The integration of IIoT and solenoid valves fundamentally transforms industrial operations. This shift moves beyond simple automation. It enables predictive maintenance, real-time control, and enhanced efficiency. This lays the groundwork for truly smart factories. The IoT in Manufacturing Market was valued at USD 116.52 billion in 2024, underscoring this sector’s significant growth. This advancement ensures optimal performance for components such as the Solenoid Valve Core 39741-18K.

Key Takeaways

- IIoT connects industrial devices. It helps factories run better. Solenoid valves work with IIoT. This makes them smarter.

- IIoT helps fix solenoid valves before they break. This saves money. It also keeps factories running without stopping.

- IIoT makes factories safer. It helps them use less energy. This is good for the environment and saves money.

Understanding IIoT and Solenoid Valves

What is Industrial IoT?

Industrial IoT (IIoT) connects industrial devices, equipment, and systems. It uses sensors, software, and other technologies to gather and analyze data. This creates a network of interconnected machines. A typical IIoT system includes several key components. PLC devices and IoT sensors on machines emit telemetry data. A Redpanda cluster handles telemetry data ingestion. An Apache Flink® cluster performs stateful stream processing. Machine learning models conduct predictive analysis. A time series database monitors equipment. Workflow engines trigger automated business workflows. Data lakes and warehouses store cold industrial data. Line of Business (LoB) applications integrate internal business systems.

The shift towards data-focused manufacturing in IIoT relies on three pillars. First, connectivity links industrial devices and systems for real-time data communication. Second, data collection and analysis use advanced tools to extract insights. This optimizes processes and supports data-driven decisions. Third, automation and control connect sensors and actuators to control systems. This leads to efficient and precise control of industrial processes. Most IoT architectures share four major components. These include a security and management component, an applications and analytics component, an infrastructure component, and an integration component.

The Critical Role of Solenoid Valves

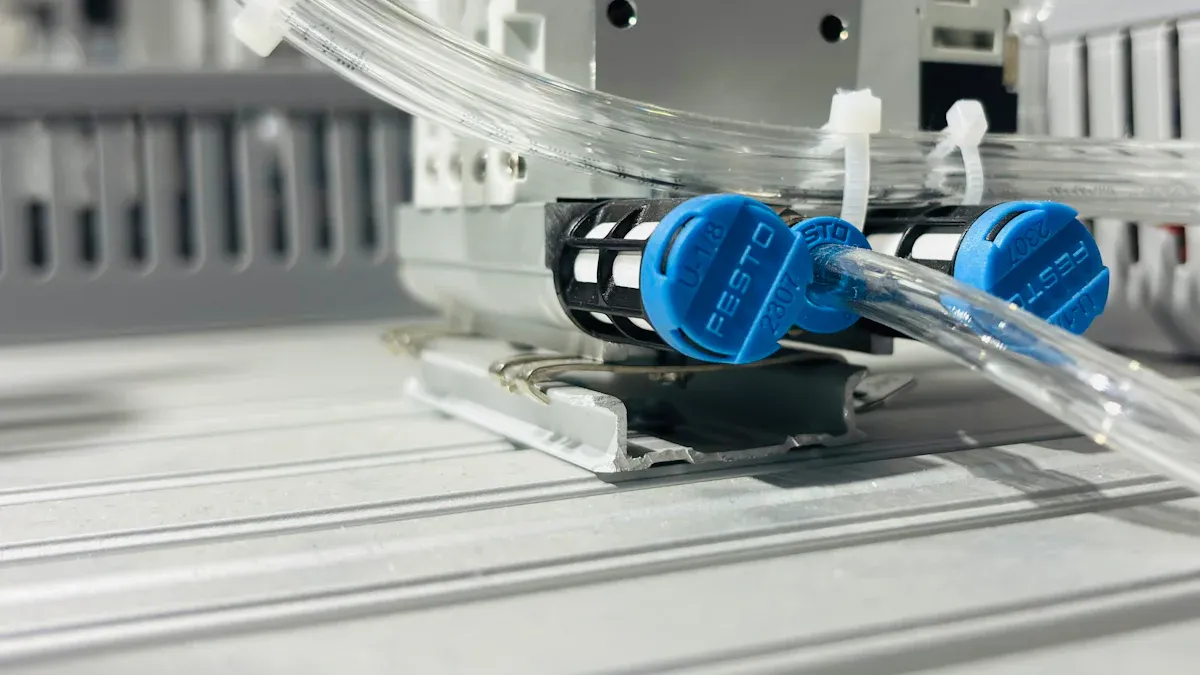

A solenoid valve is an electromechanical device. It regulates fluid flow. It consists of an electromagnetic actuator and a valve body. The solenoid-plunger assembly opens and closes the valve. It operates in a binary mode, either fully open or fully closed. The solenoid converts electrical energy into mechanical motion. This happens through a push-and-pull action. When electrical current flows through a wire coil, it generates a magnetic field. This actuates a ferromagnetic plug or plunger. Proportional solenoid valves offer continuous modulation of flow or pressure. They function as control valves. The plunger’s position is adjustable. Changes in electrical current modify the electromagnetic force. This adjusts the spring’s compression or extension. This allows precise flow and pressure control. Solenoid valves are crucial in industrial automation. They regulate the flow of air, gas, water, and oil. This ensures process efficiency and safety. They control compressed air and fluids in manufacturing equipment. For example, the Solenoid Valve Core 39741-18K is a vital component in many such systems. These valves are also vital for regulating compressed air flow in pneumatic systems. They enable precise activation of pneumatic actuators. In fluid power hydraulic systems, solenoid valves regulate hydraulic fluid. They control power transmission and ensure safe machinery operation.

IIoT’s Impact on Solenoid Valve Performance

The integration of IIoT fundamentally transforms how industries manage and optimize solenoid valves. This advanced connectivity moves beyond simple on/off functions, enabling a new era of intelligent operation, predictive insights, and unparalleled efficiency.

Real-time Monitoring and Data Insights

IIoT empowers industries with real-time monitoring capabilities for solenoid valves, providing immediate access to critical operational data. Sensors attached to valves continuously collect information on parameters such as pressure, temperature, flow rates, and operational cycles. This constant stream of data offers deep insights into valve performance and overall system health.

“Having a remote monitoring system means we don’t have to worry as much about valve failures. With more—and better—information, we can order parts in advance, schedule repairs, and limit unexpected downtime.” — Dan Morris, Valve Technician, City of Ames Electric

Valve condition monitoring significantly optimizes outages, improves plant sustainability, and predicts maintenance events. It helps identify valve-related problems such as valve spring failures, stuck valves, and valve packing leaks. This proactive approach allows for less time spent on valves by enabling a predictive maintenance strategy.

IIoT sensors support the Modbus protocol, enabling real-time online monitoring, analysis, and reporting. They offer remote cloud security and visual management, providing a comprehensive overview of operations. These sensors deliver 24/7 monitoring of critical equipment, replacing periodic manual checks and significantly reducing labor costs in equipment monitoring. They can also trigger less expensive preventive maintenance tasks, which helps reduce major problems or emergency repairs. Sensor data integrates with Computerized Maintenance Management Systems (CMMS) for analysis, allowing maintenance managers to examine historical trends, pinpoint failure spots, and make better future business decisions.

The process of leveraging IIoT sensors for data insights typically follows a structured flow:

- IIoT Sensors: These devices collect raw data from the solenoid valves and their surrounding environment.

- Data Transmission: The collected data transmits securely to the cloud or local servers.

- Storage Data: Systems store and analyze this data, often in specialized databases designed for time-series information.

- Predictive Analysis: Based on the analysis of new and historical data, often utilizing AI and machine learning techniques, systems make predictive maintenance decisions for equipment.

Predictive Maintenance for Solenoid Valve Core 39741-18K

Predictive maintenance, powered by IIoT, represents a significant leap from traditional reactive or time-based maintenance. By continuously monitoring the operational parameters of solenoid valves, systems can anticipate potential failures before they occur. This capability is particularly crucial for components like the Solenoid Valve Core 39741-18K, where unexpected failure can halt production.

Common failure modes of solenoid valves that predictive maintenance effectively addresses include:

- Electrical Component (Coil) Failures:

- Incorrect voltage or frequency application, leading to coil burnout or damage.

- Electrical spikes from the power source, causing irreparable damage to coils.

- Water ingress or liquid contamination, especially if the IP rating is insufficient for the environment.

- Debris, sediment, or particle contamination limiting armature motion, causing the coil to overheat.

- Irregular valve response time, indicating a malfunctioning or damaged solenoid coil.

- Mechanical Component (Valve) Failures:

- Exceeding the pressure rating, resulting in diaphragm tears or damage to the valve body and armature tube assembly.

- Exceeding the temperature rating (media or ambient), leading to deformation or discoloration of diaphragms, seals, and o-rings.

- External contamination by sediment or particles, affecting normal operation, response time, and causing leaks or incomplete sealing.

- Corrosion of metallic components or degradation of seals and diaphragms due to incompatibility with flow media or internal contamination.

Predictive maintenance significantly reduces unplanned downtime. Early adopters of Google’s AI-powered maintenance scheduling system, which includes solenoid valves, have reported a 50% decrease in unexpected failures. Proactive replacement of worn solenoid valves, such as the Solenoid Valve Core 39741-18K, can lead to a reduction in unplanned downtime ranging from 30% to 50%. This proactive approach ensures the continuous operation of critical systems.

Enhanced Control and Process Optimization

IIoT-enabled solenoid valves contribute to more precise control by integrating into an interconnected ecosystem. This allows for real-time aggregation and analysis of data from various sensors and devices. Artificial Intelligence (AI) then utilizes self-learning models to meticulously examine how different valve operations influence fluid control and their impact on emissions. This real-time data and AI analysis enable the identification of valve failures and emission levels. It can even propose advanced valve designs for improved leak prevention, emission control, and energy optimization, ultimately leading to more precise and effective process management.

Process optimization achieved through IIoT integration with solenoid valves includes:

- Enhanced Energy Efficiency: Smart systems analyze operational data and adjust valve operations to maximize efficiency. Predictive maintenance algorithms identify inefficiencies in valve performance before significant energy losses occur, enabling timely interventions.

- Autonomous Adjustments: Integration with IIoT allows for remote monitoring, control, and autonomous decision-making based on data from multiple sources, enhancing overall system intelligence and adaptability. This includes real-time adjustments of fluid flow rates, pressure, and temperature.

- Predictive Maintenance: IIoT integration enhances predictive maintenance capabilities by allowing real-time data collection and analysis of valve operations. This helps anticipate and prevent potential failures, improving system reliability and uptime.

Leading manufacturers demonstrate the power of this integration:

| Manufacturer | Solenoid Valve Technology | Key Features of IIoT Integration | Process Optimization Achieved |

|---|---|---|---|

| Eaton | AxisPro® proportional valves | Closed-loop control, onboard electronics, sensors, microprocessors, communication via EtherNet/IP and PROFINET | Precise, dynamic flow control; continuous monitoring and adjustment of fluid flow, pressure, temperature; autonomous response to changing conditions; optimized performance and energy efficiency |

| Bosch | Rexroth 4WRPEH series high-response valves | Integrated digital electronics, closed-loop control, advanced spool position control, pressure sensors, OPC UA communication protocols | Precise and dynamic regulation of flow and pressure; real-time adjustments based on process feedback; predictive maintenance using valve performance data to prevent failures, enhancing reliability and uptime |

Driving Energy Efficiency and Resource Management

IIoT systems, integrating solenoid valves, enable real-time monitoring, control, and optimization of fluid and gas flow processes. This leads to smarter and more responsive production environments. Solenoid valves, equipped with sensors and connected to industrial networks, continuously collect data on their status, flow rates, and system performance. This data is then analyzed for informed decision-making.

IoT-enabled solenoid valves facilitate predictive maintenance by monitoring performance and wear patterns. This allows manufacturers to anticipate failures and schedule maintenance proactively, minimizing downtime and optimizing resource allocation. Dynamic resource allocation is achieved through remote control of solenoid valves, adjusting flow rates or redirecting resources based on real-time production demands. This enhances flexibility and reduces waste.

Advanced analytics and machine learning applications, leveraging historical and current data, optimize valve operations for energy efficiency, process consistency, and product quality. This drives continuous improvement in resource utilization. Robust cybersecurity measures are crucial for protecting these connected systems from unauthorized access or manipulation. Integration with IIoT systems also improves supply chain management by providing accurate, real-time data on resource consumption and production rates, leading to better coordination with suppliers and more precise inventory management. This comprehensive approach ensures that every Solenoid Valve Core 39741-18K and similar components contribute to an optimized and sustainable operation.

Tangible Benefits for Smarter Factories

The integration of IIoT with solenoid valves delivers concrete advantages for modern factories. These benefits extend across various operational aspects, creating more efficient, reliable, and intelligent manufacturing environments.

Boosting Uptime and Productivity

IIoT significantly enhances factory uptime and productivity by transforming how facilities manage equipment. The integration of smart sensors and IoT technologies enables real-time monitoring and optimization of solenoid valve performance. Operators collect and analyze data on valve operation, energy consumption, and process efficiency. This allows them to identify opportunities for energy savings and implement data-driven control strategies. Intelligent scheduling and predictive maintenance strategies optimize valve operation. They prevent energy waste due to wear or malfunction and reduce downtime. Advanced sensors, actuators, and control systems facilitate real-time monitoring, predictive maintenance, and adaptive process control. This leads to improved Overall Equipment Effectiveness (OEE) and reduced downtime for solenoid valves.

OEE serves as a key performance indicator, measuring how effectively a plant operates. It uses three factors: Availability, Quality, and Performance. IIoT involves networking devices in an industrial environment, connecting sensors to PLCs or directly to networks via IO-Link masters to collect and utilize data. IIoT integration allows systems to directly query sensor data for OEE calculation, bypassing the PLC. This offers particular advantages for older systems or when retrofitting sensors. For example, in a filling plant, IO-Link sensors provide a ‘quality-of-run’ value. This indicates process quality and the need for cleaning. It enables early and proactive responses to issues like dust accumulation on reflectors. This proactive approach prevents misbehavior and unplanned downtime, directly contributing to improved OEE. IIoT networking allows querying diagnostic data from sensors and actuators via REST API. This offers insights beyond simple switching signals, such as measured values and settings. The independence from PLCs in data acquisition means even old plants can benefit from OEE determination and predictive maintenance by retrofitting IO-Link sensors.

Reducing Operational Costs

The shift to IIoT-enabled solenoid valves directly translates into substantial reductions in operational costs. Predictive maintenance, a cornerstone of IIoT, minimizes unexpected equipment failures. This eliminates the high costs associated with emergency repairs, expedited parts shipping, and production halts. By anticipating maintenance needs, factories can schedule interventions during planned downtime, optimizing labor and resource allocation. Furthermore, the real-time monitoring of energy consumption by solenoid valves allows for precise adjustments. This ensures they operate at peak efficiency, reducing energy waste. Optimized fluid and gas flow, achieved through IIoT control, also lowers material consumption and minimizes waste. This comprehensive approach to efficiency and proactive maintenance significantly lowers the total cost of ownership for industrial equipment, including critical components like the Solenoid Valve Core 39741-18K.

Improving Safety and Compliance

IIoT systems significantly enhance safety protocols related to solenoid valve operations. Real-time monitoring enables remote tracking of critical variables. These include system pressure, flow rates, sealing efficiency, and media leakage rates in solenoid valves. This reduces the necessity for manual inspections in dangerous environments. It thereby lowers personnel exposure to hazards. Predictive maintenance continuously monitors valve performance through embedded sensors. It identifies anomalies that could compromise valve safety and reliability. This data facilitates the creation of effective predictive maintenance schedules. It allows for timely interventions or planned shutdowns before failures occur.

IIoT also centralizes data on solenoid valve performance. This offers insights into operational aspects. While primarily mentioned for energy efficiency and emission reduction, this centralized data indirectly supports safety. It identifies operational inefficiencies that might lead to unsafe conditions. Position feedback systems integrate IIoT sensors to monitor the real-time status of solenoid valves. These systems trigger safety alerts when operational conditions exceed predefined safety limits. They work in conjunction with emergency shutdown systems to automatically halt processes during elevated hazards. This proactive and data-driven approach ensures factories maintain high safety standards and comply with regulatory requirements.

Enabling Data-Driven Decisions

IIoT insights from solenoid valves empower factories to make truly data-driven decisions. Real-time operational data, collected from sensors, feeds into analytics and machine learning platforms. These platforms identify patterns and trends. This allows maintenance to be scheduled based on actual performance rather than fixed intervals. This approach reduces downtime and extends valve lifespan. The integration of sensors and smart technologies into these valves provides data on flow rates, pressure, temperature, and valve position. This information is crucial for predictive maintenance and improving overall system efficiency. This data-driven approach also contributes to reducing downtime and improving overall equipment effectiveness (OEE).

The wealth of data provided by IIoT supports more informed decision-making across the entire operation. It leads to enhanced operational efficiency and increased productivity. Continuous monitoring and predictive maintenance improve workplace safety and ensure compliance with regulatory standards. By monitoring and optimizing energy usage, IIoT contributes to greater energy efficiency and reduced environmental impact. Continuous monitoring and control over production processes result in higher quality products and fewer defects. Ultimately, IIoT enables businesses to respond faster to market changes and opportunities, fostering agility and competitiveness.

Key Implementation Considerations

Implementing IIoT solutions for solenoid valves requires careful planning. Organizations must address several critical factors to ensure successful integration and maximize benefits.

Addressing Data Security

Data security stands as a paramount concern for IIoT systems integrated with solenoid valves. Cyberattacks pose significant threats, including ransomware, malware, and Distributed Denial of Service (DDoS) attacks. These attacks can disrupt operations or steal sensitive data. Insider threats, whether intentional or accidental, also present risks. Device vulnerabilities, such as outdated firmware or weak authentication, create entry points for malicious actors. Furthermore, physical threats and environmental factors can compromise system integrity. Robust encryption, secure communication protocols, and stringent access controls are essential to protect these interconnected systems.

Ensuring System Interoperability

Interoperability presents a major challenge when integrating IIoT with existing industrial control systems. The industrial ecosystem features an exponential growth of heterogeneous technologies, devices, and standards. This fragmentation stems from widespread proprietary technologies and legacy systems. These older systems often lack the necessary digital outputs or communication protocols for modern IoT platforms. This leads to communication limitations and vendor lock-in. To overcome these issues, open standards and protocols are crucial. Protocols like MQTT, CoAP, and LoRaWAN facilitate compatibility across diverse hardware and software platforms, ensuring seamless data exchange.

Evaluating Investment and ROI

The initial capital investment for high-precision and advanced hydraulic solenoid valves, along with IIoT solutions, can be substantial. This often challenges small and medium-sized enterprises (SMEs) or projects with limited budgets. Organizations must conduct thorough cost-benefit analyses. They need a strong return on investment (ROI) justification to overcome this hurdle and accelerate adoption. This evaluation should consider long-term savings from predictive maintenance, energy efficiency, and increased productivity.

Bridging the Skill Gap

A significant obstacle to IIoT innovation and effective deployments is the shortage of skilled personnel. Organizations must develop unique talent strategies. They can acquire new capabilities or build them within their existing workforce. Resources like IoT School and AI School offer free training for common application patterns. Collaborating with expert service providers also helps bridge this gap.

“Our latest research shows that, despite strong levels of IoT adoption across the board, skills shortages continue to be the top barrier to industrial IoT adoption. It is particularly concerning to note that, amongst those organisations lacking specific skills, almost half are missing security, data science and connectivity technology skills.”

Low-code platforms can also simplify development and deployment, reducing the need for highly specialized skills.

The Future of IIoT and Solenoid Valves

Integrating AI and Machine Learning

The future of IIoT-enabled solenoid valves heavily relies on Artificial Intelligence (AI) and Machine Learning (ML). These technologies enhance predictive maintenance (PdM) by anticipating failures. AI-driven PdM systems analyze data from sensors and historical records. They detect early signs of wear, leaks, blockages, or other valve malfunctions. This real-time sensor monitoring covers various system conditions:

- Flow rate: Unusual rates signal valve or actuator issues, blockages, or pump malfunctions.

- Pressure: Sudden drops indicate pipe bursts or stuck valves; increases point to blockages.

- Temperature: Overheating actuators suggest motor wear or restricted valve components.

- Vibration & Acoustic Analysis: AI detects unusual vibrations, indicating mechanical degradation like a damaged valve seat.

- Torque & Position Feedback: Deviations in expected movement signify buildup or misalignment; increased torque often indicates a problem within the valve.

AI and ML also enable valve automatic diagnostics. They continuously monitor critical valves using AI-powered analytics. This helps maintenance teams focus on the worst-performing valves. Machine learning models estimate valve lifecycles and recommend optimal service times, improving reliability. A novel AI algorithm considers service demand forecasts, installed base, parts availability, and customer maintenance strategies. This recommends optimal spare parts and device inventory.

Leveraging Edge Computing

Edge computing plays a crucial role in processing data from IIoT-connected solenoid valves. End-users seek IoT solutions that integrate seamlessly with existing industrial control systems. They also demand advanced analytics and user-friendly interfaces. There is a growing need for edge computing solutions. These solutions process valve performance data locally. This reduces latency and improves real-time decision-making capabilities. IBM’s Watson IoT platform uses edge computing for immediate data processing. This reduces latency and enables quick responses to potential issues. Hitachi’s Lumada IoT platform also uses edge computing devices for initial data processing and anomaly detection. This reduces data transmission loads and allows for rapid responses to critical issues.

Expanding Ecosystem Integration

Emerging trends in ecosystem integration for IIoT and solenoid valve technologies include enhanced data analytics and improved cybersecurity. They also incorporate AI for autonomous system optimization. These advancements solidify the role of solenoid valves as critical components in smart factories. Smart solenoid valves integrate with sensors to monitor parameters like pressure, temperature, and flow rate. They transmit this data to central control systems for remote monitoring and control. This integration enables predictive maintenance strategies and dynamic control strategies. It also allows seamless coordination with other smart devices in manufacturing environments, such as compressors and dryers. The market shifts towards smart and connected systems. This involves integrating IoT technologies and advanced sensors for real-time monitoring and predictive maintenance. Industries prioritize valves that perform reliably and provide actionable data through embedded sensors and connectivity. This enhances process transparency and decision-making accuracy.

The integration of IIoT with solenoid valves fundamentally transforms industrial operations. It creates more efficient, reliable, and intelligent industrial environments. Adopting these advanced technologies is crucial for industries. This ensures they remain competitive and thrive in the evolving manufacturing landscape.

FAQ

What is the primary benefit of integrating IIoT with solenoid valves?

Integrating IIoT with solenoid valves primarily enables predictive maintenance and real-time control. This leads to enhanced efficiency and reduced downtime in industrial operations.

How does IIoT assist with solenoid valve maintenance?

IIoT sensors continuously monitor valve performance data. This allows systems to anticipate potential failures. Factories can then schedule maintenance proactively, preventing unexpected breakdowns.

Can IIoT improve energy efficiency for solenoid valves?

Yes, IIoT systems analyze operational data. They adjust valve operations to maximize efficiency. This reduces energy waste and optimizes resource allocation for smarter factories.

Post time: Nov-05-2025