I distinguish the primary goals of flow control valves and pressure control valves. Pressure control valves regulate fluid pressure, maintaining safe operating limits and preventing system problems. Conversely, flow control valves manage flow rates, directly influencing actuator speed and the rate of energy transfer. Each Control Valve type serves a distinct purpose for optimal system performance.

Key Takeaways

- Flow control valves manage how much fluid moves. They control the speed of a process. Pressure control valves keep the fluid pressure steady. They prevent system damage.

- Choose a flow control valve when you need to control fluid speed or volume. Pick a pressure control valve when you need to keep pressure stable and safe.

- Always match the valve type to your system’s main goal. This helps your system work well and prevents problems.

Understanding Flow Control Valves

Defining a Flow Control Valve

I define a flow control valve as a crucial component in fluid systems. Its primary function is to regulate the amount of liquid or gas moving through a pipeline. These devices modify the rate of fluid flow in a hydraulic circuit. They achieve flow variability by adjusting the effective orifice size inside the valve. This regulation ensures equipment operates safely and efficiently. Controlling the flow rate is essential for the operation of fluid-powered machines or actuators.

How Flow Control Valves Operate

Flow control valves operate by changing the flow passage inside the valve. This adjustment impacts other fluid process parameters like temperature and pressure. For instance, a needle valve uses a needle-like plunger. It adjusts its position to restrict or allow fluid flow. Partially closing the valve reduces the space for fluid, decreasing the flow rate. A ball valve employs a spherical ball with a central bore. Rotating the ball controls flow. Aligning it with the pipeline allows free flow. Positioning it perpendicular restricts it. Some valves also respond to pressure changes. They open or close based on rising pressure to relieve or reduce it.

Common Flow Control Valve Types

I see several common types of flow control valves in industrial applications. Ball valves use a spherical plug design. They offer excellent control of liquid flow and secure shutoff. Butterfly valves are lightweight and easy to operate. They are common in oil and gas processing. Globe valves are linear motion valves. They stop, start, and regulate flow. They are suitable for both on/off and throttling applications. Gate valves are primarily for on/off service. They allow straight-line fluid flow with minimal restriction. Needle valves offer precise control of flow. They feature a sharp pointed disc and a matching seat.

Typical Applications for Flow Control Valves

Flow control valves are essential across many industries. In oil and gas, they regulate flow, pressure, and temperature. They ensure safety and efficiency in pipeline operations. Water treatment plants use them to control water flow and distribution. They also manage filtration processes. Chemical processing relies on them to regulate corrosive and hazardous chemicals. This ensures precise mixing. In food and beverage, they control liquid and gas flow during processing. They maintain hygiene standards. Manufacturing uses these valves to control coolants and hydraulic fluids. This automates industrial processes. A Control Valve is vital for precise material handling.

Understanding Pressure Control Valves

Defining a Pressure Control Valve

I define a pressure control valve (PCV) as a vital device in industrial settings. It prevents pressure vessels from becoming over-pressurized. Its main job is to release pressure when necessary. This can involve gas, steam, liquids, or vapors. I see these valves as essential for system safety.

How Pressure Control Valves Operate

Pressure control valves operate to maintain or reduce system pressure. Pressure Reducing Valves (PRVs) balance the force between a spring and the downstream pressure. I set the desired pressure by adjusting the spring’s tension. If downstream pressure gets too high, the diaphragm pushes the spring. This reduces the valve opening and lowers the pressure. These valves often use a load (like a spring), a sensor (diaphragm or piston), and a poppet. The poppet adjusts to differences between the load and fluid pressure. Pressure reducing regulators automatically lower high inlet pressure to a stable outlet pressure. They use mechanical feedback loops.

Common Pressure Control Valve Types

I encounter several common types of pressure control valves. Relief valves automatically release pressure when system limits are exceeded. They prevent damage by diverting excess fluid. Pressure reducing valves maintain a lower, consistent downstream pressure. They restrict flow to reach a set point. Sequence valves allow flow to a secondary circuit only after a specific pressure is met in the primary circuit. Counterbalance valves, also known as load-holding valves, ensure controlled movement in hydraulic systems. They prevent loads from running away.

Typical Applications for Pressure Control Valves

Pressure control valves are crucial across many industries. They maintain optimal pressure levels within systems. I find them essential for controlling gas and liquid pressure. This ensures safe and efficient operations. They prevent equipment damage and reduce leak risks. You will see them in chemical processing, water treatment facilities, and the oil and gas industry. They are also vital in pharmaceutical production and manufacturing plants. These valves are key for general hydraulic and pneumatic systems.

Flow vs. Pressure Control: A Direct Comparison

Key Operational Differences

I see distinct operational differences between flow control valves and pressure control valves. A flow control valve primarily manipulates the volume of fluid passing through a system over time. It directly influences how quickly a process occurs or how fast an actuator moves. I adjust its opening to achieve a desired flow rate. Conversely, a pressure control valve focuses on maintaining a specific pressure level within a system. It reacts to pressure changes, opening or closing to relieve excess pressure or to ensure a minimum pressure is met. I find that flow control valves are about speed and volume, while pressure control valves are about stability and safety.

Impact on System Performance

The choice between a pressure control valve and a flow control valve significantly impacts overall system performance. I have observed these differences firsthand:

| Feature | Pressure Control Valve (PCV) | Flow Control Valve (FCV) |

|---|---|---|

| Function | Regulates pressure, keeps it constant | Adjusts flow rate, controls speed of fluid/gas |

| Impact on System | Pressure remains steady, flow may vary | Flow is steady, pressure may fluctuate |

I find that a Pressure Control Valve (PCV) ensures pressure remains stable. This prevents equipment damage and ensures stable operation. However, the flow rate may vary with a PCV. On the other hand, a Flow Control Valve (FCV) regulates the flow rate. This optimizes process speed and enhances overall system efficiency. It maintains a desired volume of fluid or gas. With an FCV, flow is steady, but pressure may fluctuate.

I always assess system pressure requirements. If pressure stability is paramount to prevent equipment damage, a PCV is essential. If maintaining a steady flow rate is more critical for operational efficiency, an FCV is the better choice. I also consider the type of fluid or gas. For high-pressure gases where stable pressure is crucial, a PCV is ideal. For precise control over fluid flow and consistent flow rates, an FCV is preferred. For systems requiring both pressure stability and flow consistency, I often consider using a combination of pressure and flow control valves.

When to Prioritize Flow Control

I prioritize flow control when the rate of fluid movement is the most critical aspect of my system’s operation. This often happens in scenarios where:

- Rapid response is prioritized over precise throttling control. I see this with quick opening valves.

- Safety shutdown systems require immediate flow interruption or rapid flow establishment.

- Two-position control applications need reliable switching between fully open and fully closed positions. They do not require precise throttling.

- Startup and batch process applications require initial system charging or rapid process changes. This reduces startup times and improves efficiency.

I also prioritize flow control when precise adjustments to flow rates are required. This is different from simple on/off functionality. The opening action of the valve needs a predictable relationship with the variation of flow allowed through it. Meticulous control of flow rates is necessary in many applications. I often use needle valves or V-ball valves for this purpose.

When to Prioritize Pressure Control

I prioritize pressure control when maintaining a stable and safe pressure within the system is paramount. This is crucial for protecting equipment and ensuring consistent operation. For example, I always use pressure control valves to prevent over-pressurization in pipelines and vessels. This safeguards against leaks and catastrophic failures. In hydraulic systems, I rely on pressure control to ensure actuators operate within their design limits. This prevents damage and extends their lifespan. I also use pressure control to maintain a consistent supply pressure to downstream components. This ensures their optimal performance. When system integrity and safety depend on pressure stability, a pressure control valve is my primary choice.

Selecting the Right Control Valve

Defining Your System’s Primary Goal

I always begin the selection process by clearly defining my system’s primary goal. This initial step is crucial for making informed decisions. I first gather detailed information about the fluid type, flow rates, temperature, and pressure conditions. I also consider any specific process needs. This helps me understand the overall process requirements. Next, I determine the Flow Coefficient (Cv). This parameter tells me the valve’s capacity to pass a specific flow rate under a given pressure drop. I then select the valve type based on the application, fluid characteristics, and the desired control action. I evaluate the valve’s inherent flow characteristics, such as linear, equal percentage, or quick opening, to see how the flow rate changes with valve position. I also check the valve’s rangeability. This ensures the valve can effectively handle the required flow range. I perform sizing calculations using Cv, process parameters, and valve characteristics. Finally, I verify these calculations with the manufacturer’s specifications for compatibility.

I also consider potential pitfalls early on. I avoid ignoring system dynamics, which can lead to improper valve selection. I never underestimate fluid properties like viscosity and corrosion. This prevents poor performance and accelerated corrosion. Material compatibility is always crucial. I accurately calculate pressure drop to prevent issues like cavitation. I also consider future system expansions. This ensures the chosen valve accommodates both current and future requirements. I pay close attention to specific valve requirements and sizing considerations. I ensure the valve operates effectively across the full range of expected temperature and pressure conditions. I avoid selecting incompatible valve materials. This prevents corrosion, leakage, and premature failure. I also make sure to estimate flow rates correctly. Incorrect estimates lead to inefficiencies and equipment failure. I consider gas properties for compatibility. This prevents material degradation and safety risks. I never ignore the pressure differential. This prevents inadequate flow and safety hazards. Finally, I do not disregard maintenance. Neglecting routine inspections reduces a valve’s lifespan.

Considering Fluid Characteristics

When I select a valve, I pay close attention to the fluid’s characteristics. These properties significantly influence my choice. Viscosity, for example, affects pressure drop and how responsive the valve is to actuator inputs. It also impacts trim wear rates and pump efficiency. I know that viscosity is temperature-dependent; as temperature increases, liquid viscosity rapidly decreases. This means I must determine viscosity values over the entire operating temperature range. This ensures precise control valve tuning. The viscosity index is also crucial for fluids whose viscosity fluctuates with temperature. These fluids require robust sealing materials and valves that retain responsiveness.

Highly viscous fluids and slurries need minimal pressure drop across the valve body. This prevents plugging. I find globe valves, which induce significant pressure drops, unsuitable for highly viscous fluids. Ball valves, however, generate minimal pressure drops. I regularly use them for these applications.

Corrosive fluids also necessitate specific valve materials. I often choose valves made from special alloys or with protective linings to prevent degradation. Highly viscous fluids demand valves designed to handle increased resistance to flow. Temperature sensitivity is another factor. Some fluids change state or properties with temperature variations. This directly affects valve performance. For instance, I use stainless steel for chemical, food, beverage, and pharmaceutical applications due to its corrosion resistance. Brass works well for water, oil, and air lines. It offers durability and resistance to non-aggressive fluids. Carbon steel is my choice for high-pressure and high-temperature applications in oil and gas or power generation. For lower-pressure water systems, irrigation, and chemical drainage, I often select PVC/CPVC because they are lightweight and corrosion-resistant.

Evaluating Control Precision Needs

I always evaluate the level of control precision my system requires. This directly impacts my valve choice. Different industries and applications have varying precision needs.

| Industry/Application | Control Precision Requirement | Impact on Valve Choice (Examples) |

|---|---|---|

| Chemical Processing (Reaction Control) | Precise control of flow, temperature, pressure | Valves for optimal reaction conditions, corrosion-resistant materials |

| Oil and Gas (Pipeline Flow Management) | Modulate flow and pressure | Valves for safe transport, reliable on/off control (e.g., ball/plug valves) for isolation |

| Water and Wastewater Treatment (Flow Regulation, Mixing) | Consistent pressure and flow rates, precise chemical dosing | Valves for proper filtration/disinfection, accurate chemical mixing |

| Food, Beverage, and Pharmaceuticals (Dosing) | High accuracy for ingredient/chemical dosing | Valves meeting hygienic standards, preventing contamination |

| Power Generation and HVAC (Steam/Cooling Systems) | Regulate steam flow and coolant circulation | Valves for optimal operating temperatures/pressures, energy efficiency |

| General Process Control | Critical for performance and safety | Selection based on process conditions, fluid properties, control requirements |

| General Process Control | Continuous control (modulating) vs. isolation (on/off) | Modulating valves for continuous control, on/off valves for isolation |

| General Process Control | Specific flow characteristics (equal percentage, linear, quick-opening) | Valves with characteristics matching process dynamics |

| General Process Control | Enhanced control accuracy | Valves with smart positioners or integrated feedback systems |

For applications demanding high performance and precise regulation, I find single-seated control valves ideal. They offer excellent sealing performance and stable operational behavior. Their well-defined flow characteristic curve makes them excel in applications requiring high precision, high flow rates, and minimal pressure drop. They can achieve virtually zero leakage. This ensures process reliability and operational safety. The single plug-and-seat design ensures a tight shut-off. This is critical where leakage must be minimized. I widely use them in industries where precise control over flow rates is critical. These include oil and gas, chemical processing, power generation, water treatment, and HVAC systems. For enhanced control accuracy, I often specify valves with smart positioners or integrated feedback systems.

Assessing the Operational Environment

The operational environment significantly influences my control valve selection. Temperature, for instance, plays a critical role. High temperatures reduce metal strength and increase susceptibility to creep. This lowers the allowable working pressure. Non-metallic components like seals are even more affected. Exceeding their temperature range can cause softening, extrusion, or degradation. This leads to leakage. Conversely, cryogenic temperatures can make materials brittle and cause seals to harden. This also results in leaks. Therefore, I must know the full operating temperature range. This includes cold startup to hot emergency conditions. This dictates the selection of body, trim, seals, gaskets, and packing materials. Manufacturers provide Pressure-Temperature (P-T) rating charts. These charts are critical for defining the maximum allowable working pressure at a given temperature. They ensure the selected valve is safe for all operating conditions.

Hazardous materials, specifically corrosive and abrasive fluids, profoundly influence my control valve selection. Corrosion involves the chemical dissolution of valve materials. Abrasiveness is the mechanical wearing away of surfaces. These two factors often act together. Corrosion weakens surfaces and makes them more vulnerable to abrasive erosion (erosion-corrosion). To select appropriate valves, I need precise information about the fluid’s pH and the presence of corrosive agents. Examples include chlorides and sulfides. I also need to know the nature of solids in slurries. This includes hardness, angularity, concentration, and particle size. For abrasive services, the valve’s internal flow path should be smooth. This minimizes impingement. This often leads me to select specialized valves like pinch valves or ball valves with hardened trim materials over standard globe valves.

Cavitation, a phenomenon related to fluid dynamics within the valve, can induce significant vibration. Cavitation occurs when the pressure within the valve’s vena contracta drops below the liquid’s vapor pressure. This causes vapor bubbles to form. If the downstream pressure recovers above the vapor pressure, these bubbles violently collapse or implode. This implosion generates intense, localized pressure waves, micro-jets, and shockwaves. This leads to severe pitting and erosion of the valve trim and body. Crucially, cavitation also causes high levels of vibration. This can damage the actuator and instrumentation. Anticipating and mitigating cavitation is a core task in my control valve selection. This often requires specialized anti-cavitation valves. These valves manage pressure drops in multiple stages or direct implosions away from critical surfaces.

Cost and Maintenance of Control Valves

When selecting a control valve, I always consider the total cost of ownership (TCO). This includes more than just the initial purchase price. TCO encompasses the initial purchase price (CAPEX), installation costs, and operational costs (OPEX). Operational costs include energy consumption, maintenance and repair (spare parts, labor), and downtime costs from lost production.

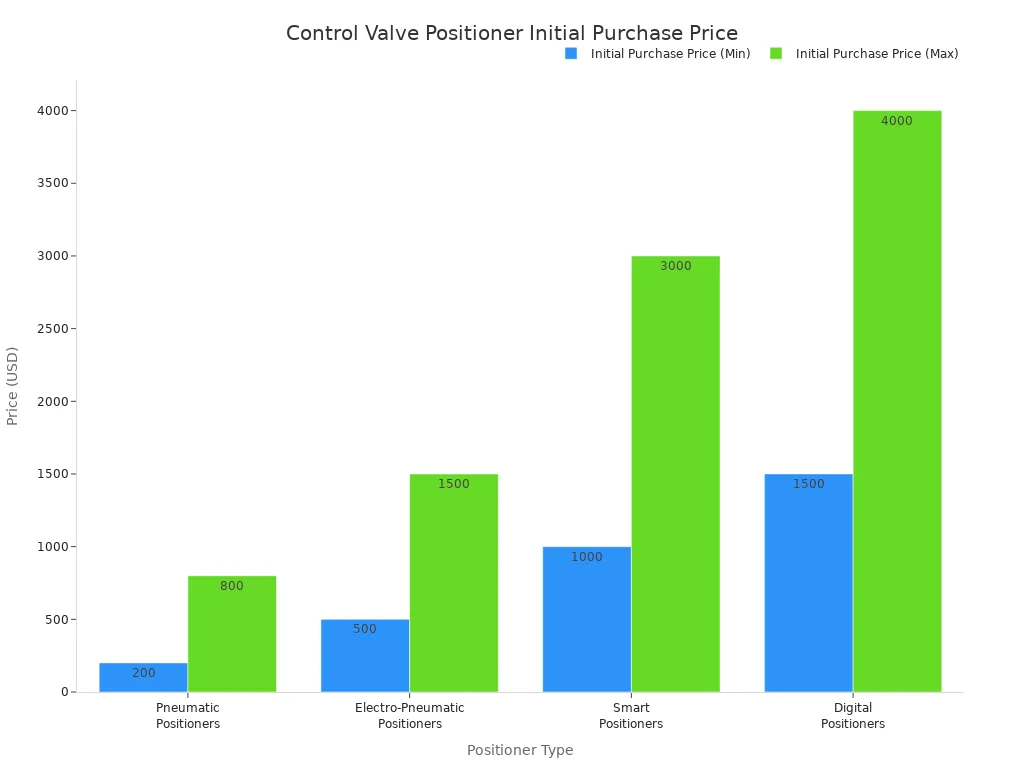

The initial purchase price varies significantly, especially for positioners.

| Positioner Type | Initial Purchase Price (2024) | Maintenance & Long-Term Implications |

|---|---|---|

| Pneumatic Positioners | $200 – $800 | Simple design, fewer components, lower maintenance costs. Less precise, slower response. |

| Electro-Pneumatic Positioners | $500 – $1,500 | More complex than pneumatic, requiring calibration. Offers better precision and integration with control systems. |

| Smart Positioners | $1,000 – $3,000+ | Advanced diagnostics, remote monitoring, predictive maintenance capabilities. Higher initial cost but significant long-term savings through reduced downtime and optimized performance. Requires specialized software and training. |

| Digital Positioners | $1,500 – $4,000+ | Similar to smart positioners but with enhanced digital communication protocols (e.g., HART, Foundation Fieldbus). Offers superior accuracy, control, and data insights. Higher initial investment, but provides the most comprehensive data for process optimization and predictive maintenance. |

I also consider valve design for maintenance. Split-body or end-entry designs often require removal from the pipeline to access internal components. This leads to time-consuming and labor-intensive repairs. It also increases downtime and costs. Top-entry designs, however, allow access to internal parts without removing the valve body from the line. This significantly reduces maintenance time and minimizes process downtime. While their initial cost might be higher, they offer substantial long-term maintenance savings. I always weigh these factors carefully to ensure the best long-term value for my system.

I emphasize aligning the control valve type with system goals. This ensures optimal performance. Correct selection, considering media type and precise sizing, boosts operational efficiency by 20% and reduces safety incidents by 15%. I find this critical for enhanced precision and preventing system failures.

FAQ

What is the main difference between flow and pressure control valves?

I use flow control valves to manage fluid volume. Pressure control valves maintain system pressure. I select each based on my system’s primary goal.

When should I choose a flow control valve?

I choose a flow control valve when process speed or precise volume regulation is my primary concern. This ensures accurate material handling.

Why is fluid viscosity important for valve selection?

Fluid viscosity impacts pressure drop and valve responsiveness. I consider it for proper valve sizing and material selection. This prevents operational issues.

Post time: Dec-18-2025