Predictive maintenance in pneumatic systems anticipates failures before they occur. This approach significantly reduces operational costs; organizations can see maintenance expenditures decrease by 20% to 30%. Industrial-grade sensors are pivotal for effective predictive maintenance in these systems. These advanced sensors provide the critical data necessary for anticipating potential issues.

Key Takeaways

- Industrial sensors help predict problems in pneumatic systems before they happen, saving money and preventing unexpected shutdowns.

- These sensors collect real-time data on pressure, flow, and temperature, allowing AI to find issues and suggest maintenance.

- Using these sensors makes equipment last longer, lowers repair costs, and makes workplaces safer.

Limitations of Traditional Maintenance and the Role of Sensors

Inefficiencies of Reactive Maintenance

Reactive maintenance involves repairing equipment only after it fails. This approach causes significant operational disruptions. Unplanned downtime becomes a major consequence. Organizations face substantial financial losses. The United States Department of Energy estimates that implementing predictive maintenance can reduce downtime by 35% to 45%. Facilities utilizing predictive or preventive maintenance experienced 52.7% less downtime compared to those relying on reactive maintenance. This highlights the severe inefficiencies of a reactive strategy.

Shortcomings of Time-Based Preventive Maintenance

Time-based preventive maintenance schedules equipment servicing at fixed intervals. This method often leads to unnecessary work. Most equipment failures do not relate to age. This approach creates a false sense of security. It results in wasted resources. For example, ignoring preventive maintenance in pneumatic systems can lead to leaks and component wear. These issues cause efficiency losses and increased operating costs. A significant percentage of failures follow unpredictable trends, making fixed schedules inefficient.

Bridging Gaps with Advanced Sensors

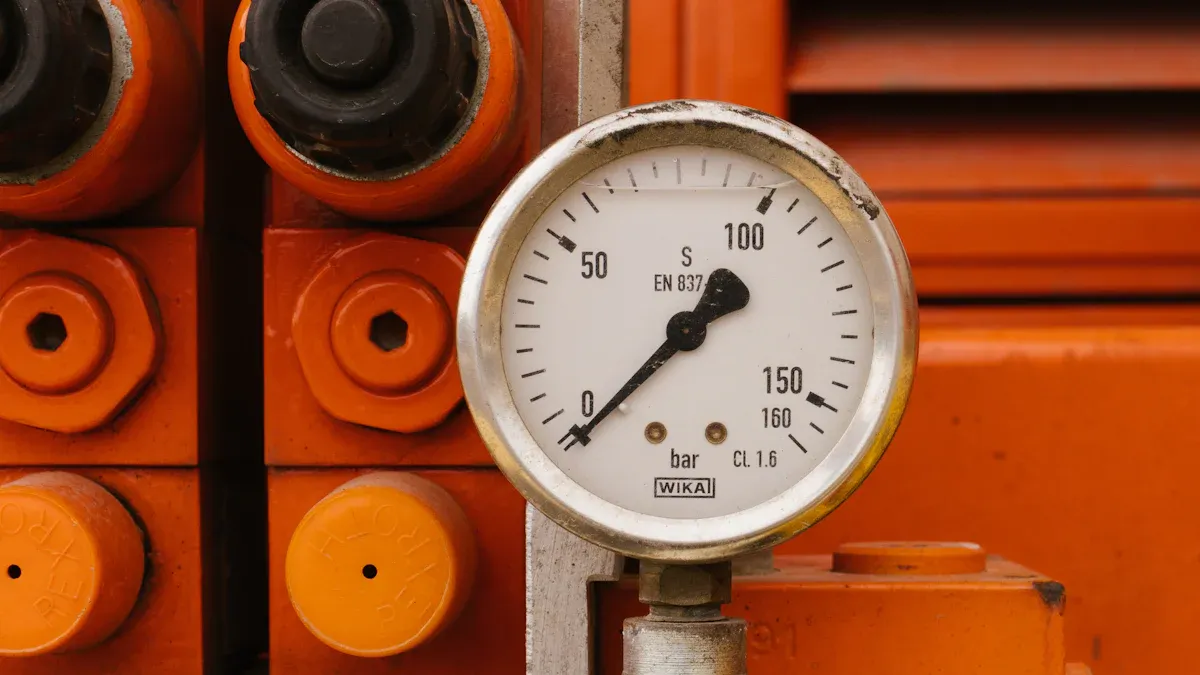

Advanced industrial-grade sensors address the limitations of traditional maintenance. They provide continuous, real-time data about system health. Pressure transducers detect variations indicating leaks or other issues. Vibration monitoring and temperature measurement offer comprehensive insights. Differential pressure devices identify airflow drops, signaling clogs or inefficiencies. These specialized components enable proactive identification of potential problems. They transform maintenance from reactive or time-based to condition-based.

How Industrial-Grade Sensors Power Predictive Maintenance in Pneumatic Systems

Real-Time Data Collection with Integrated Sensors

Industrial-grade sensors continuously monitor pneumatic systems. They collect vital data in real-time. This constant stream of information forms the foundation of predictive maintenance. The update frequency for these sensors is critical. It determines how often new data points become available. For example, a system with 50 monitoring points sampling at one-second intervals achieves a 1 Hz sampling rate for those specific points.

Communication protocols facilitate this data transfer. Selecting the right protocol depends on several factors. These include the volume of data each component generates, the required update frequency, control requirements, and existing infrastructure.

| Protocol | Data Rate |

|---|---|

| IO-Link | 230 kbps |

| MQTT | Variable |

| OPC UA | Variable |

| EtherNet/IP | 10/100 Mbps |

| PROFINET | 100 Mbps |

Integrating diverse sensor data streams for real-time monitoring presents challenges. Organizations manage vast amounts of dynamic data from billions of connected devices. This data comes in various formats, including numerical, audio, and video. Handling this data across distributed systems requires sophisticated strategies for storage, processing, and integration. Edge devices often operate under strict limitations in computational power, memory, and energy. This necessitates innovative approaches like lightweight AI models. Ensuring seamless connectivity and interoperability between diverse devices and platforms also poses a significant hurdle. Maintaining data accuracy, reliability, and consistency becomes more difficult as the number of devices grows. Issues like data duplication or loss can undermine application effectiveness. Robust security mechanisms are also essential. Data flowing across IoT devices, cloud infrastructures, and edge nodes faces risks of breaches and unauthorized access.

Key Sensor Types and Their Applications

Various industrial-grade sensors play crucial roles in monitoring pneumatic system health. Each type targets specific parameters, providing comprehensive insights.

- Pressure Sensors: These devices detect anomalies like leaks and blockages. They identify unusual increases or decreases in air transmission. Such variations indicate inefficient operation, potential equipment damage, or impending unplanned shutdowns.

- Flow Sensors: Flow measurement devices identify leaks by detecting flow when a specific system part is shut down. Any observed flow under these conditions directly indicates a leak. Mass flow leak testing offers a direct measurement of leak rates. This method often proves superior to pressure decay methods. It is less susceptible to adiabatic effects. Specialized flow meters can measure extremely low flow rates, down to 0.0025 ml/min, crucial for detecting very fine leaks.

- Temperature Sensors: Temperature sensors monitor the health of pneumatic actuators and valves. They detect overheating. An overheated actuator can signal motor wear or a restricted component within the valve. This detection necessitates immediate investigation to prevent severe damage. These sensors also improve energy efficiency. They provide real-time data to control systems, optimizing heating and cooling cycles. This reduces standby losses and prevents overheating.

- Acoustic and Vibration Sensors: These sensors are vital for early detection of mechanical wear. Acoustic monitoring, specifically ultrasonic sensors, detects early bearing wear. Vibration analysis identifies issues like bearing wear and misalignment. Vibration sensors convert changes in vibration into electrical signals. They provide data on displacement, velocity, and acceleration. Abnormal measurements indicate hidden problems or machinery failures. Both methods contribute to detecting early warning signs of problems. They provide real-time insights and enable predictive maintenance.

Data Analysis and Failure Prediction with AI/ML from Sensor Data

AI and machine learning algorithms analyze the vast amount of sensor data. They identify patterns and predict potential failures. These advanced analytical tools transform raw data into actionable insights.

Several machine learning algorithms prove effective for anomaly detection in pneumatic system sensor data:

- Cluster-based methods (e.g., KMeans): These methods group sensor data based on similarities. Anomalies are identified when new measurements fall into small or distant clusters.

- One-Class SVM: This algorithm learns the normal behavior of data by establishing a boundary. Data points outside this boundary are flagged as potential anomalies.

- Isolation Forest: This unsupervised learning method isolates outliers. It recursively splits data based on random features and values.

Other effective methods include statistical profiling, Bayesian networks, and local outlier factor analysis. These algorithms process complex datasets. They detect subtle deviations from normal operating conditions.

Modern predictive maintenance software utilizes machine learning to analyze historical sensor data. This includes pressure changes. The software identifies patterns and predicts failures. Dashboards are commonly used to display equipment health scores, trending data, and maintenance recommendations. These dashboards present insights in an easy-to-understand format. Data visualization translates complex maintenance data, including sensor readings, into clear, comprehensible visuals. Charts, graphs, and dashboards provide clarity and context. They offer real-time insights, improve operational efficiency, and enable trend analysis. Dashboards aggregate essential data into a single interface. This provides an overview of asset health and performance.

Tangible Benefits of Sensor-Driven Predictive Maintenance

Minimizing Unplanned Downtime

Sensor-driven predictive maintenance significantly reduces unplanned downtime. This approach allows organizations to address potential issues before they escalate into critical failures. Unplanned downtime costs industries an estimated $50 billion annually. Furthermore, it accounts for approximately 11% of turnover in Fortune Global 500 companies. By predicting equipment failures, companies avoid these costly interruptions. This proactive strategy ensures continuous operation and maintains production schedules.

Optimizing Energy Consumption and Operational Efficiency

Predictive maintenance, powered by advanced sensors, greatly optimizes energy consumption and overall operational efficiency. User data from pneumatic devices, combined with edge gateways, provides insights that inform maintenance decisions. This directly improves system availability. Device-level data measures and monitors speed and device cycle time, directly impacting system performance and throughput. Data provided through edge gateways and visualization software can be quickly analyzed and interpreted. This pinpoints the root causes of quality issues, leading to improved product quality.

Intelligent pneumatics enable real-time inspection and adjustment during manufacturing processes. Sensors detect defects or deviations, triggering immediate corrective actions. This reduces scrap rates and rework costs. For example, automotive assembly lines use smart pneumatics for precise component placement. This leads to fewer errors and higher throughput. Outcome metrics include a 20-30% reduction in defect rates and a 15% increase in throughput. Pneumatics directly impact the Overall Equipment Effectiveness (OEE) of a machine or production line when properly sized and designed. Today’s pneumatics provide valuable insights and monitoring capabilities to address industry concerns. Pneumatic controls offer OEE improvement and predictive maintenance, leading to cost savings in the field and during the design phase of machines.

Extending Equipment Lifespan and Reducing Costs

Sensor-driven predictive maintenance extends equipment lifespan and substantially reduces costs. Overall maintenance costs decrease by 18-25% compared to traditional methods. This approach achieves savings of 8-12% over preventive maintenance strategies. Companies can realize up to 40% savings compared to reactive maintenance strategies. Emergency repairs, which predictive maintenance helps avoid, typically cost 3-5 times more. Intelligent pneumatics continuously monitor equipment health by tracking parameters like pressure, flow, and vibration. This allows for the prediction of failures before they occur, minimizing downtime and extending equipment lifespan. Automated conveyor systems with smart pneumatics can alert operators to potential issues, preventing costly breakdowns. Logistics firms report up to a 25% reduction in maintenance costs due to the ability to preempt failures.

Enhancing Safety and Reliability

Predictive maintenance significantly enhances safety and reliability in pneumatic systems. Monitoring key performance indicators like pressure and flow allows for the prediction of most pneumatic component failures, particularly leaks, which often precede larger issues. Condition-Based Maintenance (CBM) programs, enabled by continuous monitoring of operational conditions, minimize inspection, repair, and replacement costs by addressing issues proactively. An Automated Monitoring System (AMS) provides real-time pressure and flow data, identifying future maintenance needs before machine or line stoppage occurs. Alarms can be set for deviations from baseline levels, signaling the need for inspection.

Integrating Supervisory Control and Data Acquisition (SCADA) systems watches for outliers and compares them to baseline data. Artificial Intelligence (AI) can map pressure and flow data against a machine’s motion profile. This identifies specific failing circuit portions, allowing for pre-ordering of repair parts and scheduled maintenance. Monitoring pressure, flow, and temperature establishes baseline conditions. Deviations trigger preventative actions, leading to optimized air consumption, increased life of pneumatic components, and improved production process decision-making.

Intelligent pneumatic systems incorporate sensors to monitor safety parameters, ensuring compliance with industry standards. They can trigger alarms or shut down processes if unsafe conditions are detected. For example, a pharmaceutical plant uses smart pneumatics to monitor air quality and pressure, ensuring sterile conditions and preventing contamination risks. Robots powered by intelligent pneumatics adapt their movements based on sensor feedback, improving handling precision and reducing errors. In electronics assembly, such robots dynamically adjust grip strength to prevent damage to delicate components. These systems support more complex, adaptive tasks, boosting productivity and quality as robotics integrate with AI.

IIoT sensors in pneumatic devices measure key operating parameters such as temperature, pressure, flow rates, and cycle times. This data allows for closer monitoring of machine performance. Edge devices, like the AVENTICS smart pneumatics monitor, capture and analyze this data locally, comparing performance to design parameters. This local processing enables the system to send alerts for outlier data, ensuring timely intervention. An increase in cycle speed, even by milliseconds, can indicate a deteriorating shock absorber, allowing for predictive maintenance and improved reliability.

Industrial-grade sensors are indispensable for modern pneumatic system maintenance. They provide critical data. Embracing sensor-driven predictive maintenance leads to significant operational advantages. This approach ensures greater efficiency and cost savings. The future of pneumatic system reliability is intrinsically linked to advanced sensing technologies.

FAQ

What defines an “industrial-grade” sensor?

Industrial-grade sensors offer robust construction, high accuracy, and reliability. They withstand harsh industrial environments. They ensure consistent performance in demanding applications.

How do sensors connect to the predictive maintenance system?

Sensors transmit data using various communication protocols. These include IO-Link, MQTT, and EtherNet/IP. Edge devices often process data locally before sending it to a central system.

Is predictive maintenance expensive to implement?

Initial investment in sensors and software is necessary. However, predictive maintenance significantly reduces long-term operational costs. It prevents costly downtime and extends equipment life.

Post time: Dec-31-2025