Balance valves ensure stable, efficient, and safe hydraulic circuit operation. They precisely control pressure and flow. These valves prevent cavitation. They also manage load-induced pressure fluctuations throughout the system’s lifecycle. A Balance Valve is critical for optimal performance.

Key Takeaways

- Balance valves are very important in hydraulic systems. They make sure the system works well and safely. They control how liquids move and stop heavy things from falling too fast.

- Choosing and putting in balance valves correctly is key. Engineers must pick the right valve for the job. They must also set it up properly to make the system work its best.

- Checking and taking care of balance valves regularly helps them last longer. This stops problems and keeps the hydraulic system running smoothly and safely over time.

Understanding Hydraulic Circuit Performance and Its Challenges

Defining Optimal Hydraulic Performance

Optimal hydraulic performance signifies a system’s ability to operate with maximum efficiency, reliability, and precision. It means the system delivers the required power and motion consistently, without excessive energy loss or unexpected downtime. An optimally performing circuit maintains stable pressure and flow, responds accurately to commands, and operates safely within its design parameters. This level of performance ensures longevity for components and minimizes operational costs.

Common Challenges in Hydraulic Circuits

Hydraulic circuits frequently encounter several challenges that hinder optimal performance. One major issue is contamination. Dirt, water, and metal particles often enter the system through maintenance, worn seals, or poor filtration. This causes abrasive wear, corrosion, and reduced efficiency. Another significant problem involves fluid issues. Using the wrong hydraulic fluid results in inadequate lubrication, increased wear, and compatibility problems. Low fluid levels also reduce efficiency and increase wear.

Temperature problems pose a serious threat. Systems can overheat or freeze. High temperatures degrade fluid, reduce lubrication, and increase component wear. Conversely, cold temperatures thicken fluid, forcing the pump to work harder. Fluid leaks are also common. Worn seals, loose fittings, or damaged hoses cause leaks, reducing efficiency and posing safety risks.

Aeration and cavitation represent critical challenges. Air bubbles (aeration) or vapor bubbles (cavitation) in the fluid lead to noise, reduced efficiency, and component damage. Cavitation often manifests as a high-pitched whining or screeching noise from the hydraulic system. Operators might also notice sluggish or inconsistent machine performance, with the system feeling underpowered or slow to respond. The hydraulic system may run hotter than usual, and the fluid might show signs of distress, such as a burnt smell or cloudy appearance. These issues highlight the importance of proper system design and maintenance.

The Fundamental Role of Balance Valves

What is a Balance Valve?

A balance valve is a crucial component within hydraulic circuits. It primarily functions as a load-holding brake, maintaining precise control over a load as it moves. This valve prevents “over-center” loads from causing a cylinder to over-speed the pump. It opens only enough to allow the load to move at a desired flow rate. This action prevents the load from “running away” due to external forces like gravity. Unlike simpler pilot-operated check valves, a balance valve can meter oil flow for controlled lowering. It ensures hydraulic actuators can lift and lower heavy objects at a constant speed. The valve uses precise throttling and pressure compensation. This allows loads to hover and position accurately at any point, preventing accidental downward sliding.

How Balance Valves Enhance Hydraulic Performance

Balance valves significantly enhance hydraulic performance by ensuring stability, safety, and efficiency. They enable continuous piston operation and minimize movement errors of the piston rod, even with dynamic loads. This allows for precise control of the piston stroke within a defined range, ensuring safe and reliable operation.

Balance valves also manage the deceleration and positioning of the piston rod. This ensures safe and dependable work. They guarantee efficient fluid flow by addressing unstable internal fluid pressure. The valves control piston stroke pressure within a narrow range, leading to stable and efficient operation. They regulate fluid flow and pressure to achieve energy savings.

Furthermore, balance valves provide critical safety and control features:

- Dynamic Load Control: They prevent uncontrolled acceleration of loads during descent. The valve dynamically adjusts throttling based on real-time pressure and flow changes. This restricts downward speed within safe limits, ensuring stable and controllable movement. This remains true even with sudden load changes or system disturbances. If the load begins to “run away,” the valve adjusts to match the cylinder speed to the pump flow, preventing uncontrolled movement.

- Emergency Safety Protection: A balance valve activates a built-in safety locking function in extreme situations, such as pipeline bursts. It cuts off the load oil circuit and locks the actuator in its current position. This mechanism prevents load dropping accidents caused by hydraulic failure, providing a critical safety measure.

- Flow Regulation: Counterbalance valves regulate fluid flow by allowing free flow into the actuator to lift a load. They block reverse flow until a preset pressure is reached. This preset pressure is higher than the system pressure when the load applies. This allows fluid to flow in the opposite direction, enabling actuator function.

Design Considerations for Integrating Balance Valves

Careful design ensures optimal hydraulic system performance. Integrating balance valves requires thoughtful consideration. Engineers must select the correct valve type. They must also determine its placement and set its pressure accurately. These steps are crucial for system efficiency, safety, and longevity.

Early Stage Design: Balance Valve Selection Criteria

Selecting the appropriate balance valve is a critical first step. Designers must consider several factors. These factors ensure the valve meets the specific demands of the hydraulic application.

- Maximum Load: Determine the maximum load the valve must hold. This helps select a valve with an appropriate pressure rating.

- Required Flow Rate: Ensure the valve’s flow capacity handles the maximum flow. This prevents excessive pressure drop.

- Pilot Ratio: Consider the pilot ratio. A lower ratio needs higher pilot pressure to open. A higher ratio requires less.

- Mounting Style and Port Sizes: These must be compatible with the existing hydraulic system.

- Specific Requirements: Account for needs like integrated free-flow check or overload protection.

- System Operating Parameters: Understanding these parameters is essential. They guide the selection of the correct valve type (standard, part-balanced, or fully balanced).

- Directional Valve Type: The type of directional valve used (closed-center or open-center) influences the balance valve selection.

- Counterbalance Valve Placement: This is critical, especially when using directional valves to the cylinder.

Placement and Configuration of Balance Valves in the Circuit

Proper placement of balance valves significantly impacts system stability and response time. The general rule is to place the valve where it best controls fluid distribution. This ensures effective operation.

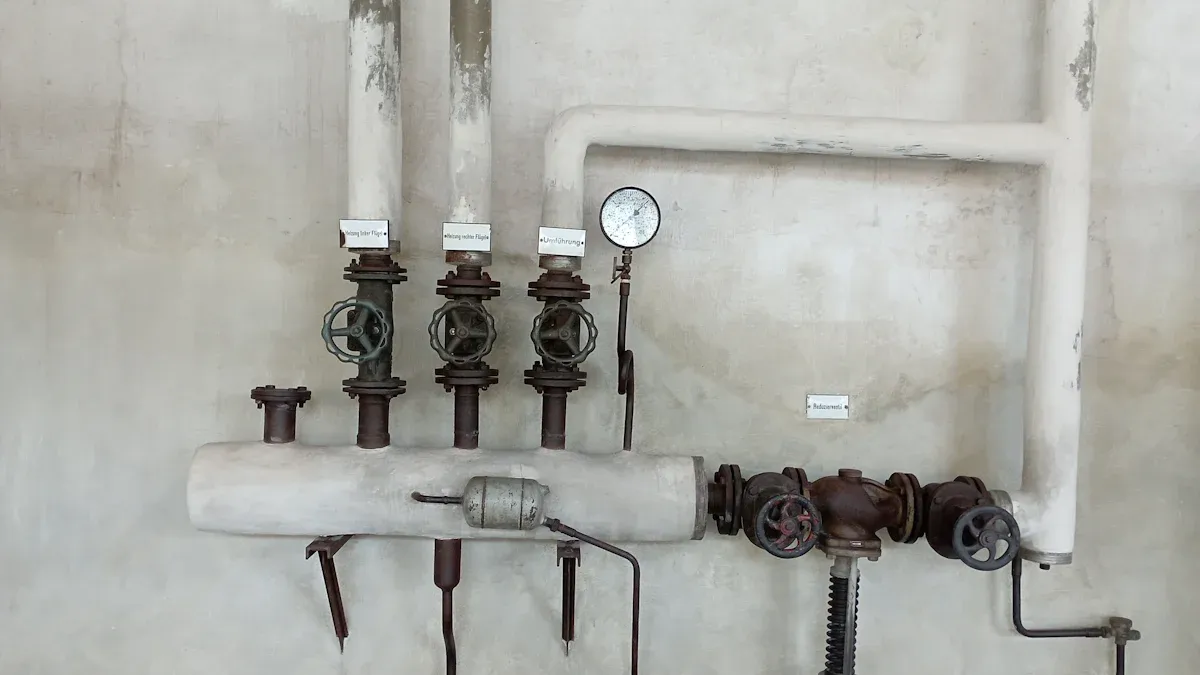

For HVAC systems, placing flow balancing valves on the return side of coils is often recommended. This placement helps reduce air and noise problems. It maintains higher water pressures within the coil. This keeps more air in solution and out of the coil. This approach does not compromise flow control.

Specific placement examples include:

- HVAC Systems:

- Chilled Water Systems: Valves typically install at the inlet or outlet of each cooling coil.

- Hot Water Systems: Valves install at the inlet or outlet of heating coils. In district heating, they are placed at building entrances.

- Plumbing Systems:

- Domestic Water Distribution Systems: Valves install at the main branches of the water supply pipes.

- Fire Sprinkler Systems: Valves install at the inlet of each sprinkler zone.

- Industrial Processes:

- Chemical Processing Plants: Valves install at the inlet and outlet of reactors, heat exchangers, and other process equipment.

- Oil and Gas Pipelines: Valves install at various points along the pipeline. These include junctions of different branches and entrances to storage tanks.

- Irrigation Systems:

- Agricultural Irrigation: Valves install at main water supply lines and at the inlets of individual irrigation zones.

- Landscape Irrigation: Valves control flow to different sprinkler heads and drip lines.

Balancing valve placement is crucial for its effectiveness. It typically goes on the flow or return side. This depends on the system and its function. In heating systems, valves are often on the return side. They regulate water flow back to the boiler. This ensures even distribution and consistent temperatures throughout the circuit. For cooling systems, such as chilled water, valves generally go on both supply and return sides. This ensures even chilled water flow and consistent temperatures. In plumbing systems, valves regulate flow in various branches. They distribute water evenly. This prevents issues like low or overpressure in different areas.

Reducing flow to eliminate instability is a common response for small downstream volumes. However, there is also a demand for faster response and more flow. The smallest restriction in a process dictates the maximum possible flow rate. This is true regardless of valve orifice size or differential pressure. For optimal stability and accuracy, the ideal solution involves valves within a proportional controller. These valves should be the smallest restriction in the process. This allows for aggressive PID tuning. Understanding process specifics, pressures, downstream volumes, and required flow rates is crucial for selecting a proportional controller. The dynamics of stability versus fill-time often require trade-offs.

Sizing and Pressure Setting Calculations for Balance Valves

Correctly sizing and setting the pressure of a balance valve is vital. This ensures safe and controlled operation. The cracking pressure is the pressure at which the relief valve starts to open. It is the pressure the gauge builds to when adjusting the valve.

Guidelines for setting the cracking pressure include:

- The counterbalance valve setting should be 30% higher than the load.

- The cracking pressure setting must be higher than the load pressure to hold the load.

- The typical counterbalance valve setting is roughly 30% above the load pressure. This ensures the reseat pressure is high enough to hold the load, accounting for hysteresis.

- The valve’s set pressure should be at least 1.3 times the maximum load pressure. This provides a safety margin.

Pressure at the exhaust of the valve directly adds to the spring setting of internally piloted valves. This increases their cracking pressure. For internally and externally piloted valves, exhaust pressure adds to the spring setting by a factor of four for a 3:1 pilot ratio valve. Designers must determine the counterbalance’s exhaust pressure. This helps them decide whether to use an external spring chamber drain. This drain lowers the release pressure.

Installation and Commissioning of Balance Valves

Proper installation and meticulous commissioning are crucial for balance valves. These steps ensure optimal hydraulic circuit performance. They also guarantee system safety and efficiency.

Best Practices for Balance Valve Installation

Correct installation of a balance valve prevents future operational issues. Engineers must first thoroughly review system layouts and flow requirements. They verify the valve’s size, type, and flow coefficient (Kv) match system specifications. This prevents inaccurate readings or unstable flow control.

Choosing the correct installation position is also vital. Installers select a location with stable flow conditions. They avoid turbulent areas immediately after pumps, elbows, or tees. Ideally, they ensure 10 pipe diameters of straight pipe upstream and 5 diameters downstream. This promotes laminar flow and accurate measurement. Installers always check the flow direction arrow on the valve body. Incorrect installation leads to inaccurate flow measurement, reduced performance, or valve damage.

Maintaining accessibility for the valve is another key practice. Installers place valves in easily accessible locations. They ensure sufficient clearance for technicians to connect measuring devices or adjust the handle. This facilitates periodic testing, adjustment, and maintenance. Proper connection and sealing are also essential. Technicians use compatible sealing materials, such as PTFE tape or thread sealant, for leak-free connections. For flanged or soldered joints, they ensure correct alignment and even tightening. This prevents mechanical stress and damage to the valve or measuring ports.

Finally, installers avoid air pockets. They install the valve in a horizontal pipe with test points facing upward. If installed vertically, they ensure proper air venting. This prevents trapped air from causing false readings and unstable flow rates. Bleeding air from the system during commissioning is also necessary.

The Commissioning Process: Step-by-Step Adjustment of Balance Valves

Commissioning a hydraulic system with balance valves involves a systematic approach. This process ensures the system operates as designed. It includes testing, adjusting, and balancing.

First, technicians perform comprehensive testing. They use specialized, calibrated instruments. These instruments quantitatively measure performance parameters. They check temperatures, pressures, rotational speeds, and flow rates. This evaluation occurs during equipment and system operation. ValveLink™ Software offers comprehensive diagnostics for control valve troubleshooting, tuning, and calibration. This software allows for root-cause analysis for individual valves without interrupting the process. Technicians also conduct pressure testing. This confirms sealing capability and structural integrity. It identifies leaks in seats, body joints, or packing. Performance signature testing records actuator movement. This helps detect mechanical issues like excessive friction or binding. Specialized valve test benches simulate operational conditions. They measure flow coefficients, pressure drops, and response characteristics. Ultrasonic testing is a non-disruptive method. It uses sound waves to detect internal flaws without disassembling the valve.

Next, the adjustment phase focuses on regulating fluid flow rates and air patterns at terminal equipment. This includes the final setting of balancing devices like dampers and valves. Technicians fine-tune fan speeds, pump impeller sizes, and control devices. This achieves specified system performance.

Finally, balancing involves the methodical regulation of system fluid flows. This occurs within the distribution system, including zones, branches, and terminals. Technicians use standardized procedures to match specified design quantities. Air balance testing is a comprehensive diagnostic method for HVAC systems, including valves. It surveys all system components to ensure peak performance. This process calibrates equipment, identifies necessary repairs, and aligns settings with desired performance.

Troubleshooting Common Balance Valve Commissioning Issues

During commissioning, several issues can arise with balance valves. Technicians must identify and resolve these problems quickly.

One common issue is valve chatter or instability. This often results from a pressure drop at the valve’s inlet. An improperly sized valve, especially one that is oversized for the application, also causes instability. Instability can occur at low flows when the valve opening is too small for effective modulation. Changing backpressure also contributes to instability. Trapped air and cylinder seal stick-slip are common alternative causes of instability. Other factors include excessive inlet pressure loss, often exceeding the 3% rule, or excessive back pressure, which can exceed the 10% rule. Incorrect flow rate due to improper initial setting, blockage within the balance valve from debris, or wear and tear over time also affect seals and internal components. Air entrainment in the system interferes with pressure readings and flow measurements. User error or lack of familiarity with proper valve adjustment, along with incorrect installation, such as wrong orientation or unsuitable location, also lead to problems.

Pressure spikes or surges are another concern. Pressure reducing regulators can mitigate these issues. They quickly adjust flow rates and reduce downstream pressure. This prevents overpressure conditions from sudden changes in supply pressure. Such changes occur during pump starts or valve closures. Counterbalance valves, also known as load-holding valves, also help. They act as adjustable pressure relief valves. They prevent oil from leaving the cylinder. This maintains load stability and reduces pressure pulsations. These valves prevent uncontrolled movements and pressure spikes in the line where they are installed. Adjustable springs in counterbalance valves should be set at least 30% above the maximum induced load pressure. This ensures proper reseating and prevents runaway loads. This indirectly helps mitigate pressure-related issues.

Long-Term Impact and Maintenance of Balance Valves

Maintaining optimal hydraulic performance requires ongoing attention to balance valves. Their long-term impact on system efficiency and safety is significant. Regular maintenance prevents costly downtime and extends equipment life.

Sustaining Performance: Monitoring and Adjustment of Balance Valves

Sustaining peak performance of hydraulic systems depends on consistent monitoring and timely adjustments of their components. Routine maintenance activities include valve inspection at predetermined intervals. Manufacturers often provide guidelines for these procedures. These guidelines are crucial for maintaining safe and reliable operation, especially in high-pressure environments. For internal valve components, an annual inspection is recommended. However, severe service valves and gas ball valves require shorter inspection intervals. Systems evolve over time. Valves drift, pumps age, and loads shift. What was optimally balanced at installation may not remain so years later. This necessitates scheduled re-checking and commissioning updates.

Preventing Wear and Failure in Balance Valves

Preventing wear and failure in a Balance Valve ensures continuous, reliable operation. Technicians perform periodic inspections of seals and gaskets. They check for wear, leaks, or deformities. Replacement occurs before full failure. Cleaning strainers and filters upstream prevents debris entry. Flushing lines removes sediment. Bleeding air from the system prevents flow disruption and inaccurate readings. Verifying valve settings and performance periodically is essential. This happens after commissioning, seasonal changes, or system modifications. Technicians revisit flow measurements and re-balance if needed. Lubrication of moving parts, if applicable, follows manufacturer specifications. This prevents sticking or excessive wear. Checking for corrosion or material degradation is also important, especially in aggressive environments. Replacement or refurbishment occurs as needed. Ensuring accessibility for valves and their test ports simplifies adjustment, measurement, or repairs.

Balance valves are more than mere components; they are foundational elements. They dictate the safety, efficiency, and longevity of hydraulic systems. These valves play a critical role from the initial design phase through continuous operation. Engineers must prioritize their proper integration for optimal system performance.

FAQ

What is the primary function of a balance valve?

A balance valve controls load movement in hydraulic circuits. It prevents uncontrolled acceleration. The valve ensures stable and precise operation.

How do balance valves prevent uncontrolled movement?

Balance valves act as load-holding brakes. They meter oil flow. This action prevents loads from “running away” due to gravity or external forces.

Do balance valves contribute to energy savings?

Yes, balance valves regulate fluid flow and pressure. This regulation optimizes system efficiency. It leads to reduced energy consumption. ⚡

Post time: Dec-24-2025