Selecting the right pressure sensor plays a crucial role in hydraulic systems. Accurate measurements ensure optimal system performance, while durable sensors withstand harsh conditions. Key considerations include measurement range, environmental factors, and maintenance requirements. These elements significantly influence the efficiency and reliability of hydraulic operations.

Key Takeaways

- Choose the right pressure sensor type based on your application. Strain gauge sensors offer high accuracy, while piezoelectric sensors excel in dynamic situations.

- Consider environmental factors when selecting a sensor. Ensure it can withstand temperature, humidity, and exposure to corrosive substances for long-lasting performance.

- Regular calibration and maintenance are essential. Follow manufacturer guidelines to keep sensors accurate and reliable, reducing the risk of system failures.

Types of Pressure Sensors

Strain Gauge Sensor

Strain gauge sensors measure pressure by detecting changes in electrical resistance caused by deformation. These sensors offer high accuracy and reliability, making them a popular choice in hydraulic systems. Their ability to provide precise measurements ensures optimal performance in various applications.

Piezoelectric Sensor

Piezoelectric sensors generate an electrical charge when pressure is applied to piezoelectric materials. This characteristic makes them highly sensitive and suitable for dynamic applications, such as monitoring rapid pressure changes in hydraulic systems. Their quick response time enhances system efficiency.

Capacitive Sensor

Capacitive sensors operate by detecting changes in electrical capacitance resulting from diaphragm deflection. They excel in static pressure measurements, providing stable readings over time. These sensors are particularly useful in environments where consistent pressure monitoring is essential.

Optical Sensor

Optical sensors utilize light to measure pressure changes. They offer advantages such as immunity to electromagnetic interference and high sensitivity. These sensors are ideal for specialized applications where traditional sensors may struggle, such as in extreme environments.

| Sensor Type | Working Principle | Advantages |

|---|---|---|

| Strain Gauge Sensor | Measures pressure by detecting changes in electrical resistance due to deformation | High accuracy and reliability |

| Capacitive Sensor | Measures pressure by detecting changes in electrical capacitance from diaphragm deflection | Good for static pressure measurements |

| Piezoelectric Sensor | Generates an electrical charge when pressure is applied to piezoelectric material | Highly sensitive, suitable for dynamic applications |

Applications of Pressure Sensors in Hydraulic Systems

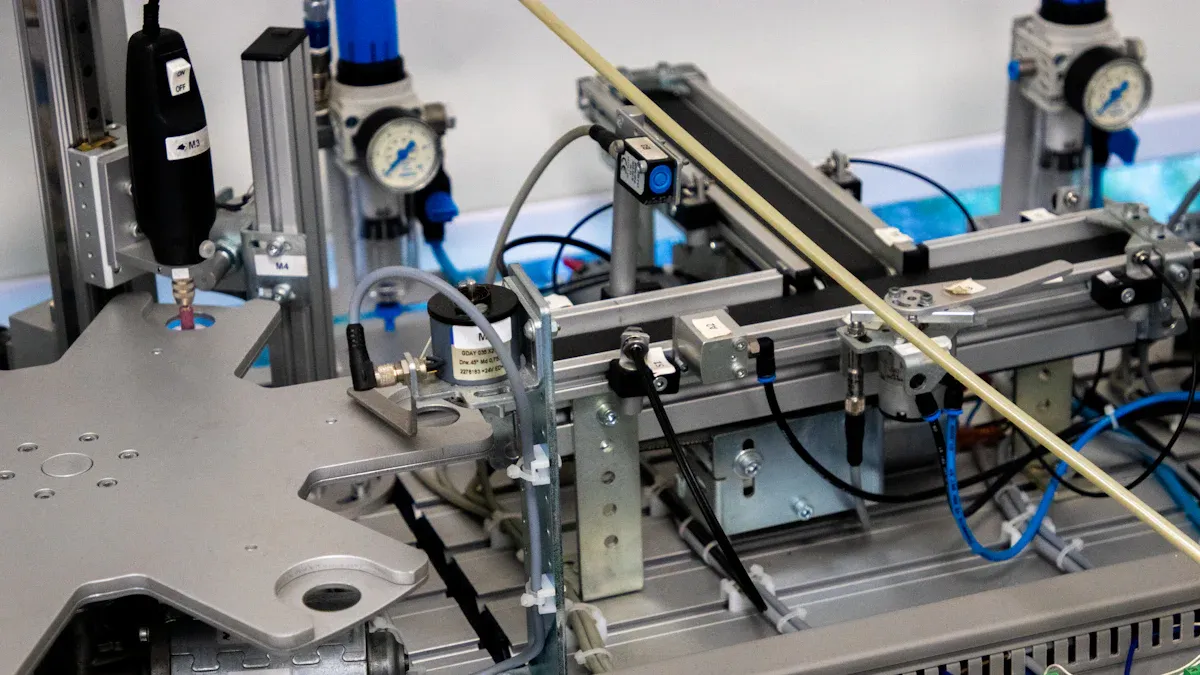

Industrial Machinery

Pressure sensors play a vital role in industrial machinery. They ensure efficient operation by monitoring and controlling hydraulic pressure. These sensors help maintain optimal performance in various manufacturing processes. Key functions of pressure sensors in this sector include:

| Function | Description |

|---|---|

| Process Control | Monitors and controls pressure in manufacturing processes. |

| Hydraulic Systems | Measures pressure in hydraulic machinery and equipment. |

| Leak Detection | Identifies leaks in pipelines and storage tanks. |

By providing real-time data, pressure sensors enhance productivity and safety in industrial environments.

Automotive Systems

In automotive systems, pressure sensors contribute significantly to vehicle performance and safety. They monitor hydraulic pressure in braking systems, power steering, and suspension systems. Accurate pressure readings ensure that these systems function correctly, preventing failures that could lead to accidents.

Moreover, modern vehicles often integrate pressure sensors with onboard diagnostics. This integration allows for early detection of potential issues, enabling timely maintenance and reducing repair costs.

Aerospace Applications

Aerospace applications demand the highest standards of accuracy and reliability. Pressure sensors in this field monitor hydraulic systems that control flight surfaces, landing gear, and other critical components. The sensors must withstand extreme conditions, including high altitudes and varying temperatures.

Engineers often select specialized sensors designed for aerospace use. These sensors provide precise measurements, ensuring safe and efficient aircraft operation. Their durability and performance are crucial for maintaining safety standards in aviation.

Marine Equipment

Marine equipment relies heavily on pressure sensors for performance monitoring. These sensors help manage hydraulic systems in vessels, ensuring smooth operation in challenging environments. They monitor pressure levels in steering systems, stabilizers, and other hydraulic components.

The following table outlines various pressure sensor models used in marine applications:

| Sensor Model | Pressure Range | Thread Type | Max Pressure | Operating Temperature | Voltage Range | Warning Contact |

|---|---|---|---|---|---|---|

| VDO 360-081-029-001C | 0-5 Bar (0-72.5 PSI) | M10 x 1 | 30 Bar (short duration) | -25°C to +100°C | 6 – 24 V DC | Optional |

| VDO 360-081-029-004C | 0-5 Bar (0-72.5 PSI) | 1/8 – 27 NPTF | 30 Bar (short duration) | -25°C to +100°C | 6 – 24 V DC | Optional |

| VDO 360-081-030-009K | 0-10 Bar (0-150 PSI) | M10 x 1 | N/A | N/A | N/A | N/A |

| VDO 360-081-029-008C | 0-5 Bar (0-72.5 PSI) | 1/4 – 18 NPTF | N/A | N/A | N/A | N/A |

| VDO 360-081-029-010K | 0-10 Bar (0-150 PSI) | M10 | N/A | N/A | N/A | N/A |

| VDO 360-081-029-013C | 0-10 Bar (0-145 PSI) | M12 x 1.5 | 30 Bar (short duration) | -25°C to +100°C | 6 – 24 V DC | Optional |

| VDO 360-081-029-020C | 0-10 Bar (0-145 PSI) | 1/4 – 18 NPTF | 30 Bar (short duration) | -25°C to +100°C | 6 – 24 V DC | Optional |

These sensors ensure that marine equipment operates efficiently and safely, even in harsh conditions.

Key Selection Criteria for Pressure Sensors

Measurement Range

Selecting the appropriate measurement range is crucial for effective pressure sensor performance. Hydraulic systems often operate under varying pressure conditions, necessitating sensors that can accurately measure these fluctuations. For high-pressure hydraulic systems, sensors typically require a measurement range above 6000 psi. Some advanced models, like the Mensor CPG2500, can measure pressures up to 42,000 psi.

| Sensor Type | Measurement Range |

|---|---|

| Digital Hydraulic Pressure Gauge | Above 6000 psi (up to 42,000 psi for Mensor CPG2500, 15,000 psi for CPG1500) |

Additionally, the following ranges are common for hydraulic applications:

| Parameter | Range |

|---|---|

| Gauge, Hydraulic | (0 to 30,075) psig |

| Absolute, Hydraulic | (0 to 30,090) psia |

Accuracy Levels

Accuracy is another critical factor in selecting pressure sensors. High accuracy ensures reliable readings, which is vital for maintaining system integrity. Industry standards often dictate that hydraulic pressure sensors achieve accuracy levels of 0.008% or better. For instance, the CPG2500 Digital Hydraulic Pressure Indicator meets this standard, making it suitable for calibration labs and other precision applications.

| Feature | Details |

|---|---|

| Model | CPG2500 Digital Hydraulic Pressure Indicator |

| Accuracy | 0.008% IS-33 |

| Pressure Range | Up to 42,000 psi |

| Operating Temperature Range | 15 to 40 deg C |

| Communication Interfaces | Ethernet, IEEE-488, USB, RS-232 |

| Applications | Calibration lab, Transfer standard with remote transducers, Simultaneous three channel monitoring |

Environmental Conditions

Environmental factors significantly influence sensor performance. When selecting a pressure sensor, consider the following conditions:

- Temperature

- Humidity

- Exposure to corrosive or hazardous substances

These factors can affect the sensor’s accuracy and lifespan. Therefore, choosing a sensor designed to withstand specific environmental challenges is essential for ensuring long-term reliability.

Durability and Material Selection

Durability is paramount in hydraulic systems, where sensors often face harsh conditions. Selecting the right materials can enhance a sensor’s resistance to wear, corrosion, and pressure fluctuations. Common materials include stainless steel and specialized alloys, which provide excellent durability. Additionally, sensors should have protective coatings or enclosures to shield them from environmental hazards.

Calibration and Maintenance Needs

Regular calibration and maintenance are vital for maintaining sensor accuracy. Some sensors require frequent recalibration, while others may have built-in self-calibration features. Understanding the maintenance requirements of a sensor can help operators plan for downtime and ensure consistent performance.

Tip: Always consult the manufacturer’s guidelines for calibration intervals and maintenance procedures to maximize sensor lifespan and reliability.

Common Challenges in Selecting Pressure Sensors

Compatibility with Existing Systems

Selecting a pressure sensor that integrates seamlessly with existing hydraulic systems poses a significant challenge. To mitigate compatibility issues, consider the following factors:

- Measurement Range: Ensure the sensor can accurately measure the expected pressure levels for your application.

- Accuracy and Precision: Choose high-precision sensors for critical applications, while lower accuracy may suffice for less demanding tasks.

- Environmental Conditions: Select a sensor designed to withstand temperature, humidity, and exposure to corrosive substances.

- Output Type: Ensure the sensor’s output is compatible with your system, whether analog or digital.

- Response Time: For dynamic applications, prioritize sensors with faster response times to monitor rapid pressure changes.

- Size and Mounting: Confirm that the sensor’s size and mounting options fit your application requirements.

Cost vs. Performance Trade-offs

Balancing cost and performance remains a common dilemma. While high-performance sensors often come with a higher price tag, they may provide long-term savings through enhanced reliability and reduced maintenance costs. Operators should evaluate the specific needs of their hydraulic systems to determine the most suitable option.

Supplier Reliability

Choosing a reliable supplier is crucial for ensuring the quality and longevity of pressure sensors. A reputable supplier offers not only high-quality products but also support services, including installation guidance and maintenance assistance. Researching supplier reviews and industry reputation can help operators make informed decisions.

Tip: Always verify the supplier’s warranty and support policies before making a purchase to ensure a smooth experience.

Selecting the right pressure sensor significantly impacts hydraulic system performance. Key factors include accuracy, durability, and environmental adaptability. Informed decisions lead to benefits such as real-time data, reduced failure risks, and precise pressure control. Prioritizing these elements ensures optimal efficiency and reliability in hydraulic operations.

FAQ

What factors affect the accuracy of a pressure sensor?

Temperature, humidity, and environmental exposure significantly impact a sensor’s accuracy. Selecting a sensor designed for specific conditions ensures reliable performance.

How often should pressure sensors be calibrated?

Calibration frequency depends on the sensor type and application. Regular checks help maintain accuracy and reliability in hydraulic systems.

Can pressure sensors be used in extreme environments?

Yes, specialized sensors can operate in extreme conditions. Selecting durable materials and protective coatings enhances their performance in harsh environments.

Post time: Jan-29-2026