Material selection is paramount for control valve reliability. Approximately 30% of control valve failures occur prematurely due to improper material choices. This critical decision prevents control valve failure. Incorrect material or accessory selections lead to corrosion and reduced control accuracy. Proper material selection directly impacts operational safety and efficiency.

Key Takeaways

- Choosing the right material for control valves is very important. It stops valves from breaking down too soon. This helps keep things safe and working well.

- Different types of corrosion can harm control valves. Things like temperature, how strong chemicals are, and even tiny chemicals can affect how long a valve lasts. Always check what materials work best with your chemicals.

- You can use special metals or non-metal materials for valves. Non-metals like plastics are good for strong chemicals. Always look at charts and talk to experts to pick the best material. This saves money and problems later.

Understanding Corrosion in Control Valves

Defining Corrosion Types Affecting Control Valves

Corrosion represents a significant threat to the integrity and operational lifespan of industrial equipment. It involves the deterioration of a material, typically a metal, due to chemical or electrochemical reactions with its environment. Several distinct types of corrosion affect control valves in industrial settings.

General corrosion, also known as uniform corrosion, affects the entire surface of a metal component. It appears as rust, often when metal reacts with water and oxidizes. Galvanic corrosion occurs when two dissimilar metals contact each other within a corrosive electrolyte, forming a galvanic couple where the less noble metal corrodes faster. Localized corrosion attacks specific sections of a metal component. This type includes pitting, crevice corrosion, and filiform corrosion, proving harder to detect and repair than general corrosion.

Other critical types include stress corrosion cracking (SCC), which results from a combination of a corrosive environment, specific alloys, and tensile stress. Hydrogen diffuses into anodic sites, building pressure and causing cracks. Intergranular corrosion happens when impurities at grain boundaries within an alloy corrode, weakening the metal. Furthermore, fluid composition drives specific corrosion types. In oil and gas, CO2 and H2S, when dissolved in liquid water, form acidic compounds. This leads to H2S-dominated (sour) corrosion, causing pitting, or CO2-dominated (sweet) corrosion, characterized by general corrosion. Microbially induced corrosion (MIC) also occurs when valves are exposed to sulfate-reducing bacteria (SRB) and organic sediments, leading to highly localized corrosion.

Principles of Chemical Compatibility for Control Valves

Chemical compatibility is crucial for ensuring the longevity and reliable performance of a control valve. It refers to how all exposed materials, including seals and trim components, interact with the controlled fluid. This interaction dictates the material selection. For highly corrosive applications, materials like Hastelloy or titanium are recommended. Conversely, less corrosive environments may permit the use of cast iron or brass, directly linking fluid properties and material selection.

The choice of material for wetted parts, such as metals, thermoplastics, ceramics, and elastomers, depends on the fluid’s properties and required mechanical strength. Environmental factors significantly influence material resistance to corrosion or chemical damage. These factors include concentration, temperature, the presence of abrasives, impurities, and entrained gases. Materials like stainless steel resist corrosion due to a self-repairing protective oxide layer. For severe conditions, nickel-based superalloys offer superior resistance. Consulting chemical compatibility charts from manufacturers and conducting field tests are essential for definitive material selection.

Key Factors Influencing Control Valve Material Performance

Temperature Effects on Control Valve Material Integrity

Temperature significantly impacts control valve material integrity. Elevated temperatures cause elastomeric materials to harden, lose flexibility, and potentially crack. These changes are often irreversible. For instance, silicone and fluorocarbon elastomers can exceed 400°F (230°C), while Neoprene and Nitrile have lower maximal operating temperatures, typically 210 to 250°F (100 – 120°C). Metals also exhibit reduced strength at higher temperatures, which decreases pressure ratings.

To combat corrosion in high-temperature applications, protective internal linings like high-temperature epoxy coatings are effective. These coatings offer chemical resistance and remain flexible to prevent cracking. Carbon steel grades like ASTM A216 (WCA, WCB, WCC) have a maximum limit of 800°F. Stainless steel grades vary; Grade 304 and 316 can operate continuously at 1,700°F (925°C), while Grade 410 is limited to 1,300°F (705°C). API Trim 17, using materials like 347 stainless steel, offers good corrosion and high-temperature resistance up to 800°C. Ceramic-lined ball valves suit corrosive media with abrasive solids at temperatures up to 1740°F.

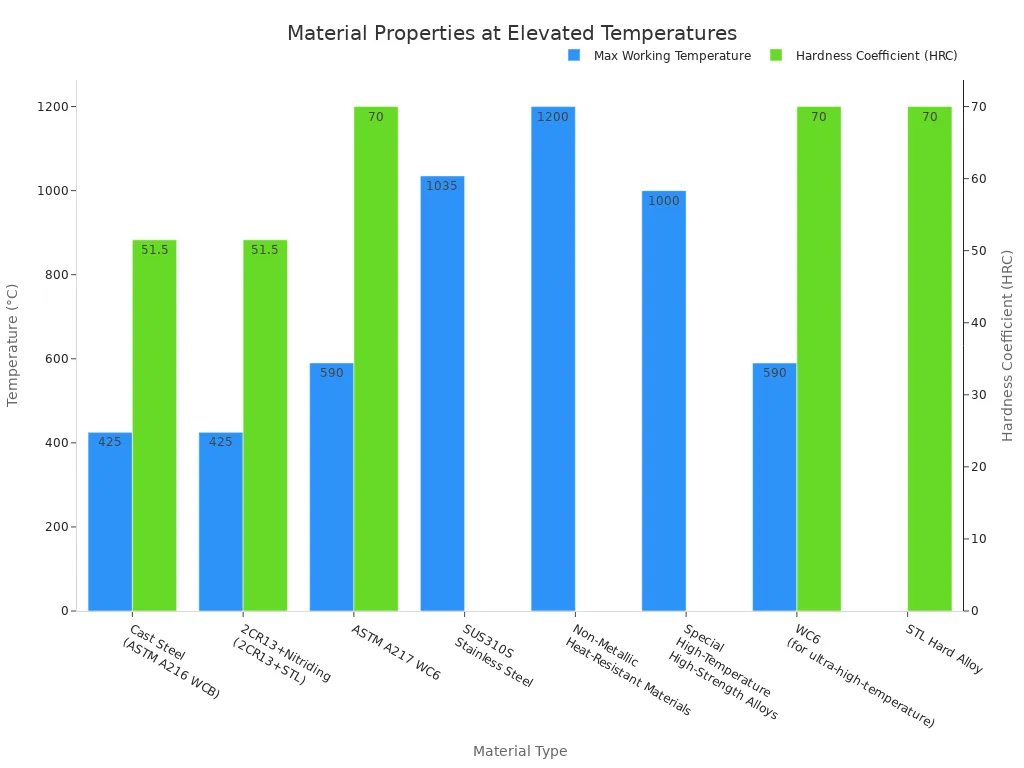

| Material Type | Max Working Temperature | Hardness Coefficient | Key Properties & Applications |

|---|---|---|---|

| Cast Steel (ASTM A216 WCB) | 425°C | HRC45-58 | Good mechanical and high-temperature performance, withstands high pressure and temperature, good machinability and weldability, suitable for large ball valves. |

| 2CR13+Nitriding (2CR13+STL) | 250°C-425°C | HRC45-58 | Improved surface hardness and wear resistance after nitriding, good corrosion resistance, used for ball of high-temperature ball valves. |

| STL Hard Alloy | Extremely high | HRC68-72 | Extremely high hardness and wear resistance, good corrosion resistance, used for sealing surface of high-temperature ball valves. |

| ASTM A217 WC6 | 590°C | HRC68-72 | High heat resistance and mechanical properties, good corrosion and wear resistance, used for valve body and internal components of ultra-high-temperature ball valves. |

| SUS310S Stainless Steel | 1035°C | N/A | Good high-temperature stability and mechanical properties (with controlled carbon content), good corrosion resistance, used in extremely high-temperature environments. |

Concentration of Corrosive Media for Control Valves

The concentration of corrosive media directly influences material degradation. Higher concentrations often demand more robust materials. For dilute acid solutions, standard stainless steel may suffice. However, concentrated acids require super-austenitic or nickel-based alloys. The pH concentration (acidity or alkalinity) and oxygen levels in the pipeline also affect electrochemical corrosion rates.

| Corrosive Compound & Concentration | Temperature | Recommended Valve Material |

|---|---|---|

| High concentrations of sulfur (with H2SO4 formation) | N/A | Alloy stainless steel (e.g., Alloy-20) |

| H2SO4 | Low-pressure, low-temperature | Fluoroplastic valves |

| Hydrochloric acid (<30%) | Below 120°F (50°C) | Steel alloys with molybdenum |

| Hydrochloric acid | Up to 300°F (150°C) | Non-metallic valve materials |

| Nitric acid | High-temperature | Titanium alloy valves |

Pressure and Flow Rate Considerations for Control Valves

Flow rate significantly influences erosion-corrosion, particularly flow-accelerated corrosion. High flow velocities can degrade materials like low-alloy steel and carbon steel in various systems. While high pressure is relevant to valve design, its specific influence on erosion-corrosion mechanisms in control valves is primarily linked to flow characteristics and velocity.

Impact of Trace Chemicals on Control Valve Materials

Trace chemicals, even in small quantities, can significantly impact material performance. These minor constituents may act as catalysts, accelerating corrosion, or they might form unexpected corrosive compounds. Therefore, a thorough analysis of all process stream components, including trace elements, is crucial for proper material selection.

Metallic Control Valve Materials for Corrosive Service

Metallic materials form the backbone of many industrial applications, including control valves, due to their strength and versatility. However, selecting the correct metal for corrosive environments requires careful consideration of specific process conditions.

Stainless Steels for Control Valves: Grades and Applications

Stainless steels are a popular choice for control valves in corrosive service. They offer excellent corrosion resistance in many applications. Grade 304, a common 300 series material, provides good general corrosion resistance. Grade 316 offers superior resistance to various acids, including sulfuric, sulfurous, and acetic acids, and also resists pitting corrosion. This makes it suitable for more aggressive environments.

The austenitic family includes common stainless steel grades for valves such as 304, 304L, 316, and 316L. Grade 304L, a low-carbon stainless steel, performs similarly to 304 in normal conditions. It particularly excels in resisting intergranular corrosion after welding or stress relief. Grade 316L (low carbon) provides excellent resistance to intergranular and grain-boundary corrosion. It shares characteristics with 316 steel. The addition of molybdenum makes 316L ideal for very severe conditions, such as seawater applications.

Specialized stainless steels also exist for unique challenges:

- CarTech 20Cb-3® stainless: This highly alloyed material offers special resistance to sulfuric acid. It also protects against welding-induced corrosion loss. It provides superior resistance to hundreds of industrial and process corrodents, especially in valved fluid piping systems.

- CarTech 430 stainless: This less costly option provides adequate corrosion resistance for foodstuffs, fresh water, and non-marine atmospheric conditions. It is less resistant than CarTech 304.

- CarTech 405 stainless: This material offers minimum corrosion resistance. It suits soap, alcohol, crude oil, gasoline, mercury, and other mild reagents.

- CarTech 410 stainless: Applications requiring low-level corrosion resistance but higher strength use this material. It offers good strength, ductility, and oxidation resistance up to 649°C (1200°F).

- CarTech 420 stainless: This grade provides greater strength and hardness at the same corrosion resistance level as 410. It has higher strength and wear resistance in hardened and tempered conditions.

- CarTech 440C stainless: This material combines the lowest corrosion resistance with very high hardness and strength. It suits products needing high hardness and wear resistance.

- CarTech 431 stainless: This grade offers a good combination of corrosion resistance, toughness, and hardness for temperature applications between -73°C (-100°F) and 649°C (1200°F). It provides greater strength at a good corrosion resistance level.

- CarTech Custom 455® stainless (UNS S45500): This material offers the highest strength at the second level of corrosion resistance. It combines high strength, good corrosion resistance, simple heat treatment, and ease of fabrication.

- CarTech Custom 450® stainless (UNS S45000): This material offers an unusual combination of formability and high strength. Its corrosion resistance is unique for its yield strength. A simple aging process can increase its yield strength by 50% without significantly decreasing corrosion resistance.

For miniature flow control valves, 303 stainless steel allows for easier and more economical shaping of small, intricate valve bodies. 304 stainless steels provide additional corrosion protection for internal working parts. In high-quality stainless steel ball valves, 316 stainless steel is used for the valve body and internal parts due to its excellent corrosion resistance to aggressive gases and chemicals. 304 stainless steel is used for external parts not in continuous contact with aggressive chemicals. The primary distinction between 316 and 316L stainless steel lies in carbon content. 316L has a lower carbon content (0.03% max vs. 0.08% max for 316). This makes it more ductile when annealed and significantly more corrosion resistant, especially after welding. CF8M stainless steel, also known as cast 316, offers excellent corrosion resistance to aggressive gases and chemicals. It also provides the option for intricate cast valve bodies, reducing machining costs. 15-7 stainless steel is noted for its high strength, hardness, and good corrosion resistance. It is particularly useful for applications requiring high strength at high temperatures.

Here is a summary of common stainless steel grades and their applications in control valves:

| Grade | Key Properties | Application in Control Valves |

|---|---|---|

| 201 | Low cost, poor corrosion resistance, high hardness | Suitable for mild, indoor conditions, e.g., low-pressure clean water or air valves |

| 202 | Moderate corrosion resistance, better than 201 | Used in low corrosive environments, like auxiliary piping or basic food-grade applications |

| 301 | High strength, good corrosion and heat resistance | Often used for springs, valve stems, or medium-pressure steam valve parts |

| 304 | Excellent general-purpose corrosion resistance | Common in chemical, food, pharmaceutical, and gas valve components |

| 316 | Superior corrosion resistance, especially in chloride-rich environments | Ideal for marine, desalination, acid handling, and other harsh environments |

Nickel Alloys for Control Valves: High-Performance Solutions

Nickel alloys represent high-performance solutions for control valves operating in extremely aggressive environments. These alloys offer superior resistance where stainless steels may fall short.

Key characteristics of nickel alloys include:

- Strength and Toughness: They exhibit exceptional strength and toughness. This allows them to absorb impact without fracturing. They suit applications with high stresses and dynamic loading.

- Corrosion Resistance: Nickel alloys excel in resisting corrosion from harsh chemicals, seawater, and oxidizing environments. They form a protective oxide layer.

- Thermal Stability: They possess remarkable thermal stability. They maintain strength and structural integrity at elevated temperatures.

- Fatigue Resistance: These alloys demonstrate superior fatigue resistance. They withstand repeated stress cycles without failure.

- Creep Resistance: They exhibit exceptional creep resistance. This makes them suitable for applications with sustained high temperatures and loads.

Industries widely use nickel alloys in high-performance control valve solutions:

- Chemical Processing: Manufacturers use them in reactors, pumps, and valves due to their resistance to harsh chemicals.

- Oil & Gas: They are employed in drilling equipment and pipelines. They offer strength and resistance to extreme pressure and corrosive environments.

Exotic Metals for Control Valves: Titanium, Zirconium, Tantalum

Exotic metals like titanium, zirconium, and tantalum offer unparalleled corrosion resistance for the most demanding control valve applications.

Titanium possesses a high strength-to-weight ratio. It is a strong metal with low density. It is ductile, especially in oxygen-free environments, and has a lustrous, metallic-white color. Its high melting point exceeds 1,649 °C (3,000 °F). Commercial grades have an ultimate tensile strength of about 63,000 psi (434 MPa). This makes it 45% lighter than steel with similar strength. It is 60% denser than aluminum but more than twice as strong as 6061-T6 aluminum alloy. Certain alloys, like Beta C, achieve over 200,000 psi (1380 MPa) tensile strength. Titanium loses strength above 430 °C (800 °F). It is fairly hard, non-magnetic, and a poor conductor of heat and electricity. It is a dimorphic allotrope, with a hexagonal alpha form changing to a body-centered cubic beta form at 882 °C (1,619 °F).

Titanium finds use in various valve configurations:

- Ball, Butterfly, Cast, Check, Control, Cryogenic, Custom made, Foot, Forged, Gate, Globe, Needle, Plug, Safety relief, and Strainers.

- It is stocked and supplied as industrial gate, globe, check, ball, butterfly, plug, needle, and custom-made valves.

- It is used in the aerospace industry for regulating valves, stop valves, check valves, needle valves, plug valves, ball valves, and butterfly valves in aircraft pipelines. Common titanium materials include pure titanium and titanium alloy Ti-6Al-4V.

Zirconium also offers excellent corrosion resistance, especially in harsh environments. It has a high specific strength, meaning a low density of 4.51g/cm³ but high strength. It can withstand greater loads and remains lightweight. It exhibits good heat resistance, stable at 600℃ or higher, and excellent low-temperature resistance, avoiding cold brittleness. Zirconium also has excellent anti-damping performance, reducing vibration and noise. It is non-magnetic and non-toxic.

Industries use zirconium in key equipment for efficient and stable production:

- Petrochemical industry: Crude oil extraction, refining, strong acid/alkali production (e.g., sulfuric acid, hydrochloric acid, nitric acid, caustic soda).

- Aerospace field: Fluid control components in hydraulic systems, ground support equipment.

- Marine engineering: Ship piping systems, seawater desalination, ballast water systems, offshore platforms, submarine pipelines.

- Chlor-alkali industry: Controlling chlorine flow in electrolytic cell outlet pipelines.

Tantalum is often used as a surface layer treatment (Tantaline®) for valves. Manufacturers apply this treatment via a proprietary Chemical Vapor Deposition (CVD) process. This treatment provides superior corrosion and pitting resistance for extended service life in chlorinated compounds, hot acids, and other aggressive chemicals. It offers an economical alternative to valves made from exotic alloys like Hastelloy®, Inconel®, Zirconium, and Titanium, with shorter lead times. The robust, metallurgically bonded tantalum layer can withstand high pressure and erosion corrosion.

Limitations of Metallic Control Valve Materials

Even with advanced metallic materials, inherent limitations exist in extremely aggressive corrosive environments. Different substances and conditions affect materials in distinct ways. For example, low concentrations of sulfuric acid can corrode steel, while high concentrations might create a protective film. Hydrogen only corrodes steel under high temperatures and pressure. Chlorine, while not very corrosive when dry, becomes highly corrosive in humid conditions. This highlights that selecting the right material involves considering factors like pressure, temperature, and specific chemical interactions, not just general corrosion prevention.

Metallic materials can suffer from various forms of corrosion:

- Uniform corrosion: This involves consistent deterioration over the entire surface. It is predictable but still results in material loss.

- Galvanic corrosion: This occurs when different bare metal surfaces contact an electrolytic medium, leading to material transfer.

- Pitting corrosion: This is a localized effect, often following damage to a protective layer. It creates irregular pits.

- Stress corrosion cracking: This results from a combination of mechanical stress and corrosion, leading to fracturing.

- Intergranular corrosion: This involves the degradation of metal around grain boundaries. It is common in stainless steel castings or welds.

- Crevice corrosion: This arises from stagnant fluid in confined areas. It is particularly problematic with intermittent use.

- Microbiologically influenced corrosion (MIC): Microorganisms cause this by producing corrosive by-products, especially in untreated water systems.

Even materials like stainless steel, while offering better resistance than cast iron or carbon steel, can experience accelerated corrosion. This happens if abrasive particles damage their passive, protective layer. For extremely aggressive environments, stainless steel may not be sufficient. This necessitates the use of superalloys or non-metallic materials. The inherent limitations of metallic alloys include thresholds for concentration, temperature, and specific chemical interactions. Beyond these thresholds, they will corrode. Mechanical damage or specific chemical conditions can also compromise their protective layers.

Non-Metallic Control Valve Materials for Corrosive Service

Non-metallic materials offer compelling alternatives to metals in many corrosive control valve applications. These materials often provide superior chemical resistance, especially against acids, alkalis, and salts, where metallic options might struggle. Their use can lead to extended service life and reduced maintenance in specific environments.

Engineering Plastics for Control Valves: PTFE, PEEK, PVDF

Engineering plastics like Polytetrafluoroethylene (PTFE), Polyether Ether Ketone (PEEK), and Polyvinylidene Fluoride (PVDF) are crucial for control valve components in highly corrosive environments. These materials offer exceptional chemical resistance and specific temperature capabilities.

PTFE, commonly known as Teflon, exhibits remarkable chemical stability. It reacts almost none with chemicals and resists corrosive liquids such as strong acids and alkalis. Its inertness comes from strong carbon-fluorine bonds. PTFE also shows excellent resistance to fluctuating high and low temperatures.

| Material | Chemical Compatibility | Operating Temperature Range |

|---|---|---|

| PTFE | Works well with a wide range of media, except fluorine and liquid alkalis. | -429°F to 400°F (Note: Temperature performance is highly dependent on operating pressure). |

| PEEK | Good chemical compatibility. | -70°F to 600°F. |

Another table further details the properties:

| Material | Chemical Resistance | Temperature Range (Continuous) | Peak Temperature (Short-term) |

|---|---|---|---|

| PTFE | Chemically stable, reacts almost none with chemicals, resistant to corrosive liquids (strong acids, alkalis). Inert due to carbon-fluorine bonds. | -200 to 260°C (-328 to 500°F) | 260 to 300°C for 2 hours |

| PVDF | Slightly inferior to PTFE but still among the best. Resistant to acids, alkalis, and organic solvents. Not resistant to certain strong oxidizing acids. Strong antioxidant properties. | -40 to 150°C (-40 to 302°F) | 180°C for 1 hour |

PEEK offers excellent chemical resistance and high-temperature tenacity, resisting extremely high temperatures up to 250°C. However, sulfuric acid can affect PEEK. PVDF, while slightly less resistant than PTFE, still ranks among the best for chemical resistance. It resists acids, alkalis, and organic solvents, possessing strong antioxidant properties.

| Material | Chemical Resistance | Temperature Resistance |

|---|---|---|

| PTFE | Great chemical resistance; will not react with other chemicals. | Excellent resistance to fluctuating high and low temperatures. |

| PEEK | Excellent chemical resistance; will not react with other chemicals. Affected by Sulphuric acid. | High-temperature tenacity; can resist extremely high temperatures (up to 250°C). |

A final comparison of operating temperatures:

| Material | Operating Temperature (°C) | Chemical Resistance |

|---|---|---|

| PTFE | 260 | Excellent |

| PEEK | 300 | Good |

| PVDF | 8.5 (Note: This value seems inconsistent with other sources for continuous operating temperature, but is listed here for comparison) | Good |

Elastomers for Control Valves: Seals and Linings

Elastomers play a vital role in control valve applications, primarily serving as seals, O-rings, and linings. Their flexibility and resilience provide excellent sealing capabilities, preventing leakage of corrosive media. Common elastomers include EPDM, Viton, Buna-N, and Kalrez, each offering specific chemical resistance and temperature ranges. EPDM resists many acids, alkalis, and steam, making it suitable for water treatment and chemical processing. Viton excels in hydrocarbon and high-temperature applications. Buna-N provides good resistance to oils and fuels. Kalrez, a perfluoroelastomer, offers the broadest chemical resistance, often approaching that of PTFE, for the most aggressive environments. Manufacturers frequently use elastomeric linings to protect metallic valve bodies from direct contact with corrosive fluids, extending the valve’s lifespan.

Composites for Control Valves: Strength and Chemical Resistance

Composite materials combine different substances to achieve enhanced properties, offering superior strength and chemical resistance for control valve components. These materials overcome limitations of traditional metals and plastics.

- Metal Matrix Composites (MMCs) combine the strength and toughness of metals with the corrosion and wear resistance of ceramic reinforcements.

- Aluminum matrix composites with silicon carbide particles offer excellent corrosion resistance and lightweight properties. These are ideal for electric control valve applications where weight reduction is crucial.

- Nickel-based MMCs provide outstanding performance in high-temperature corrosive environments. They combine nickel alloy corrosion resistance with enhanced wear resistance from ceramic reinforcements.

- These materials are particularly effective for valve trim components in severe conditions like coal gasification and petrochemical applications.

Polyphenylene Sulfide (PPS) is another high-performance, fiber-reinforced, advanced composite. This linear thermoplastic polymer offers superior corrosion resistance compared to stainless steel. Its stable molecular structure, where benzene rings connect to sulfur atoms in polymer chains, contributes to this resistance. The extremely stable carbon-sulfur bonds in PPS make it difficult for other compounds to penetrate and cause corrosion, even at elevated temperatures. PPS has a high strength-to-weight ratio. It has replaced conventional materials like stainless steel in industrial applications requiring superior corrosion resistance and high-temperature performance. Unlike stainless steel, which deals with corrosion on a macroscopic level (porous granular alloy), PPS addresses corrosion on a microscopic level with its tight repeating molecular crystalline structure.

Advantages and Disadvantages of Non-Metallic Control Valve Materials

Non-metallic materials offer distinct advantages and disadvantages compared to their metallic counterparts in control valve applications. Understanding these helps in proper material selection.

Advantages of Non-Metallic Materials:

- Superior sealing performance often achieves zero leakage. This makes them ideal for high fluid containment, such as potable water and gas pipelines.

- Lower operating torque requires less force for actuation.

- Reduced maintenance needs occur in low-temperature, non-abrasive environments.

- Corrosion resistance comes from non-metallic seating material, especially in aggressive fluid environments.

- Excellent sealing achieves bubble-tight shut-off (e.g., ANSI Class VI) due to the elastic deformation of soft materials.

- Low sealing torque is required, making operation easier.

- Some tolerance for particulates exists, as small impurities can embed without compromising the seal.

- Lower cost to manufacture and replace.

- Resistance to corrosion from most acids, salts, and alkalis makes them ideal for water, wastewater, and corrosive substances.

- Lightweight properties simplify transportation and installation, reducing strain on supporting structures and lowering installation/maintenance costs.

- Easy handling with generally less expensive installation materials compared to metal valves. This makes them popular for residential plumbing and irrigation.

- Smooth interior surfaces minimize friction, allowing efficient fluid flow and reducing wear and tear.

- They require minimal maintenance due to durability and non-corrosive nature.

Disadvantages of Non-Metallic Materials:

- Limited temperature and pressure range; elastomeric materials degrade beyond 150-200°C (302-392°F).

- Susceptibility to wear and damage from abrasive particles leads to leaks and frequent seat replacements.

- Not fire-safe, making them unsuitable for fire-prone applications like oil refineries and chemical plants.

- Poor temperature resistance generally makes them unsuitable for high temperatures (typically -20°C to 180°C).

- Poor abrasion and erosion resistance means high-velocity fluids or hard particles can damage the soft sealing surface.

- Limited chemical compatibility requires careful selection based on specific media (though PTFE has excellent resistance).

- Aging of elastomeric materials leads to brittleness from UV light or ozone exposure.

- Limited temperature tolerance; PVC becomes brittle and loses strength at extreme temperatures (hot or cold), unsuitable for high heat or sudden temperature fluctuations.

- Lower pressure rating compared to metal valves means they are not designed for high-pressure fluids or gases.

- Not suitable for applications involving flammable or volatile chemicals, as PVC can degrade when exposed to certain solvents or aggressive chemicals.

Utilizing Control Valve Material Compatibility Charts

Selecting the correct material for control valves in corrosive environments requires careful consideration. Material compatibility charts provide essential guidance. These tools help engineers make informed decisions.

How to Interpret Control Valve Compatibility Charts

Interpreting control valve compatibility charts effectively is a crucial skill. First, users must understand the grid structure. They locate valve materials in rows and chemicals or media in columns. The intersection provides the compatibility rating. Second, users must grasp common rating systems. These typically use letters like A-D to quickly assess material suitability. Third, users consider key variables. Chart ratings are baselines, usually at 20°C and atmospheric pressure. Real-world operating conditions, such as media concentration, operating temperature, and system pressure, can significantly alter compatibility. Finally, users treat the chart as a starting point. For critical applications or when in doubt, they perform real-world testing to confirm compatibility.

| Rating | Description |

|---|---|

| A | Excellent: The material is highly resistant to the chemical and is suitable for continuous use. |

| B | Good: The material has good resistance, but some minor effects may occur over time. Suitable for most applications. |

| C | Fair: The material has moderate resistance, and noticeable effects (e.g., swelling, degradation) may occur. May be suitable for intermittent use or less critical applications. |

| D | Poor: The material is not recommended for use with the chemical due to significant degradation or rapid failure. |

| - | Information Not Available: Compatibility data for this specific combination is not readily available. Further testing or expert consultation is recommended. |

Leveraging Manufacturer Data Sheets for Control Valves

Manufacturer data sheets offer detailed information beyond general compatibility charts. These documents provide specific material compositions, mechanical properties, and recommended operating limits for their products. Engineers consult these sheets for precise data on a valve’s body, trim, and sealing materials. This ensures the selected valve meets the exact process requirements.

The Role of Industry Standards in Control Valve Material Selection

Industry standards play a vital role in control valve material selection. Organizations like ASTM, ASME, and NACE establish guidelines for material specifications, testing procedures, and performance criteria. Adhering to these standards ensures material quality, reliability, and safety. They provide a common framework for manufacturers and users, promoting consistency and reducing risks in corrosive service applications.

Coatings, Linings, and Surface Treatments for Control Valves

Control valves often operate in harsh environments. Coatings, linings, and surface treatments significantly enhance their protection. These applications extend valve lifespan and improve performance in corrosive services.

Enhancing Control Valve Protection with Coatings

Coatings provide a crucial barrier against corrosive media. Standard Electroless Nickel Plating (ENP) offers a cost-effective solution, particularly effective against chlorides. Teflon coatings resist corrosion due to their plastic nature, preventing adhesion of elements like paraffin wax. However, Teflon has low erosion resistance. Epoxy coatings provide outstanding corrosion resistance, forming a protective barrier against chemicals and moisture. Thermal spray coatings, applied at high temperatures, enhance both corrosion and wear resistance. Polymer coatings offer an exceptional chemical barrier and flexibility. Nickel-based coatings, such as Inconel, deliver remarkable protection against oxidation and corrosion at elevated temperatures. Ceramic coatings excel for valves exposed to abrasive media, resisting erosion and chemical corrosion. Zinc coatings provide galvanic protection, sacrificially corroding instead of the valve material. Belzona 13215, a ceramic-filled epoxy, offers erosion and corrosion resistance with high compressive strength.

Benefits of Internal Linings for Control Valves

Internal linings protect metallic valve bodies from direct contact with corrosive fluids. This extends the valve’s service life. Lined valves offer excellent resistance to chemical attacks. They handle a wide range of temperatures, depending on the lining material. Linings are effective against abrasion and slurries, and their smooth surface facilitates cleaning, extending design life. This results in low maintenance requirements. Perfluoroalkoxy (PFA) lining resists a wide range of corrosive media and extreme temperatures. Polytetrafluoroethylene (PTFE) lining offers exceptional chemical resistance to strong acids and bases. TFM, a second-generation PTFE, handles higher temperatures and pressures with less deformation. Rubber linings, like Neoprene or EPDM, protect against abrasion and corrosion, ideal for abrasive slurries.

Advanced Surface Treatment Technologies for Control Valves

Advanced surface treatment technologies improve the durability and chemical resistance of control valve materials. Fluoropolymer coatings, including PTFE and PFA, enhance chemical resistance against corrosive substances. Ceramic coatings increase chemical and wear resistance, offering superior hardness for aggressive chemicals and high temperatures. Composite coatings combine multiple materials, balancing chemical resistance with other properties. Surface treatment techniques like plasma treatment or chemical etching improve coating adhesion. Robert Bosch GmbH uses a multi-layer approach with a nickel-phosphorus alloy base, a ceramic layer, and a fluoropolymer topcoat. Parker-Hannifin Corp. employs a “ChemShield” system, combining electroless nickel plating with a specialized polymer overlay. High-Velocity Oxygen Fuel (HVOF) coatings, particularly chrome carbide, are utilized for severe service valves. This thermal spray process creates dense, durable coatings, significantly enhancing performance and longevity.

Economic Considerations for Control Valve Material Selection

Balancing Initial Cost with Lifecycle Cost for Control Valves

Selecting control valve materials involves balancing initial purchase price with long-term operational expenses. High-quality materials, such as stainless steel, titanium, or specialized alloys, typically have higher upfront costs. However, their superior durability, corrosion resistance, and performance in extreme conditions often lead to reduced maintenance needs and extended service life. Conversely, less expensive materials like cast iron or basic carbon steel offer lower initial costs but may require more frequent replacement or maintenance, significantly increasing long-term operational expenses. Manufacturers quantify the complete lifecycle cost of a valve design to mitigate risk, especially with increasing price sensitivity. The Total Cost of Ownership (TCO) is crucial for repair-versus-replacement decisions. For critical valves, if repair costs exceed 60-65% of a new valve’s price, replacement often becomes the more economical choice.

Impact of Downtime and Maintenance on Control Valve Costs

Control valve downtime and maintenance significantly impact overall operational costs. Unplanned outages lead to substantial financial losses.

- Lost revenue and production represent a direct expense, with high-throughput operations potentially losing thousands of dollars per hour.

- Emergency labor and overtime increase costs as unplanned downtime necessitates premium rates and external expert travel.

- Wasted materials and energy occur when stopping a process, often requiring scrapping materials in the line. Restarting complex systems consumes significantly more energy than steady-state operation.

For example, a herbicide plant reduced annual maintenance costs by $230,000 by transitioning to predictive maintenance. This plant also saved nearly $100,000 per hour by proactively addressing a control valve issue.

Long-Term Investment vs. Short-Term Savings in Control Valves

Investing in high-quality control valve materials, despite higher initial costs, yields significant long-term financial benefits. The performance and longevity of a valve critically depend on selecting appropriate materials for parts contacting the process fluid. This choice balances chemical compatibility, temperature resistance, and cost. For instance, using Stainless Steel (304 or 316) offers excellent corrosion resistance for chemical, food, and pharmaceutical applications. Exotic alloys like Duplex, Super Duplex, or Titanium are specified for highly corrosive environments. Upgrading disc materials, such as fitting a ductile iron body with a stainless steel disc, enhances longevity. Similarly, selecting the right seat material, like Viton for broad chemical resistance or PTFE for aggressive chemicals, ensures a leak-tight seal and extends the valve’s service life. These material selections contribute to greater reliability, fewer potential failure points, and easier maintenance, ultimately reducing downtime and maintenance labor costs over the valve’s operational life, thereby lowering the total cost of ownership.

Common Mistakes in Control Valve Material Selection

Overlooking Specific Process Conditions for Control Valves

Engineers often make critical errors by overlooking specific process conditions during control valve material selection. This oversight leads to premature valve failure and operational inefficiencies. For instance, selecting a valve without considering fluid properties like viscosity and corrosivity can result in poor performance and accelerated corrosion.

- Underestimating fluid properties means choosing materials unable to withstand specified fluid characteristics.

- Failing to consider temperature and pressure variations causes valve deformation or catastrophic failure. Valves must operate across the full range of expected conditions.

- Using valve materials incompatible with the process fluid leads to corrosion, leakage, and premature failure. Engineers must select materials resistant to specific chemicals and conditions.

- Ignoring system dynamics, such as changes in flow direction, velocity, and turbulence, results in improper valve selection and performance problems.

Thoroughly understanding the application, including fluid type, temperature, pressure, flow rate, and environment, is crucial. Misjudging these parameters can lead to valve failure or inefficiency.

Relying Solely on Generic Data for Control Valves

Relying solely on generic material data for control valve applications presents significant risks. This approach often leads to material incompatibility, where a material cannot resist chemical attack, degradation, or corrosion from the process fluid. Such incompatibility causes several issues:

- Increased downtime: Components age or fatigue more quickly, leading to frequent breakdowns and higher maintenance expenses.

- Decreased reliability: Components weaken and fail over time, diminishing valve reliability and increasing failure risk.

- Leakage: Aging or fatigued components can cause leaks, resulting in process fluid loss and potential environmental harm.

- Decreased safety: Worn-out or degraded components heighten the risk of valve failure, which can have significant safety implications.

Valves must use materials compatible with the substances they handle to prevent corrosion, contamination, or other hazards. Identifying the chemical composition of the process fluid, including potential impurities, and determining operating temperature and pressure are crucial steps.

Neglecting Future Process Changes for Control Valves

Neglecting future process changes represents a significant oversight in control valve material selection. This can lead to premature failure and costly modifications. While engineers often dedicate considerable time to specifying valves for current operating conditions, they frequently overlook undefined variations. These variations include future capacity changes, product variations, and operational shifts. Such omissions result in system problems requiring detailed analysis and potentially leading to production shutdowns.

To anticipate and account for future process changes, specifying a control valve with multiple internal, replaceable control components is crucial. This allows the valve to accommodate both current and future applications. For example, a South American copper mine successfully implemented this strategy. They selected a rotary control valve with four interchangeable flow capacity ranges. This enabled them to install a common 2-inch rotary control valve body and simply change the valve seat when an increase in flow capacity was needed. This approach avoided costly and labor-intensive piping modifications.

Meticulous material selection for control valves is critically important. This decision directly impacts operational safety and efficiency. Proper material choices ensure control valve longevity, offering significant long-term benefits and reducing overall costs. Always consult with material specialists and control valve manufacturers. This guarantees optimal performance and reliability in corrosive environments.

FAQ

What is the most critical factor in selecting control valve materials?

The most critical factor is chemical compatibility. Materials must resist the process fluid’s corrosive effects. This ensures reliable operation and prevents premature failure.

Why are non-metallic materials sometimes preferred over metallic ones?

Non-metallic materials offer superior chemical resistance to many acids, alkalis, and salts. They often provide excellent sealing and can be lighter. This extends service life in specific corrosive environments.

How do temperature and concentration affect material choice?

Elevated temperatures reduce material strength and accelerate corrosion. Higher concentrations of corrosive media demand more robust materials. Both factors significantly influence a material’s integrity and lifespan.

Post time: Dec-18-2025