used sampling rates between 250-500Hz. High-quality sensors achieved a 16-bit effective resolution when sampled at 1kHz. This high-frequency sampling captured even subtle changes in pressure. All collected data fed into an AI-powered analytics platform. This platform processed vast amounts of real-time data. It identified patterns and deviations that indicated potential issues.

Predictive Model Development with Machine Learning

The analytics platform used advanced machine learning models to develop predictive capabilities. Engineers built algorithms to analyze the pressure data. They employed various techniques, including advanced pattern recognition and anomaly detection algorithms. These unsupervised learning models identified unusual pressure behaviors. Deep learning models were also used for complex pattern recognition. Neural Networks proved effective for analyzing rotating machinery vibration, which often correlates with pressure issues. Ensemble Methods were applied to systems like HVAC, while Time Series Analysis helped predict failures in pumps and compressors. For electrical systems, pattern recognition was key. Anomaly detection also proved useful for conveyor systems. Other models included Regression Analysis, Classification Models, and Support Vector Machines (SVMs). Random Forests and Logistic Regression also contributed to the predictive framework. These models learned from historical data. They then predicted future equipment failures based on real-time pressure readings.

Implementation Process: From Pressure Data to Actionable Insights

Data Collection and Baseline Establishment

The plant initiated the process by collecting extensive pressure data. They established a baseline for normal operating conditions. Engineers selected instruments with ranges that did not extend significantly beyond the required operating range. They also ensured accuracy within ±0.25 Pa. This included part of the negative scale in the instrument range to capture low or negative pressures. The team utilized Statistical Process Control (SPC) tools like control charts for continuous monitoring. These charts visually represented process variability. This allowed early detection of trends or shifts indicating deviations. They also defined and documented safe operating ranges for all critical process variables.

Algorithm Refinement for Pressure Anomalies

The team continuously refined the algorithms for pressure anomaly detection. They evaluated the accuracy and effectiveness of these algorithms using specific metrics. These included Accuracy, F1 Score, Precision, and Recall. For instance, Random Forest models showed a TEP Accuracy of 0.90 ± 0.02 and an F1 Score of 0.89 ± 0.03. They also considered operational efficiency metrics like equipment downtime and maintenance costs. Computational metrics such as anomaly detection accuracy and data processing speed guided further improvements. This iterative process ensured the predictive models accurately identified potential issues from Pressure Sensor data.

Maintenance Workflow Integration and Alert Systems

Integrating the predictive insights into the maintenance workflow was a critical step. The system automatically generated alerts when it detected pressure anomalies. These alerts provided maintenance teams with early warnings. This allowed them to schedule interventions proactively. The plant established clear protocols for responding to these alerts. This ensured a swift transition from detection to action. This integration minimized reactive repairs and optimized resource allocation.

Personnel Training for Predictive Tools

The plant invested significantly in personnel training. This ensured effective utilization of the new predictive maintenance tools. Training programs covered fundamentals of maintenance management and best approaches to maintenance. They also included predictive maintenance strategies, technologies, and tools. Personnel learned about data collection in a PdM program and how to leverage CMMS for asset management. The training also focused on recognizing visual inspection as a component of a PdM program. This comprehensive training empowered the maintenance team to interpret data and act on predictive insights.

The Results: A Tangible 18% Increase in Machine Uptime

Direct Evidence of Uptime Improvement

The implementation of pressure sensor-driven predictive maintenance brought clear and measurable benefits. The chemical plant experienced an 18% increase in overall machine uptime. This significant improvement directly translated into more operational hours for critical equipment. It allowed the plant to meet production targets more consistently. The new system moved the plant away from reactive fixes. It enabled proactive interventions based on real-time data. This shift ensured machines ran longer and more reliably.

Quantifiable Reduction in Unplanned Incidents

The predictive maintenance system dramatically reduced unexpected disruptions. The plant saw a 32% reduction in unplanned downtime incidents. This figure highlights the system’s effectiveness in preventing sudden equipment failures. Fewer unplanned stops meant production schedules remained on track. It also reduced the need for emergency repairs. This substantial decrease in incidents directly contributed to the overall uptime improvement. It also created a more stable and predictable operating environment.

Decreased Maintenance Costs

The proactive approach of predictive maintenance led to significant cost savings. The plant achieved an 18% reduction in overall maintenance costs. This saving came from better planning and optimized resource use. It also eliminated waste across various expense categories. These categories included labor, parts, and contractor services. Emergency response premiums also saw reductions. Industry studies confirm these reductions. Savings can reach up to 40% over reactive maintenance strategies.

Specific cost categories showed even more dramatic reductions:

| Cost Category | Reduction Percentage |

|---|---|

| Emergency Repairs | 75% |

| Obsolescence Reduction | 60% |

| Administrative Costs | 40% |

| Inventory Costs | 35% |

| Outsourcing Strategy | 35% |

| Contractor Management | 30% |

| Scheduling Optimization | 25% |

| Procurement Savings | 25% |

| Cross-Training Programs | 20% |

| Energy Consumption | 20-30% |

| Performance Incentives | 18% |

| Skills Assessment | 15% |

The most significant savings came from emergency repairs, which decreased by 75%. Reducing obsolescence also saved 60%. These figures demonstrate the power of predictive insights. They allowed the plant to address issues before they became costly emergencies.

Improved Operational Efficiency and Production

The increased machine uptime and reduced incidents directly boosted operational efficiency. Production lines ran more smoothly and consistently. The plant experienced fewer bottlenecks and delays. This led to a higher overall production output. Resources, including personnel and materials, were utilized more effectively. Teams could focus on planned maintenance and improvements. They spent less time reacting to crises. This created a more streamlined and productive operation.

Qualitative Benefits and Enhanced Safety

Beyond the numbers, the predictive maintenance system brought several qualitative benefits. Employee morale improved significantly. Workers felt more confident in the reliability of their equipment. The proactive approach also enhanced safety. The system identified potential hazards before they escalated. This allowed for timely interventions. It reduced the risk of accidents and injuries. Better data and insights led to more informed decision-making across all operational levels. The plant fostered a culture of continuous improvement and proactive problem-solving.

Key Takeaways and Future Outlook for Pressure Sensor Applications

Critical Success Factors

Several key factors contributed significantly to the success of the predictive maintenance implementation. Cross-functional alignment proved crucial for integrating predictive maintenance into daily operations. The plant started with pilot programs. These programs tested the system, measured its impact, and refined it before scaling across other lines. The team addressed challenges like high initial investment by starting small and scaling progressively. They overcame resistance to change through early engagement, training, and showcasing benefits. Ensuring data integrity was also vital. This involved proper calibration, validation, and audits to maintain accuracy, completeness, and consistency. Prioritizing industrial cybersecurity secured data transmission, implemented access controls, and regularly updated software. The plant used sensors for continuous condition monitoring. These sensors provided real-time insights on vibration, temperature, pressure, noise, oil quality, and electrical signals. Data analysis and machine learning algorithms interpreted this sensor data. They identified patterns, predicted remaining useful life, detected anomalies, and triggered alerts. Integrating condition monitoring systems with broader maintenance and production ecosystems, such as CMMS and ERP, translated insights into timely actions. Finally, training teams on the new system, how to act on predictive insights, and updated workflows established clear decision-making protocols.

Lessons Learned

The implementation faced unexpected challenges. Data migration presented issues. These included incomplete data transfers and formatting inconsistencies. Missing customer records and property information also caused problems. Technical integration issues arose. Third-party software conflicts caused data sync errors. Custom report formats did not display expected results. Existing systems sometimes failed to integrate smoothly. User adoption resistance was another hurdle. Employees reverted to old processes. Field crews used paper timesheets instead of mobile apps. Office staff maintained parallel spreadsheets. Managers did not fully utilize reporting capabilities.

The plant overcame these challenges through several strategies. Preventative measures included pre-implementation risk assessments. They established rollback procedures and created communication escalation matrices. Resource allocation planning also helped. The team shifted from preventing every issue to developing skills for efficient problem-solving. They leveraged support resources. These included implementation services, professional services, and customer support for troubleshooting. Strategic guidance from Customer Success Managers also proved valuable.

This case study unequivocally demonstrates that a targeted predictive maintenance strategy, specifically driven by pressure sensor data, can yield significant and measurable improvements in machine uptime, directly impacting operational efficiency and profitability. The chemical plant achieved an 18% uptime increase and reduced maintenance costs. This proactive approach offers a clear path for other organizations to enhance their operational performance and achieve substantial savings.

FAQ

What is predictive maintenance?

Predictive maintenance uses data analytics to forecast equipment failures. It allows proactive repairs before breakdowns occur. This approach optimizes maintenance schedules and reduces downtime.

How do pressure sensors contribute to predictive maintenance?

Pressure sensors monitor critical asset conditions in real-time. They detect anomalies indicating potential issues. This data feeds into AI models, predicting failures before they happen. This data feeds into AI models, predicting failures before they happen, leading to improved performance.

What were the main benefits for the chemical plant?

The plant achieved an 18% increase in machine uptime. It also saw a 32% reduction in unplanned incidents. Maintenance costs decreased by 18%, improving overall efficiency.

Post time: Dec-12-2025