Durable Solenoid Valves are critical for operational integrity in demanding industrial settings. Robust Solenoid Valve solutions prevent failures. They ensure safety in extreme conditions. Companies require these components for continuous, reliable performance. This minimizes downtime and protects personnel.

Key Takeaways

- Durable solenoid valves are important for tough industrial places. They work well with strong chemicals, extreme heat, and high pressure. This keeps machines running and people safe.

- These strong valves save money over time. They break less often, so you spend less on repairs and new parts. This also means machines do not stop working as much.

- Special materials and designs make solenoid valves last longer. They use strong metals and seals that do not leak. This helps meet safety rules and keeps the environment clean.

Challenges for Solenoid Valves in Harsh Environments

Solenoid valves face numerous challenges in demanding industrial settings. These environments push components to their limits, requiring robust designs for reliable operation.

Corrosive Media and Chemical Exposure

Many industrial processes involve highly corrosive substances. These substances attack valve materials, leading to degradation and failure. Common corrosive media include strong acids like sulfuric acid, nitric acid, and hydrochloric acid. Alkalis and aggressive chemical solutions also pose significant threats. These chemicals, often found in pharmaceutical production, chemical reactions, and sewage treatment, demand valves constructed from resistant materials.

Extreme Temperatures and Pressures

Temperature extremes severely impact valve performance. Low temperatures, sometimes as low as -50°C, can cause coil freezing and make seals brittle, leading to cracks and leakage. High temperatures, exceeding 180°C in steam systems, cause coil burnout, melt seals, and induce thermal expansion in metal components. This expansion affects valve operation. High pressures, particularly in power plants managing high-energy steam, require specialized designs far beyond standard parts. Failure in such conditions leads to significant consequences.

Abrasive Contaminants and Mechanical Stress

Service fluids often contain abrasive particles. These particles cause steady mechanical wear on valve components. Excessive impurities in oil, for example, significantly aggravate the wear of the solenoid valve spool. Moisture, oil, and debris in compressed air lines also contribute to wear and tear, reducing valve lifespan and efficiency.

Hazardous and Explosive Atmospheres

Certain industrial environments contain flammable gases, vapors, or dust. These hazardous atmospheres present a high risk of explosion. Solenoid valves operating in these areas must prevent ignition sources. They require specialized designs and certifications to ensure safety and compliance with strict regulations.

What Makes Solenoid Valves Durable for Harsh Environments?

Durable solenoid valves are engineered with specific features and materials to withstand the most challenging industrial conditions. These design choices ensure longevity and reliable performance where standard valves would quickly fail.

Robust Material Selection for Solenoid Valves

Selecting the right materials is paramount for solenoid valve durability. Manufacturers choose materials based on their resistance to corrosion, temperature, pressure, and abrasion.

- Corrosion Resistance: For chemical processing, materials like PTFE (Polytetrafluoroethylene) offer exceptional resistance to acids, alkalis, and solvents. Manufacturers often use PTFE for valve bodies and diaphragms in highly aggressive applications. Stainless steel, particularly 316L, provides resistance to various chemicals, including acidic and chloride-rich media. It also remains unreactive to pharmaceutical and food-grade substances. Hastelloy, a nickel alloy, offers excellent corrosion resistance, handling high process temperatures and pressures. It defends against aggressive media corrosion, maintains stability at elevated temperatures, and resists pitting and crevice corrosion, especially with halides, alkaline, and acidic media. Non-metallic materials like Polyvinylidene Fluoride (PVDF) and Polyphenylene Sulphide (PPS) also provide excellent heat, abrasion, and chemical resistance, especially when working pressure and temperature are not excessively high.

- Temperature and Pressure Resistance: Stainless steel (304/316) offers excellent overall chemical resistance and is highly resistant to wear, temperature, and pressure. These materials can operate across a wide temperature range, from -196°C (-320°F) to 538°C (1000°F). Brass is a versatile and durable material suitable for neutral and non-corrosive media like water, compressed air, and oils. It withstands high temperatures. However, brass has modest corrosion resistance and is unsuitable for corrosive or acidic flow applications. The actual temperature and pressure limits for valves often depend on the seal material, the force required to open the valve at high pressures, and the actuator’s temperature resistance.

Advanced Sealing Technologies in Solenoid Valves

Sealing technologies are crucial for preventing leaks and maintaining operational integrity in harsh environments. Advanced seals ensure chemical compatibility and temperature stability.

- PTFE (Teflon): This material is resistant to almost all fluids and maintains stability over a wide temperature range, from -30 °C to 180 °C. PTFE wetted surface designs are ideal for semiconductor, pharmaceutical, biomedical, and chemical process applications. Manufacturers configure them with PTFE hard seats, FKM-Viton O-ring seats, or FFKM-Kalrez O-ring seats for unsurpassed chemical compatibility. An all-wetted PTFE body, valve stem, and one-piece diaphragm maintain an inert boundary for ultra-clean applications.

- Fluoroelastomers (FKM): Known for their resistance to aggressive chemicals, FKM (Viton) seals are very good overall. They resist oils, solvents (aliphatic, aromatic, halocarbons), acids, and animal/vegetable oils. FKM operates within a temperature range of -10 °C to 120 °C. However, FKM is not resistant to methanol, hot water/steam, polar solvents, certain esters/ethers, or glycol-based brake fluid. Engineers rely on seals that withstand environmental challenges, including extreme temperatures and high pressure. PTFE combines chemical resistance with structural stability to maintain functionality where traditional materials might fail, making it reliable in extreme operating conditions.

| Material | Chemical Resistance | Temperature Range |

|---|---|---|

| FKM (Viton) | Very good overall; resistant to oils, solvents (aliphatic, aromatic, halocarbons), acids, animal/vegetable oils. Not resistant to methanol, hot water/steam, polar solvents, certain esters/ethers, glycol-based brake fluid. | -10 °C to 120 °C |

| PTFE (Teflon) | Resistant to almost all fluids. | -30 °C to 180 °C |

Enhanced Coil and Enclosure Protection for Solenoid Valves

The coil and enclosure protect the valve’s electrical components from environmental damage. Enhanced protection ensures reliable operation in challenging conditions.

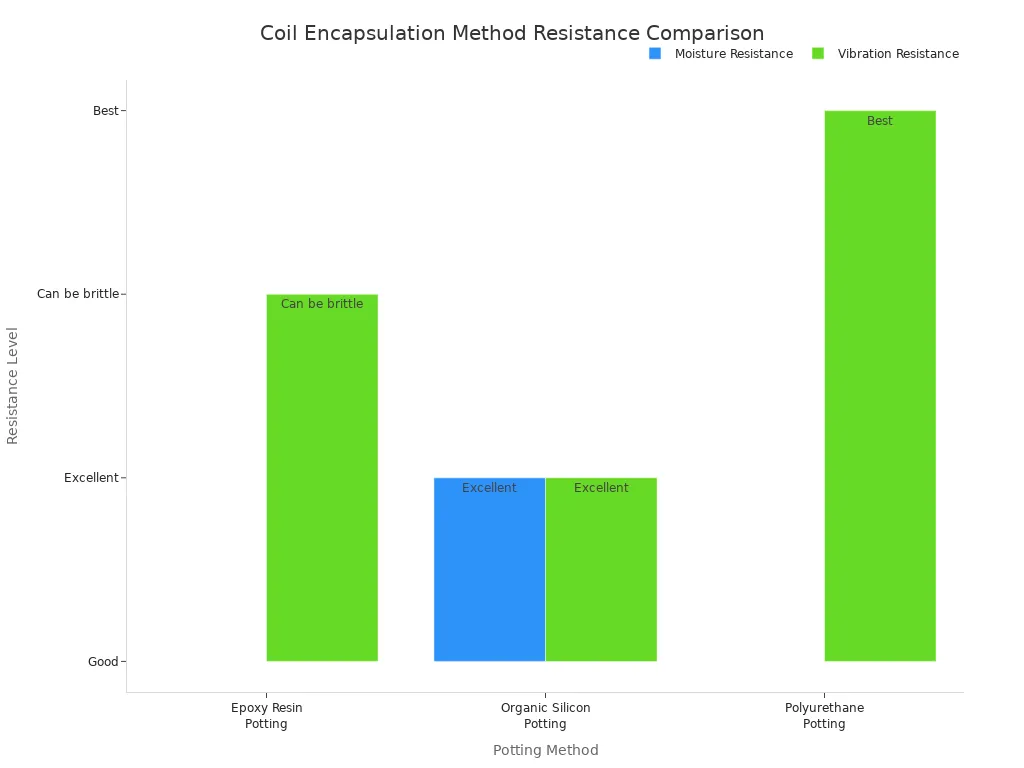

- Coil Encapsulation: Potting methods protect the coil from moisture, vibration, and temperature fluctuations.

- Epoxy Resin Potting: Offers good moisture resistance, high-temperature resistance, and electrical insulation. However, it can be brittle, leading to strain on components and potential cracks from thermal shock.

- Organic Silicon Potting: Provides excellent waterproof performance and superior shock resistance. It also boasts strong aging resistance, good weather resistance, and a wide operating temperature range (-60℃ ~ 200℃).

- Polyurethane Potting: Delivers the best anti-vibration performance, good water resistance, and anti-mould properties. It has good low-temperature resistance and elasticity.

- Enclosure Ratings: NEMA and IP ratings specify the level of protection against ingress of solids and liquids.

- NEMA 3: Suitable for indoor and outdoor use, offering strong protection against water and dust ingress, windblown dust, rain, sleet, and snow. Ice formation does not damage it.

- NEMA 4: Offers the same protection as NEMA 3 but adds protection against hose-directed water. This is popular for industrial plants like breweries and dairies where equipment undergoes washdown.

- NEMA 4X: Similar to NEMA 4, but includes additional protection against corrosion. This rating is frequently specified for outdoor and factory washdown environments.

- NEMA 6P: Provides protection against prolonged submersion to a limited depth (e.g., 6 feet for 24 hours) and includes corrosion protection. This is used in environments like mines and manholes where prolonged submersion might occur.

For outdoor applications, NEMA 3S to NEMA 4X or IP 54 to IP 64 ratings are essential. For situations involving occasional washdown or immersion, NEMA 6 and IP 68 ratings are necessary.

Specialized Construction for High-Pressure Solenoid Valves

High-pressure applications demand specialized valve construction to ensure safety and functionality. These valves feature robust bodies, reinforced internal components, and precise manufacturing tolerances. Designers often use direct-acting or internally piloted designs capable of handling extreme differential pressures without compromising seal integrity or operational speed. Materials like forged stainless steel provide the necessary strength and rigidity to prevent deformation under immense pressure.

Certifications for Hazardous Location Solenoid Valves

Operating in hazardous and explosive atmospheres requires specific certifications to prevent ignition. These certifications ensure the valve’s design and construction meet stringent safety standards.

- ATEX Certification: This European directive applies to equipment and protective systems intended for use in potentially explosive atmospheres. It categorizes equipment based on the level of protection required for different zones (e.g., Zone 0, 1, 2 for gases; Zone 20, 21, 22 for dust).

- IECEx Certification: An international certification scheme for equipment intended for use in explosive atmospheres. It facilitates international trade of equipment and services for use in such environments.

- UL/CSA Certifications: These North American certifications ensure electrical products meet safety standards, including those for hazardous locations (e.g., Class I, Division 1 or 2).

These certifications guarantee that the solenoid valve will not become an ignition source, protecting personnel and property in volatile environments.

Benefits of Durable Solenoid Valves in Critical Applications

Durable solenoid valves offer significant advantages in critical industrial settings. They ensure operational continuity, reduce costs, enhance safety, and improve overall system performance.

Maximized Operational Reliability and Uptime

Durable solenoid valves significantly boost operational reliability. They withstand harsh conditions, preventing unexpected failures. This resilience directly translates into increased uptime for industrial processes. For example, a Shortline operator achieved a 30% reduction in downtime. This improvement came from implementing durable solenoid valves in their irrigation systems. The reliable valve performance eliminated frequent disruptions. Industries rely on continuous operation. Therefore, these valves become indispensable. They ensure processes run smoothly without interruption.

Reduced Maintenance and Replacement Costs

Investing in durable solenoid valves leads to substantial cost savings over time. These valves require less frequent maintenance and replacement. This reduces labor costs and the expense of new parts. Energy-efficient solenoid valves can achieve a rapid return on investment within 2-3 years. This is primarily due to significant energy savings, up to 80% compared to traditional models, and reduced environmental impact.

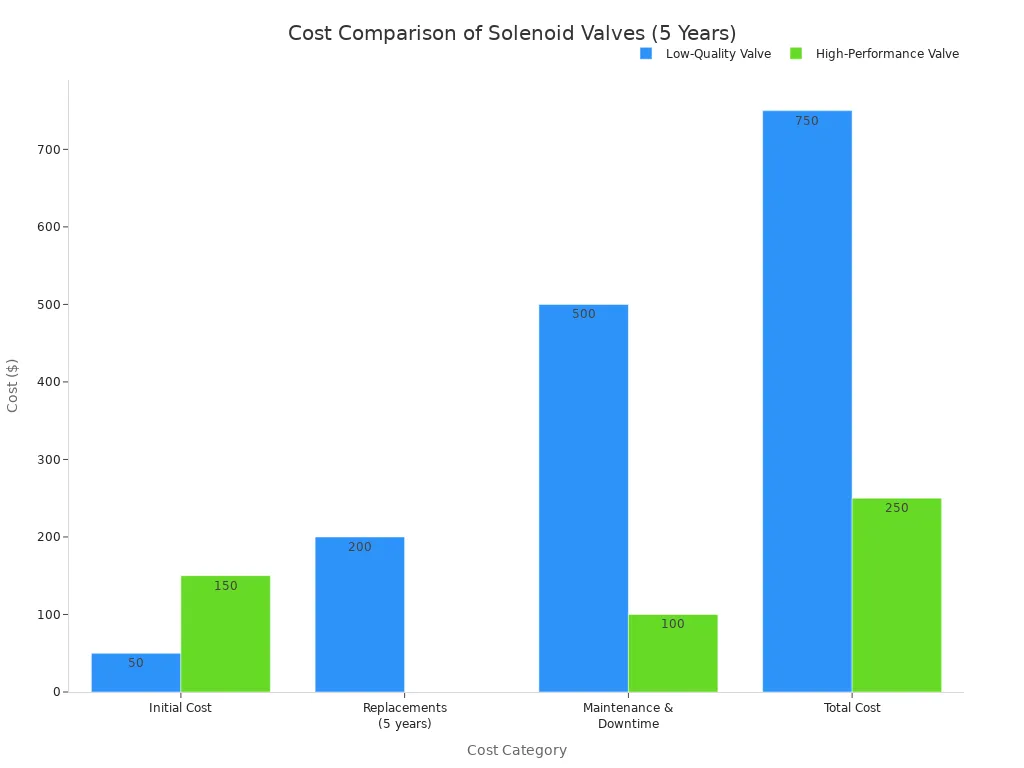

Consider the long-term cost comparison:

| Category | Low-Quality Valve | High-Performance Valve |

|---|---|---|

| Initial Cost | $50 | $150 |

| Replacements (5 years) | $200 | $0 |

| Maintenance & Downtime | $500 | $100 |

| Total Cost | $750 | $250 |

Investing in a high-performance valve results in savings of $500 over five years. This significantly reduces operational disruptions.

Enhanced Safety and Regulatory Compliance

Durable solenoid valves play a crucial role in maintaining safety and meeting regulatory standards. Solenoid valves certified for hazardous locations prevent several critical safety incidents. They are explosion-proof, directly mitigating explosion risks. Their intrinsically safe electrical circuits limit energy levels, preventing ignition in hazardous fluid applications. These valves minimize fugitive emissions and media leakages, which can cause fires or other hazardous situations. Robust materials resist corrosion and erosion, preventing structural degradation that could lead to leaks and safety issues.

Environmental regulations have significantly influenced the valve industry. This led to the development of more efficient and environmentally friendly products, particularly low-emission and zero-leakage valve designs. Manufacturers invested in advanced sealing technologies and materials to minimize leakage. This addresses concerns about fugitive emissions and regulatory non-compliance. Automated industrial valves are crucial for leak prevention and fugitive emissions control. They operate in a closed-loop environment, providing real-time feedback for continuous monitoring. They also offer quick responsiveness to control signals, including tight shut-off capabilities. This allows processes to promptly address leaks and fugitive emissions, preventing substantial releases of pollutants and greenhouse gases. These valves enable continuous evaluation of their integrity, facilitating timely maintenance or replacement to prevent chemical, fluid, or gas leakage. This supports cleaner operations in heavy industries. Zero leak solenoid valves help organizations meet increasingly stringent environmental compliance standards. They reduce the likelihood of leaks that could harm the environment.

Optimized System Performance and Efficiency

Durable solenoid valves contribute to optimized system performance and efficiency. Their precise control capabilities ensure accurate fluid and gas management. This leads to consistent process outcomes. Reliable operation minimizes waste and maximizes resource utilization. Smart valves with integrated sensors and control systems allow for real-time monitoring and precise control. This improves efficiency and helps companies meet environmental targets by reducing waste and energy consumption. Automated industrial valves collect extensive data throughout their operation. This data is vital for periodic audits and verifying compliance with minimum emission control standards. It also provides insights for process improvements to maintain emissions within acceptable levels, aligning with industry-specific regulations designed to combat pollution at its source.

Durable solenoid valves are essential for reliable operation in harsh environments. Investing in robust valve solutions mitigates risks. It also ensures continuous performance. The long-term value of these Solenoid Valves outweighs initial costs. They provide enhanced safety and efficiency.

FAQ

What defines a "harsh environment" for solenoid valves?

A harsh environment involves extreme conditions. These include corrosive chemicals, high temperatures, intense pressures, abrasive particles, or explosive atmospheres. These factors demand specialized valve designs.

Why are material choices so critical for durable solenoid valves?

Material selection directly impacts valve longevity. Resistant materials prevent corrosion, wear, and degradation. This ensures reliable operation and extends the valve’s service life in challenging conditions.

Post time: Oct-31-2025