A proactive solenoid coil replacement program can reduce unplanned downtime by 40%. This case study demonstrates its success. Unplanned downtime costs manufacturing facilities substantial amounts, often exceeding $20,000 per hour. This post details how a facility shifted from reactive maintenance for its Solenoid Coil components. They moved to a scheduled replacement strategy for critical Solenoid Coils.

Key Takeaways

- Proactive solenoid coil replacement reduces unplanned downtime by 40%. This saves money and makes operations smoother.

- Moving from fixing things after they break to planned maintenance helps avoid costly surprises. It makes equipment last longer.

- Using new tools like smart sensors and data analysis helps predict problems. This allows for repairs before equipment fails.

The Challenge: High Unplanned Downtime from Solenoid Coil Failures

Identifying Frequent Solenoid Coil Failures

Manufacturing facilities often face significant operational hurdles due to equipment malfunctions. A common culprit behind unplanned downtime is the frequent failure of critical components like the Solenoid Coil. These failures stem from various issues. Incorrect voltage or frequency application can damage the coil. Power surges, known as electrical spikes, also cause irreparable damage. Environmental factors, such as water ingress or liquid contamination, lead to failure if the coil’s IP rating is insufficient. Furthermore, debris, sediment, or particle contamination can restrict the armature’s movement, causing the coil to overwork and overheat.

Quantifying the Costs of Unplanned Downtime

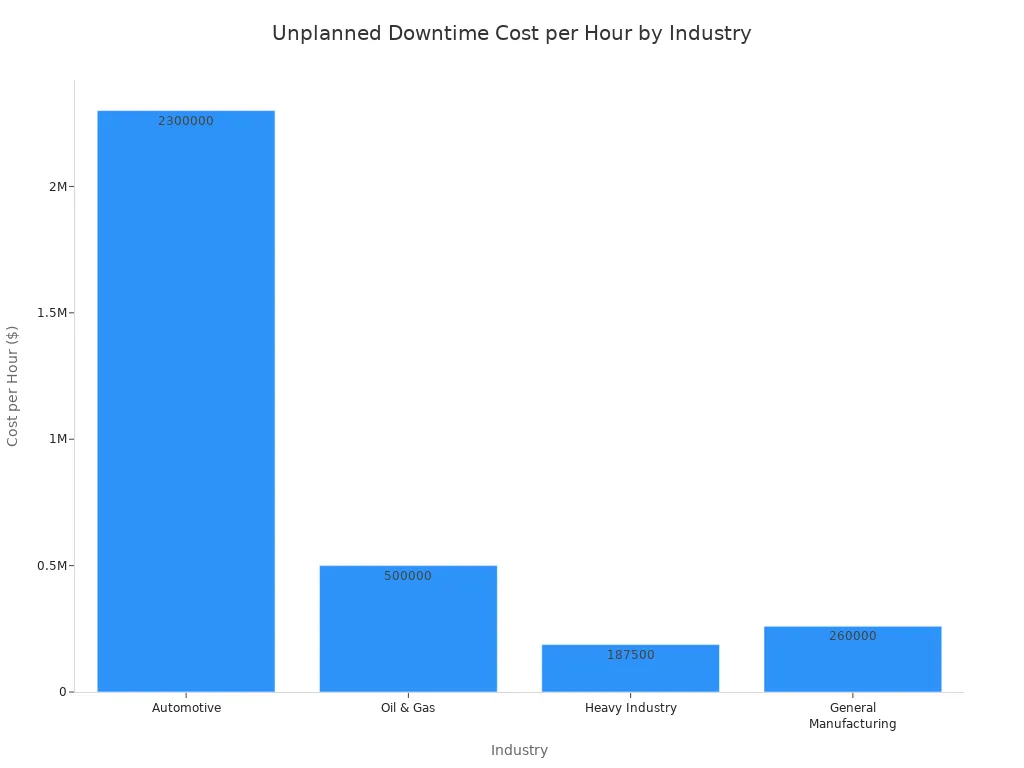

Unplanned downtime carries substantial financial burdens. Direct costs can be staggering across industries. For example, general manufacturing experiences an average loss of $260,000 per hour due to downtime.

Beyond direct financial losses, indirect costs also impact operations. These include:

- Overtime Expenses: Increased labor costs occur as employees work extra hours to catch up on production.

- Reputation Damage: Downtime leads to missed deadlines and dissatisfied customers, harming the company’s standing.

- Decreased Morale: Frequent disruptions frustrate employees, reducing productivity.

- Safety Risks: Rushed repairs create hazards for workers. Reputational damage, though difficult to quantify, can be devastating. Customer trust can vanish quickly, impacting future business and investor confidence.

Limitations of Reactive Maintenance Approaches

Relying solely on reactive maintenance for critical components presents numerous disadvantages. This approach means addressing issues only after they occur.

- Increased Safety Risks: Equipment failures lead to dangerous working conditions and potential injuries.

- Lower Production Quality: Deteriorated equipment produces substandard output, causing waste and rework.

- Inefficient Resource Allocation: Reactive maintenance makes it difficult to manage resources, leading to higher labor costs and technician burnout.

- Higher Energy Consumption: Poorly maintained equipment uses more energy.

- Loss of Data and Learning Opportunities: This approach prevents tracking deterioration patterns and optimizing maintenance schedules.

- Interference with Planned Maintenance: Emergency repairs delay or cancel scheduled tasks, creating a backlog.

- Lack of Root Cause Analysis: Reactive fixes often address symptoms, not underlying problems, leading to repeat failures.

- Higher Costs from Emergency Repairs: Emergency services are almost always more expensive than scheduled maintenance.

- Shortened Equipment Lifespan: Equipment maintained reactively has a significantly shorter operational life.

Implementing a Proactive Solenoid Coil Replacement Program

Designing the Proactive Replacement Strategy

Transitioning from reactive to proactive maintenance requires a structured approach. Facilities must first design a comprehensive strategy. This process begins with selecting a project leader. This individual possesses strong maintenance knowledge and oversees planning and implementation. Next, facilities involve key stakeholders. This includes front-line technicians, production operators, engineers, and management. Their input ensures a well-rounded plan. A crucial step involves conducting a maintenance audit. This audit evaluates current practices, identifies weaknesses, and pinpoints critical equipment. Following the audit, teams develop a cost-benefit analysis. This analysis assesses potential cost savings and operational improvements from proactive maintenance. To manage the transition effectively, facilities start small and scale gradually. They begin with a pilot program on critical equipment before full organizational implementation. This approach allows for adjustments and learning. Finally, organizations focus on building a data-driven culture. This promotes decision-making based on data and continuous improvement.

Criteria for Critical Solenoid Coil Selection

Identifying critical assets forms the backbone of any proactive maintenance program. Facilities must determine which assets are vital to business operations. This prioritization guides maintenance efforts. For example, a Solenoid Coil controlling a main production line valve is critical. Its failure would halt production. Teams establish an asset registry, a comprehensive list of all assets requiring maintenance. This ensures all components are accounted for. They then identify critical equipment. This equipment is essential for operations and could cause significant downtime if it fails. Factors for criticality include the asset’s role in the production process, its failure rate, and the cost of its replacement or repair. Prioritizing these components ensures resources focus on areas with the highest impact on operational continuity.

Planning and Scheduling Solenoid Coil Replacements

Effective planning and scheduling are essential for a successful proactive program. Facilities create a proactive maintenance schedule. This schedule establishes a start date and assigns maintenance activities to specific days. It considers workload balance and production periods. Maintenance management software organizes all maintenance work. This software allows teams to create and assign work orders, schedule recurring tasks, track inventory, and monitor equipment performance. Computerized Maintenance Management Systems (CMMS) are particularly effective. They offer intuitive dashboards and features that make advanced maintenance processes logical and accessible. CMMS asset management and reporting functions convert information on equipment lifespan, performance, and repair into tangible, actionable metrics. Internet of Things (IoT) devices provide real-time monitoring of equipment conditions. This enables teams to detect anomalies and address them before they escalate into failures. Integrating IoT technologies with a CMMS allows for seamless data flow and actionable insights. Advanced analytics tools, including machine learning algorithms, help interpret vast amounts of data. These tools predict potential failures and optimize maintenance schedules. Automated preventive maintenance scheduling within these systems uses asset data and equipment manuals. This builds a preventive maintenance plan, often supported by AI assistants.

Resource Allocation for Program Success

Proper resource allocation ensures the proactive program’s long-term success. This includes investing in training and reskilling personnel. Maintenance staff must understand proactive maintenance principles, data analysis, and new techniques. Essential training programs for technicians involved in proactive Solenoid Coil replacement include foundational knowledge in electrical systems and electronic control systems. For electrical systems, technicians learn to adhere to safety rules, interpret schematics, measure voltage, current, and resistance, and install and test various electrical components. They also troubleshoot electrical motor relay control circuits and solenoid-operated fluid power relay control circuits. Hands-on skills develop through systems like AC/DC Electricity, Motor Control, and Industrial Wiring Systems. For electronic control systems, training covers safety rules, connecting and testing DC power supplies, installing and testing solid-state relays, analog electronic sensors, and basic PLC components. Technicians also learn to troubleshoot PLC and controlled components. Hands-on skills are developed through systems like Power & Control Electronics and PLC Troubleshooting. This comprehensive training ensures technicians possess the expertise to execute proactive maintenance tasks effectively and safely.

Achieved Results and Key Takeaways from the Solenoid Coil Program

The 40% Reduction in Unplanned Downtime

The proactive solenoid coil replacement program delivered significant results. The manufacturing facility achieved a 40% reduction in unplanned downtime. This outcome aligns with industry research. Manufacturing facilities often lose between 5% and 20% of their annual productivity due to unexpected stoppages. Companies that implement proactive maintenance strategies can reduce downtime by up to 40%. This case study demonstrates that potential.

The facility measured this success using several key metrics. Mean Time Between Failures (MTBF) significantly improved. This metric tracks the average time equipment operates without issues. A higher MTBF directly boosts Overall Equipment Effectiveness (OEE). The Planned Maintenance Percentage (PMP) also increased. This metric shows the proportion of total maintenance hours spent on scheduled tasks. A high PMP indicates a strong proactive maintenance culture. It means the facility allocates resources to preventive and predictive maintenance. This strengthens asset reliability and reduces overall maintenance costs. Equipment Downtime, specifically unexpected downtime, saw a sharp decrease. Tracking this metric is crucial. High downtime often signals inadequate preventive maintenance. The Reactive Maintenance Percentage also dropped. This metric tracks unplanned maintenance work. A lower percentage confirms a more proactive approach. This leads to reduced downtime and extends equipment lifespan. Organizations relying on reactive maintenance experience much more downtime than proactive operations.

Financial and Operational Benefits Realized

The proactive solenoid coil program brought substantial financial and operational benefits. Financially, the return on investment (ROI) was impressive. A study by Jones Lang LaSalle, in partnership with a large telecommunications firm, found that preventive maintenance programs yielded a 545% ROI. This facility experienced similar positive financial returns. Reduced unplanned downtime meant fewer emergency repairs. It also meant less overtime for staff and avoided production losses.

Operationally, the facility saw many improvements. Proactive maintenance anticipates and monitors potential equipment failures. It addresses them before they escalate. This leads to increased productivity and fewer breakdowns. Preventive maintenance is a systematic and scheduled activity. It prevents equipment failures and ensures reliable operation. This enhances asset durability and boosts operational efficiency. It also reduces downtime by proactively handling issues. The facility experienced reduced downtime due to fewer malfunctions. Equipment reliability, availability, and uptime all improved. This led to increased productivity and long-term savings. Regular proactive maintenance ensures equipment performs optimally. This results in increased productivity and operational efficiency. It also improves end-product quality. The program ensured optimal equipment operation. It minimized disruptions from unexpected breakdowns. This significantly improved overall productivity.

Best Practices for Proactive Solenoid Coil Maintenance

Implementing best practices ensures the continued success of a proactive maintenance program. Regular inspection of solenoid coils is vital. Technicians must check the solenoid valve coil for cracks or signs of burnout. They should never power up the coil if it is not installed on the valve stem. This can cause high current and damage. Preventing moisture penetration into the coil is also crucial. Moisture can cause valve failure. Technicians must inspect connections to the coil for any damage or corrosion.

Protecting coils from environmental factors is another key practice. For outdoor or wet installations, facilities should use IP-rated enclosures. These prevent water ingress. Monitoring for signs of failure is also important. Watch for indicators like buzzing noises, excessive heat, or sluggish actuation. These can signal coil degradation. Regular electrical testing and functional inspections are necessary. Use appropriate test equipment to check parameters like coil resistance, current, and voltage. Ensure the solenoid valve’s opening and closing actions are normal. Check for abnormal noise or vibration. Regularly inspect connections and cables for loose fasteners, frayed, or exposed wires. Address any damage, corrosion, or scratches promptly. This prevents performance issues.

Advanced technologies enhance proactive maintenance effectiveness. AI-based predictive maintenance scheduling uses algorithms to forecast equipment failures. It optimizes maintenance timelines by analyzing historical data and sensor readings. Machine learning optimizes resource allocation for maintenance tasks. It considers equipment criticality, personnel availability, and spare parts. Real-time monitoring and adaptive scheduling systems continuously track equipment performance. They dynamically adjust maintenance schedules for timely interventions. Integrating AI with IoT creates intelligent maintenance systems. These systems collect real-time data, analyze it with AI, and provide actionable insights. Tools like thermal imaging and resistance testing also help. Condition monitoring systems track real-time performance of solenoid valves. They detect anomalies before they lead to failures. Predictive maintenance technologies anticipate problems by analyzing data from these systems.

A proactive Solenoid Coil replacement program proved highly effective. It led to a 40% reduction in unplanned downtime. The program also delivered significant operational and financial benefits. This case study highlights the power of strategic maintenance planning. It optimizes industrial operations.

FAQ

What is a solenoid coil?

A solenoid coil is an electromagnetic device. It converts electrical energy into linear motion. This motion controls valves or other mechanical components in industrial systems.

Why do solenoid coils fail frequently?

Solenoid coils fail due to several factors. These include incorrect voltage, power surges, and environmental issues like moisture. Contamination can also cause them to overwork and overheat.

What are the main benefits of a proactive replacement program?

A proactive program significantly reduces unplanned downtime. It improves equipment reliability and extends asset lifespan. This approach also leads to substantial financial savings and increased productivity.

Post time: Jan-06-2026