Understanding Solenoid Coil protection ratings ensures equipment longevity and safety. Unprotected devices face significant risks. High ambient temperatures can cause insulation to age, leading to short circuits. Poor heat dissipation also causes burnout. These ratings prevent such failures, ensuring reliable operation in various environments.

Key Takeaways

- IP ratings show how well a solenoid coil protects against dust and water. A higher number means better protection.

- ATEX ratings ensure solenoid coils are safe to use where explosions might happen. They prevent the coil from causing a spark or getting too hot.

- Both IP and ATEX ratings are important. IP protects from outside elements, and ATEX protects from explosions. You need to pick the right ratings for your coil’s environment.

Decoding IP Ratings for Solenoid Coils

What IP Ratings Indicate for Solenoid Coils

IP ratings, or Ingress Protection ratings, tell users how well an electrical enclosure protects against solids and liquids. The International Electrotechnical Commission (IEC) created the IP rating system under the IEC 60529 standard. This standard provides a clear way to classify the protection levels of electrical equipment. Manufacturers use these ratings to show a product’s resistance to dust, dirt, and water. A higher IP number means better protection.

First Digit: Solid Particle Protection for Solenoid Coils

The first digit in an IP rating describes the protection level against solid foreign objects. These objects include dust, dirt, and even fingers. The scale ranges from 0 to 6. A 0 means no protection. A 1 protects against large body parts like hands. A 4 protects against small tools or wires. A 6 offers complete protection against dust. This means no dust can enter the enclosure. For example, a Solenoid Coil with a first digit of 6 resists all dust.

Second Digit: Liquid Ingress Protection for Solenoid Coils

The second digit in an IP rating indicates the protection level against liquids, specifically water. This scale ranges from 0 to 9K. A 0 means no protection from water. A 1 protects against vertically dripping water. A 4 protects against water splashes from any direction. A 7 means the enclosure can withstand temporary immersion in water. For an IPX7 rating, the test involves a 30-minute immersion tank test. The lowest point of the enclosure must be 1 meter below the water surface in still water. After the test, inspectors check the product for any water inside and ensure it still works correctly. An 8 indicates protection against continuous immersion.

Common IP Ratings for Solenoid Coils

Different applications require different IP ratings. For many outdoor industrial applications, an IP67 rating is often recommended for solenoid valve coils. This rating provides complete dust protection and allows for temporary water immersion. Other common ratings include:

- IP65: This rating is typical for many solenoid valves in the European community. It protects against dust and water jets.

- IP54: This rating suits outdoor use. It protects against falling dirt, rain, sleet, snow, and windblown dust. External ice formation does not damage it. It also protects against limited dust ingress and water sprayed from all directions.

- IP56: This rating also suits outdoor use. It protects against falling dirt, rain, sleet, snow, windblown dust, splashing water, and hose-directed water. External ice formation does not damage it. It offers protection against limited dust ingress and strong jets of water from all directions.

ATEX Ratings for Hazardous Solenoid Coil Environments

The Purpose of ATEX Certification for Solenoid Coils

ATEX certification is a European Union directive. It outlines requirements for equipment and protective systems. These systems operate in potentially explosive atmospheres. This certification ensures products meet specific safety standards. It prevents explosion risks.

ATEX certification guarantees that a component is safe to use in areas where an explosive atmosphere may occur.

ATEX certification means a product underwent rigorous testing. It meets safety requirements for use in explosive atmospheres. It aims to reduce ignition sources. It promotes safety where flammable gases, vapors, liquids, or combustible dusts exist. Overall, ATEX certification enhances safety measures. It reduces incident likelihood in industries with explosive atmospheres. It assures equipment safety in these environments. This promotes a safer work environment for everyone involved. The aim of Directive 2014/34/EU is to allow free trade of ‘ATEX’ equipment and protective systems within the EU. It removes the need for separate testing and documentation for each Member State.

ATEX Equipment Groups and Categories for Solenoid Coils

Two main ATEX directives govern equipment and protective systems.

- The ATEX 114 "equipment" Directive 2014/34/EU covers equipment and protective systems for potentially explosive atmospheres.

- The ATEX 153 "workplace" Directive 1999/92/EC sets minimum requirements for improving worker safety and health protection. These workers are potentially at risk from explosive atmospheres.

The ATEX Workplace Directive (1999/92/EC) focuses on worker safety. It outlines employer obligations. These include explosion risk assessments, hazardous area classification, and prevention measures. It also requires an explosion protection document. The ATEX Product Directive (2014/34/EU) applies to equipment. Manufacturers must design products to prevent explosive atmospheres. They must avoid ignition sources. If an explosion occurs, the product must limit its consequences to a safe level.

ATEX classifies equipment into groups and categories. Group I equipment is for mining. Group II equipment is for all other surface industries. Categories within these groups define the protection level.

For Group I, categories are M1 and M2.

- Equipment in ATEX Group I Category M1 is for mining use. It must remain functional even when an explosive atmosphere is present.

- When one integrated measure fails, a second measure provides a sufficient level of safety.

- A sufficient level of safety is provided when two faults happen independently.

- It remains functional even in rare incidents with an explosive atmosphere present.

- Either, if one protection means fails, an independent second means provides the necessary protection.

- Or, the necessary protection is assured if faults occur independently of each other.

For Group II, categories are 1, 2, and 3. Category 1 offers the highest protection. Category 3 offers the lowest.

Solenoid Coil Protection Types in ATEX Environments

Manufacturers use various protection methods for solenoid coils in ATEX environments. These methods prevent ignition of hazardous atmospheres.

| Protection Method | Safety Performance | Implementation Complexity | Operational Impact | Total Cost of Ownership | Best Use Scenarios |

|---|---|---|---|---|---|

| Exm (Encapsulation) | High. Isolates ignition sources by potting them in resin, preventing atmospheric contact with sparking components. | Low. Self-contained component; installation similar to standard components with standard wiring. | Minimal. No special live maintenance; component is non-repairable, requiring replacement upon failure. | Low-Medium. Low initial installation, but replacement cost can be a factor. | Zone 1/2 applications for small components, subject to vibration, where repair is not a priority (e.g., small solenoid coils, sensors). |

| Exd (Flameproof) | High. Contains internal explosions and quenches flames, preventing ignition of external atmosphere. | Medium. Requires specific certified cable glands and conduits; flame path integrity must be maintained. | High. ‘Hot work’ permits needed for maintenance; enclosure must be opened, requiring area shutdown. | Medium-High. Higher initial component cost; maintenance is labor-intensive, causing process downtime. | Zone 1/2 applications for high-power equipment or where robust physical protection is needed (e.g., large motors, control panels, high-power valves). |

| Exia (Intrinsic Safety) | Very High. Prevents ignition by limiting circuit energy below combustible levels, even under fault conditions. The only method for Zone 0. | High. Requires full system design (DSD), including safety barrier, specific cabling, and detailed entity parameter calculations. | Low (for maintenance). Live maintenance possible without hot work permits. High (for performance). Limited power can restrict valve performance. | High. High design and engineering costs; specialized barriers needed. Lower maintenance downtime can offset costs long-term. | Zone 0/1/2 applications where atmosphere is continuously or frequently hazardous and live maintenance offers operational benefits. |

Ex m Encapsulation involves potting the solenoid valve coil in a resin compound. This prevents contact with potentially explosive atmospheres of gas or dust. This method also limits the surface temperature under normal working conditions. It often includes a thermal fuse as a safety device. For example, EExmIIT4 indicates a maximum surface temperature of +130°C before cutout. This protection suits Zone 1 and Zone 21 Category 2 environments.

Ex d Flameproof protection encloses the solenoid valve coil within a metal enclosure. This enclosure withstands internal explosions. It prevents their transmission to the surrounding explosive atmosphere. This enclosure also prevents the hazardous atmosphere from entering. Maintenance requires careful consideration. Opening the enclosure can expose potentially explosive gases or dusts. This method is for Zone 1 and Zone 21 Categories 2 environments. It adheres to standards like Cenelec Standard 50018 ExdIICT6.

Zone Classifications for Hazardous Solenoid Coil Areas

ATEX defines hazardous areas using zones. These zones indicate the likelihood and duration of an explosive atmosphere.

- Zone 0 (Gases/Vapors) / Zone 20 (Dusts): An explosive atmosphere is present continuously, for long periods, or frequently. This is the highest risk zone.

- Zone 1 (Gases/Vapors) / Zone 21 (Dusts): An explosive atmosphere is likely to occur occasionally during normal operation.

- Zone 2 (Gases/Vapors) / Zone 22 (Dusts): An explosive atmosphere is not likely to occur in normal operation. If it does, it will only persist for a short period.

Selecting the correct equipment for each zone is critical. It ensures safety and compliance.

Temperature Classes (T-Class) for Solenoid Coils

Equipment operating in hazardous areas must not become an ignition source. This includes its surface temperature. The T-Class (Temperature Class) specifies the maximum surface temperature an electrical component can reach. This temperature must always remain below the auto-ignition temperature of the surrounding explosive atmosphere.

| T-Class | Max Surface Temp (°C) |

|---|---|

| T1 | 450 |

| T2 | 300 |

| T3 | 200 |

| T4 | 135 |

| T5 | 100 |

| T6 | 85 |

For example, equipment with a T4 rating has a maximum surface temperature of 135°C. This means it is safe to use in an atmosphere where the ignition temperature of the gas or dust is higher than 135°C. Choosing the correct T-Class prevents thermal ignition.

Interpreting ATEX Markings on Solenoid Coils

Understanding the ATEX Code Structure for Solenoid Coils

ATEX markings provide essential information about equipment designed for hazardous areas. Manufacturers apply these codes directly to the product. The code structure follows a specific sequence. It details the equipment group, category, type of hazardous substance, protection type, gas group, temperature class, and equipment protection level. Understanding each part of this code ensures proper equipment selection and safe operation.

Practical Examples of ATEX Markings for Solenoid Coils

Consider a Solenoid Coil with the marking ‘II 2 G Ex db IIC T6 Gb’. This code provides a comprehensive safety profile. Each element conveys critical information:

- II: This denotes the equipment group. It indicates suitability for all areas except mines.

- 2: This represents the equipment category. It means the device is suitable for Zone 1 (gases) or Zone 21 (dusts). An explosive atmosphere is likely to occur occasionally in these zones.

- G: This specifies the type of hazardous substance, which is Gas.

- Ex: This indicates the equipment is protected against explosions.

- db: This signifies the protection type, specifically ‘flameproof’. The enclosure contains an internal explosion without igniting the external atmosphere.

- IIC: This refers to the gas group. It indicates suitability for atmospheres containing acetylene and hydrogen. These are the most easily ignitable gases.

- T6: This represents the temperature class. The maximum surface temperature of the equipment will not exceed 85°C.

- Gb: This denotes the equipment protection level (EPL). It indicates a high level of protection for gas atmospheres, suitable for Zone 1.

Common Misconceptions and Critical Considerations for Solenoid Coils

IP Ratings and Outdoor Suitability of Solenoid Coils

Many people believe a high IP rating, like IP67, guarantees full outdoor suitability for a Solenoid Coil. However, this is a misconception. IP ratings primarily indicate protection against dust and water ingress. They do not inherently shield against other environmental factors. For example, IP67 waterproof enclosures protect against dust and water, but they do not inherently shield against UV rays. Prolonged outdoor exposure requires additional UV-resistant materials to prevent degradation. The IP rating dictates protection against dust and water ingress, but it is not guaranteed protection against UV rays. Additional UV protection is necessary for electrical enclosures in areas visible to sunlight. Extreme temperatures, beyond the operational range of the component, also pose a risk not directly covered by IP ratings.

ATEX Protection Limitations for Solenoid Coils

ATEX certification specifically addresses the prevention of explosions in hazardous atmospheres. It ensures equipment does not become an ignition source. However, ATEX protection has limitations. It does not cover other environmental challenges like corrosion, extreme temperatures (beyond the specified T-class), or physical impact. These factors can still compromise equipment integrity and function. ATEX focuses on preventing ignition, not general durability or resistance to non-explosive environmental stressors. Users must consider these additional factors when selecting equipment for harsh environments.

The Interplay Between IP and ATEX for Solenoid Coils

IP and ATEX ratings address different, yet often complementary, aspects of equipment protection. IP ratings focus on ingress protection from solids and liquids. ATEX ratings focus on preventing ignition in potentially explosive atmospheres. In many industrial applications, equipment requires both. For instance, a device in a chemical plant might need an IP67 rating to protect against water jets and dust, and an ATEX certification to prevent explosions from flammable gases. Understanding this interplay is crucial for comprehensive safety and operational reliability.

Selecting the Right Protection Rating for Your Solenoid Coil

Assessing Environmental Conditions for Solenoid Coils

Choosing the correct protection rating for a Solenoid Coil begins with a thorough assessment of its operating environment. Engineers must consider factors beyond just dust and water. They evaluate ambient temperatures, humidity levels, and the presence of corrosive chemicals. Mechanical stress, such as vibration or impact, also plays a role. Understanding these conditions helps determine the necessary IP rating and material specifications for long-term reliability.

Identifying Hazardous Area Requirements for Solenoid Coils

Identifying hazardous area requirements is crucial for safety. These areas contain flammable substances that can ignite. ATEX certification is required for solenoid valves used in potentially explosive hazardous areas. This certification applies to the complete product, including both the coil and the body of the valve. This also extends to non-electrical equipment, such as filters, regulators, and other valves, if they are to be used within a zoned hazardous area. Specific criteria classify an area as hazardous:

- Class I: Locations where flammable gases and vapors are present, creating potentially explosive environments. An example is an oil refinery where volatile hydrocarbons release vapors.

- Class II: Areas dealing with combustible dust, such as those with dust traps or collectors, where airborne dust can explode upon ignition.

- Class III: Locations containing ignitable fibers or suspended materials, like textile mills, woodworking shops, and cotton gins.

Matching Solenoid Coil Rating to Application Needs

Matching the Solenoid Coil rating to application needs involves combining environmental assessments with hazardous area classifications. For non-hazardous environments, a suitable IP rating protects against ingress. For hazardous locations, the ATEX group, category, protection type, gas group, and temperature class must align with the zone classification. This ensures the equipment operates safely and reliably, preventing both operational failures and potential explosions.

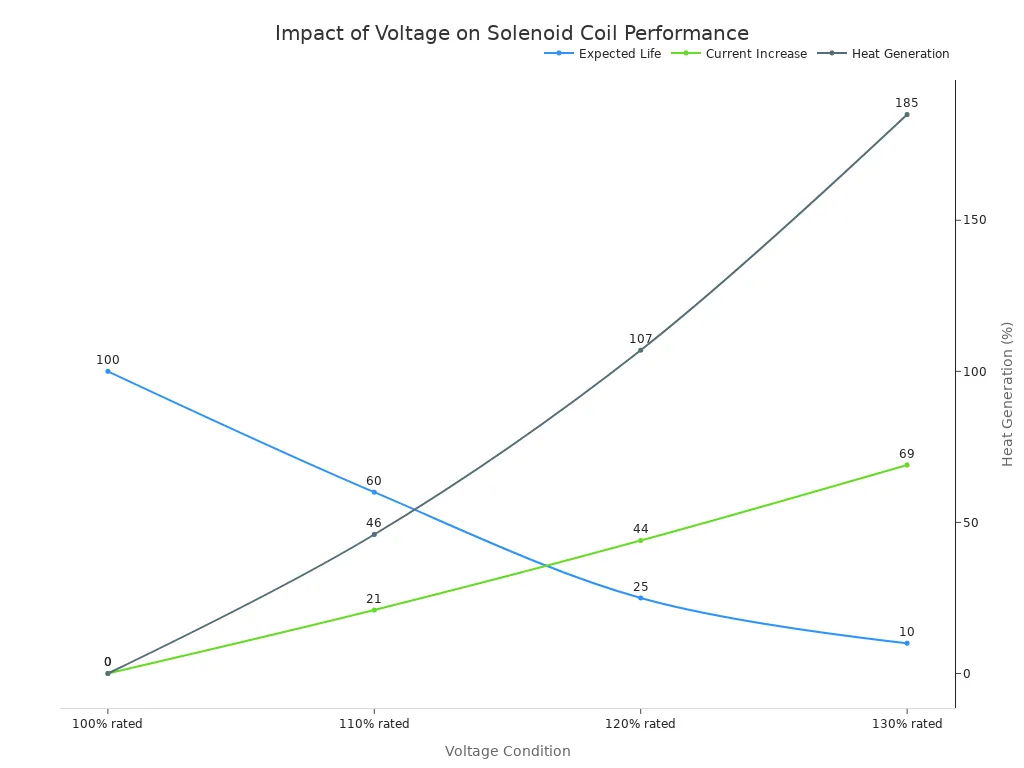

Proper Solenoid Coil protection ratings are vital for safety and operational reliability. Incorrect ratings, like overvoltage, drastically reduce expected life and increase heat, leading to premature failure and higher costs.

Matching ratings to environmental and hazardous area needs ensures long-term performance and prevents costly downtime.

FAQ

What is the main difference between IP and ATEX ratings?

IP ratings protect against solid and liquid ingress. ATEX ratings prevent explosions in hazardous atmospheres. They address different safety aspects for equipment.

Does a high IP rating mean a solenoid coil is ATEX compliant?

No. A high IP rating indicates protection from dust and water. ATEX certification specifically addresses explosion prevention. Both are often necessary for safety.

Why is the T-Class important for ATEX-certified solenoid coils?

The T-Class specifies the maximum surface temperature. It ensures the coil’s surface does not ignite the surrounding explosive atmosphere. This prevents thermal ignition.

Post time: Jan-07-2026