Material choices for wire, insulation, and encapsulation directly influence Solenoid Coils performance and durability. The specific properties of these materials establish a direct link to the operational lifespan under diverse conditions. Understanding each component’s material science is crucial for achieving overall solenoid reliability.

Key Takeaways

- Choosing the right wire material, like copper, helps solenoid coils work well. Copper lets electricity flow easily and helps cool the coil.

- Good insulation protects the coil from electrical problems and damage. It keeps the coil safe from heat and moisture.

- Encapsulation acts as a strong outer shield for the coil. It protects the coil from dirt, water, and bumps, making it last longer.

Wire Materials: The Foundation for Reliable Solenoid Coils

Copper’s Role in Solenoid Coils: Conductivity and Heat

Copper is a primary choice for wire in many applications. It offers excellent electrical conductivity. This property allows current to flow efficiently with minimal energy loss. Copper also possesses high thermal conductivity. This helps dissipate heat generated during operation, preventing overheating and extending the lifespan of the component.

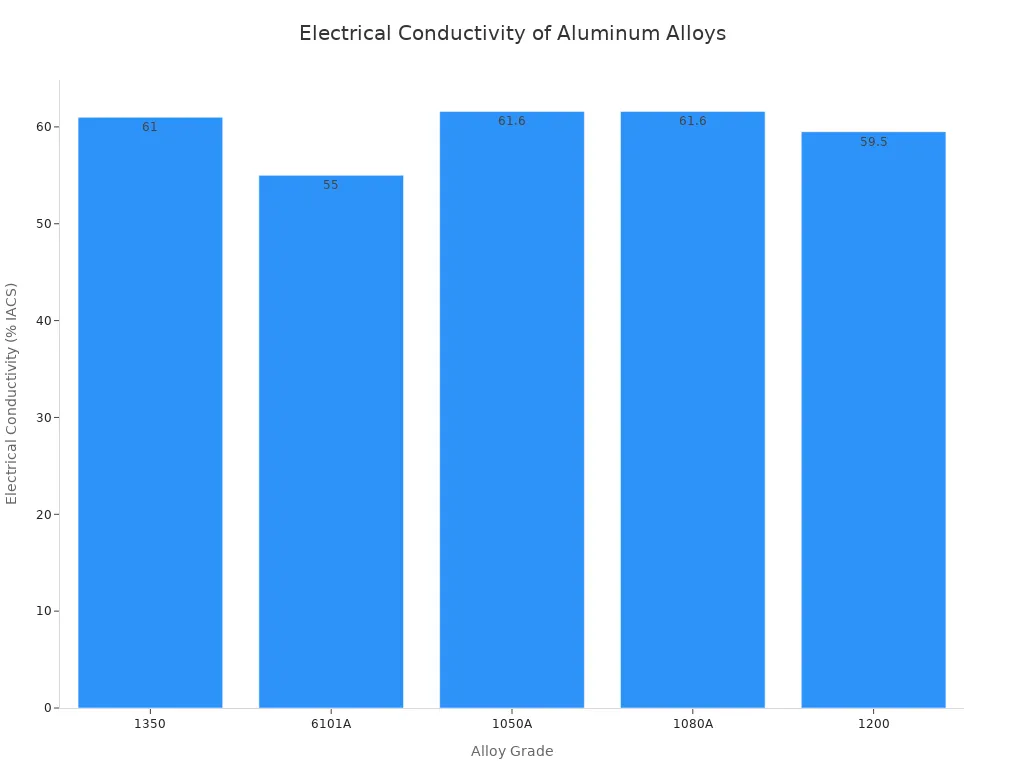

Aluminum in Solenoid Coils: Weight, Cost, and Conductivity Trade-offs

Aluminum presents an alternative to copper. It offers advantages in weight and cost. Aluminum wire is lighter and generally less expensive than copper. However, aluminum has lower electrical conductivity. This means a larger cross-section of aluminum wire is often needed to achieve similar electrical performance as copper. Different aluminum alloys offer varying conductivity levels.

Specialty Alloys for Demanding Solenoid Coil Performance

Some applications require materials beyond standard copper or aluminum. Specialty alloys address specific performance needs. These alloys can offer enhanced properties. Examples include improved high-temperature resistance, superior mechanical strength, or better corrosion resistance. Engineers select these alloys for extreme operating conditions.

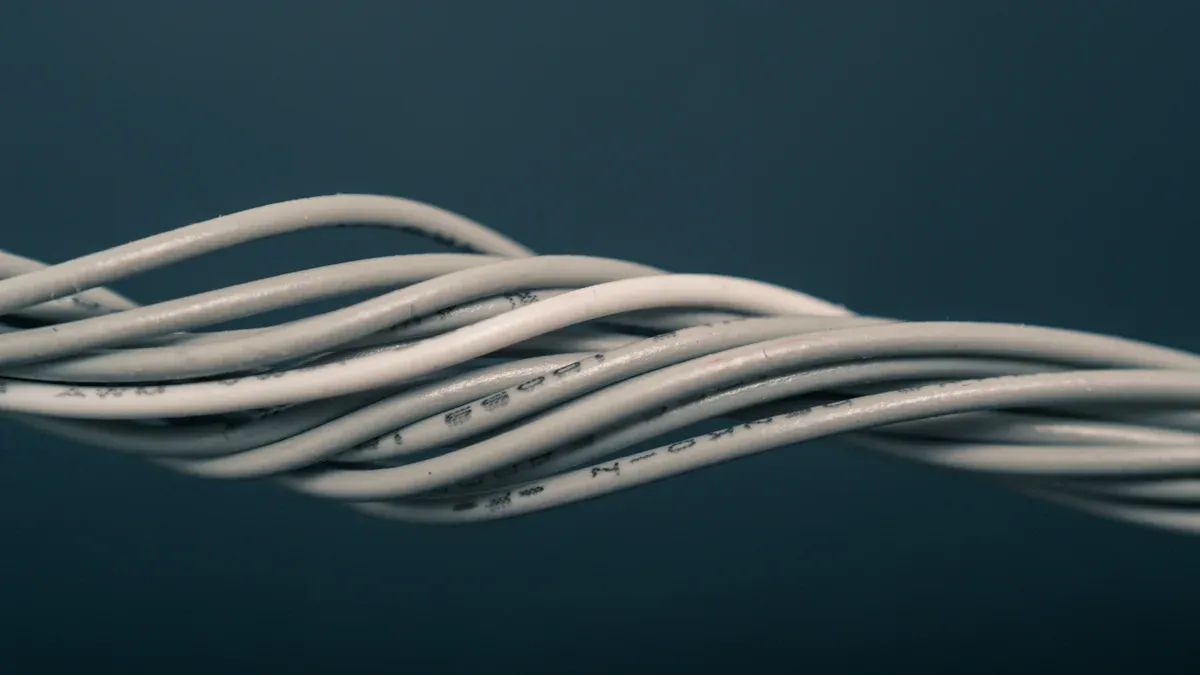

Wire Gauge and Strand Count: Impact on Solenoid Coil Current and Flexibility

Wire gauge significantly impacts a coil’s performance. A thicker wire has lower electrical resistance. This allows it to carry more current without excessive heat buildup. However, thicker wire also requires more space within the coil. The wire gauge and insulation type directly affect the coil’s resistance and current-carrying capacity. Strand count also matters. Wires with more strands are more flexible. This makes them suitable for applications requiring repeated bending or vibration.

Insulation Materials: Protecting Solenoid Coils from Electrical Breakdown

Enamel Coatings: Dielectric Strength and Thermal Class for Solenoid Coils

Enamel coatings provide the primary electrical insulation for wire in Solenoid Coils. These thin layers possess high dielectric strength, preventing electrical current from escaping the wire. Manufacturers classify enamels by their thermal class, indicating the maximum continuous operating temperature they can withstand without degradation. For instance, polyester enameled wire often finds use in solenoid valves, typically rated for 130℃ or 155℃. Polyurethane enameled wire, also rated for 130℃, serves in relays, micromotors, and ignition coils.

| Thermal Class | Uses or Applications (for Solenoid Coils) |

|---|---|

| 130℃, 155℃ | Solenoid valves (Polyester enameled wire) |

| 130℃ | Relays, micromotors, small transformers, degaussing coils, ignition coils, water stop valves, magnetic heads, wires for communication equipment (Polyurethane enameled wire) |

Tapes and Sleeving: Enhancing Solenoid Coil Protection

Beyond enamel, tapes and sleeving offer additional layers of protection. These materials provide mechanical reinforcement, abrasion resistance, and further electrical insulation. Tapes can secure windings, while sleeving protects lead wires from environmental damage or short circuits. They enhance the overall robustness of the coil assembly.

Dielectric Strength and Thermal Class: Key Reliability Metrics for Solenoid Coils

Dielectric strength measures an insulating material’s ability to resist electrical breakdown under voltage stress. Thermal class defines the maximum temperature an insulation system can endure over its expected lifespan. Both metrics are crucial for predicting a coil’s reliability and longevity. Industry standards like ASTM D149 measure breakdown voltage in solid materials. IEC 60243 defines testing for electrical insulating materials. IEEE 4 provides guidelines for high-voltage testing. For AC dielectric constant and dissipation factor, ASTM D150 and IEC 60250 offer standardized testing methods.

Environmental Resistance of Solenoid Coil Insulation: Moisture and Chemical Protection

Insulation materials must also protect against environmental factors like moisture and chemicals. Moisture ingress can significantly reduce dielectric strength, leading to premature failure. Chemical exposure, common in automotive or industrial settings, can degrade insulation properties. Fluoropolymer coatings, such as PTFE, enhance chemical resistance, offering protection against corrosive substances. Specialized polymers like PET (Polyethylene Terephthalate) offer exceptional thermal and chemical resistance, making them suitable for harsh environments like automotive transmissions. Polyester-Polyimide (PEI) provides excellent thermal stability and moisture resistance, ideal for aerospace actuators.

Encapsulation Materials: The Outer Shield for Solenoid Coils

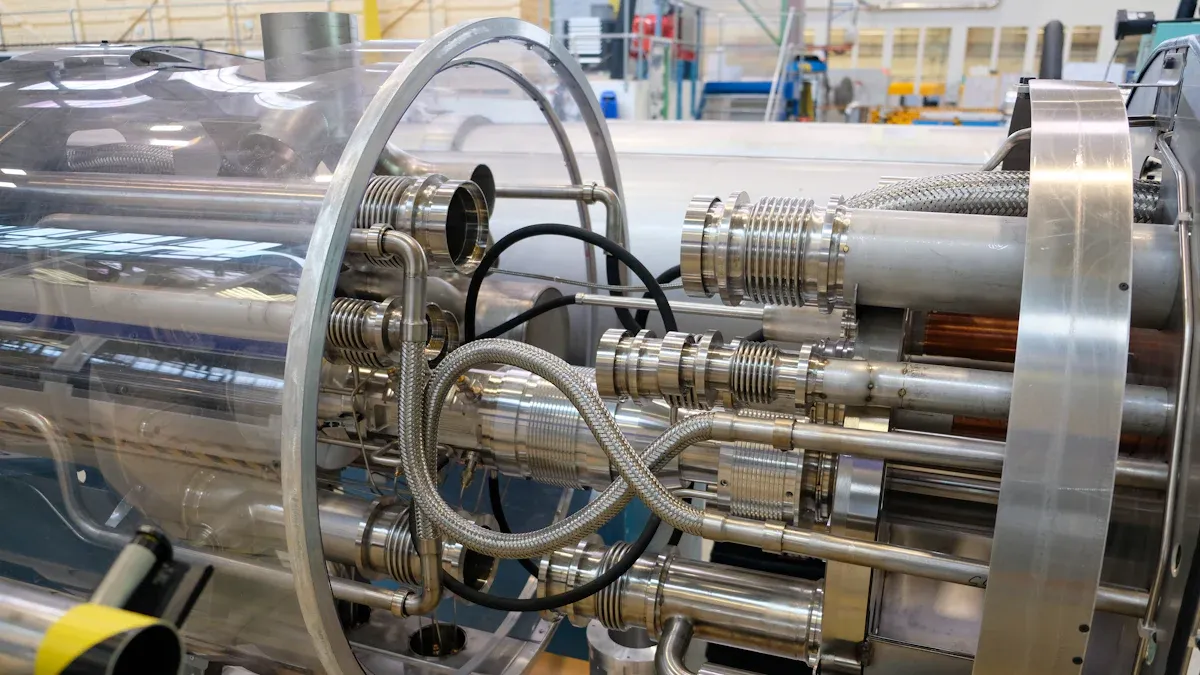

Potting Compounds for Solenoid Coils: Mechanical Strength and Environmental Sealing

Potting compounds form a robust outer layer for Solenoid Coils. They provide crucial mechanical strength and environmental sealing. Common potting materials include epoxy, polyurethane, and silicone. Epoxy compounds offer excellent adhesion and chemical resistance. Silicone compounds provide greater flexibility and improved resistance to vibration and thermal cycling. These materials protect the internal components from physical damage and external elements.

| Potting Compound Type | Mechanical Strength Properties |

|---|---|

| Urethane (Epic S7318) | Low hardness |

| Epoxy (Epic S7230) | Vibration and shock resistance, improved resistance to thermal shock |

| Polyurethane (Epic S7214) | Rapid hardness development, advanced protection against vibration |

| Epoxy (Epic 0229) | Exceptional toughness |

Effective potting compounds achieve high ingress protection (IP) ratings. Encapsulated or "potted" solenoids often receive ratings such as IP65, IP67, or IP69K.

Thermoplastics and Thermosets in Solenoid Coils: Molding and Overmolding Benefits

Thermoplastics and thermosets offer significant benefits through molding and overmolding processes. These materials allow for complex shapes and integrated features. Molding provides a consistent, protective housing. Overmolding creates a seamless bond between the coil and its outer shell. This enhances durability and simplifies assembly.

Thermal Management in Solenoid Coils: Dissipating Heat Effectively

Effective thermal management is vital for coil longevity. Encapsulation materials play a role in heat dissipation. Engineers use several methods to manage heat:

- Proper Installation: Install the coil in a well-ventilated area. Avoid enclosed spaces where heat can build up. Improve air circulation with fans or ventilation ducts.

- Cooling Solutions: Utilize heat sinks made of aluminum or copper. These absorb and transfer heat to the surrounding air. Liquid cooling systems can provide more efficient heat removal for high-power applications.

- Thermal Management Design: Incorporate design features like heat-dissipating fins and ventilation channels. Arrange coils to maximize air circulation. Use materials with good thermal properties for enclosures.

Environmental Protection for Solenoid Coils: Sealing Against the Elements

Encapsulation materials provide the ultimate shield against harsh environments. They seal the coil against moisture, dust, and chemicals. This protection prevents corrosion and electrical shorts. The robust seal ensures reliable operation in demanding conditions. This directly contributes to the long-term performance of Solenoid Coils.

Synergistic Effects: How Materials Interact for Solenoid Coil Reliability

Thermal Expansion Mismatch in Solenoid Coils: Preventing Premature Failure

Materials within a coil assembly expand and contract at different rates when temperatures change. This phenomenon is thermal expansion mismatch. It creates internal stresses. These stresses can lead to premature failure. For example, delamination of the superconducting layer can occur. This happens around the conductor’s edge. The mismatch of thermal contraction coefficients among the former, epoxy, and HTS conductors causes this. Impregnation materials like epoxy can worsen delamination issues. This is especially true when a soft metallic layer is absent to accommodate the thermal mismatch. Degradation of RE123 CCs also happens. The brittle adhesive buffer/RE123 assembly layer detaches or breaks. Various stresses, including tensile, shear, compressive, cleavage, and peel, inherent in adhesive joints, cause this. Initial cracks in the RE123 layer can form during tape slitting. These cracks easily propagate under small applied transverse tension. This is particularly true when epoxy resin with unmatched thermal contractions fills the winding. Engineers must carefully select materials with similar thermal expansion coefficients. This prevents these damaging internal stresses.

Chemical Compatibility in Solenoid Coils: Avoiding Material Degradation

Materials must coexist without adverse chemical reactions. This is chemical compatibility. Incompatible materials can degrade over time. This degradation compromises performance and lifespan. UL Solutions evaluates electrical insulation systems (EIS). They determine if components interact unsafely. They also check for chemical reactions at certain maximum temperatures. This assessment is crucial. Such interactions can cause product failure or other hazards. UL Solutions verifies the chemical compatibility of unique material combinations within an EIS. This includes materials in motors, transformers, and solenoids. They test these combinations at specific maximum temperatures. Sealed tube chemical compatibility testing is part of this process. This test occurs when adding new minor components, like fastening tapes or tie cords, to an existing EIS. This rigorous testing ensures long-term reliability.

Manufacturing Processes: Impact on Solenoid Coil Material Integrity

Manufacturing processes directly impact material integrity. Winding tension and coil forming are critical steps. These processes can introduce defects or stress materials. Winding design significantly influences wire insulation integrity. This happens primarily through thermal management and precision. Inadequate thermal design creates hotspots within the winding. Copper losses, eddy-current losses, and hysteresis cause these hotspots. These hotspots directly degrade insulation. They shorten its lifespan. This can cause premature failure. Precision in winding is also crucial. Inconsistent winding geometry results in uneven current distribution. This creates localized hotspots. These hotspots compromise insulation integrity. The insulation system itself is fundamental. It comprises materials like enamel coatings, Nomex, and Kapton. Material selection depends on voltage and temperature ratings. A poorly chosen or implemented insulation system can lead to dielectric failure or corona. This is especially true in high-voltage applications.

- Thermal Management: Winding design must account for heat generation and dissipation. Hotspots from copper, eddy-current, and hysteresis losses degrade insulation. They reduce lifespan and cause premature failure.

- Precision Winding: Inconsistent winding geometry leads to uneven current distribution. This creates hotspots. It can also cause poor coupling or increased electromagnetic interference (EMI). All these factors indirectly stress insulation.

- Insulation Systems: The choice and quality of insulation materials are fundamental. These include enamel, Nomex, and Kapton. They are used between turns, layers, and the core. A deficient insulation system can result in dielectric failure or corona in high-voltage windings.

Selecting Materials for Optimal Solenoid Coil Performance and Lifespan

Key Factors for Wire Material Selection in Solenoid Coils

Selecting the correct wire material is fundamental for solenoid coil performance. Engineers must consider several critical electrical and mechanical properties. High electrical conductivity is crucial for minimizing power losses and enhancing electrical efficiency. Copper is the primary conductor material. It offers excellent electrical efficiency. Solenoid Coils generate heat. Therefore, materials with high heat resistance are essential. This prevents thermal damage and ensures long-term reliability. The coil must also withstand mechanical stresses like vibration and shock. Materials with good mechanical strength and flexibility provide necessary protection. In corrosive environments, materials with good chemical resistance prevent corrosion and ensure longevity. The choice of core material and insulation type also significantly impacts performance.

Critical Considerations for Solenoid Coil Insulation Material Selection

Insulation material selection depends heavily on the operating environment. Environmental factors like temperature, humidity, and exposure to chemicals directly influence material choice. In high-temperature environments, seals may soften or deform. Coils may overheat. Freezing conditions can cause residual moisture in the valve body to expand. This expansion may lead to cracking or blockage. Manufacturers provide temperature ratings for solenoid valves. These ratings guide material selection.

| Class | Maximum Temperature (Degrees C) |

|---|---|

| A | 105 |

| B | 130 |

| F | 155 |

| H | 180 |

For demanding environments, engineers consider models with thermoplastic encapsulated coils or PTFE seals. IP-rated enclosures resist moisture and dust ingress. To manage heat, engineers can mount the solenoid on a metal surface. This surface acts as a heat sink. Using forced air cooling or a larger size solenoid also helps. Intermittent operation (ON-OFF intervals) or using a solenoid with multiple windings can reduce heat buildup.

Choosing Encapsulation Materials for Specific Solenoid Coil Applications

Encapsulation materials provide the outer shield for solenoid coils. They offer crucial protection against environmental and mechanical stresses. In high-vibration applications, encapsulated coils enhance resistance to both vibration and moisture. Potting compounds like epoxy, polyurethane, or silicone are common choices. These materials shield the wound coil from moisture, heat, and vibration. Metal housings provide superior mechanical protection in areas prone to high impact. Engineers select encapsulated coils with high IP ratings for robust environmental sealing. Corrosion-resistant valve bodies and sealed or explosion-proof designs are also important considerations for specific applications.

Meticulous material selection profoundly influences solenoid coil longevity. Understanding specific properties and synergistic effects is crucial for designing reliable coils. Advancements in material science will continue to enhance future solenoid coil capabilities. Engineers prioritize these factors for optimal performance and extended operational life.

FAQ

What makes copper a preferred material for solenoid coils?

Copper offers excellent electrical conductivity. It minimizes power loss. Copper also efficiently dissipates heat. This ensures reliable, long-lasting solenoid operation.

Why is insulation crucial for solenoid coil reliability?

Insulation prevents electrical current from escaping the wire. It protects against short circuits. Insulation also guards against environmental damage. This ensures the coil’s electrical integrity and safety.

How does encapsulation protect solenoid coils from environmental factors?

Encapsulation provides mechanical strength. It offers environmental sealing. Encapsulation shields the coil from moisture, dust, chemicals, and physical impact. This extends the coil’s lifespan.

Post time: Dec-03-2025