Hydraulic cartridge valves enable precise, efficient, and compact control of hydraulic power. This control is essential for complex operations in confined spaces. They make modern mobile machinery functional and advanced. The global cartridge valve market was USD 1.49 billion in 2024. It projects to reach USD 1.99 billion by 2033, a 3.3% compound annual growth rate. This growth highlights the critical role of the Hydraulic Cartridge Valve.

Key Takeaways

- Hydraulic cartridge valves are small parts. They control fluid in machines. They make modern mobile machines work well.

- These valves offer many benefits. They save space and make machines work better. They also last a long time and are easy to fix.

- Cartridge valves help machines do complex tasks. They improve safety and save fuel. They are key to advanced machine control.

The Indispensable Role of Hydraulic Cartridge Valves

Defining Hydraulic Cartridge Valves

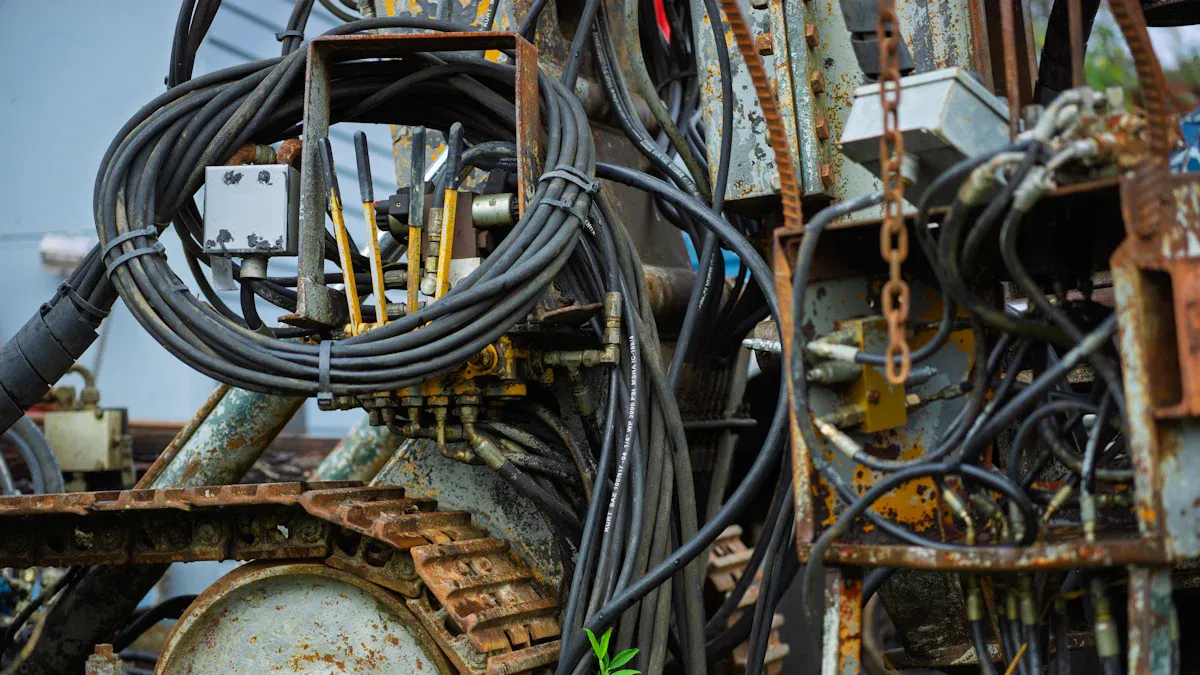

Hydraulic cartridge valves are compact, self-contained components. They control the flow, pressure, and direction of hydraulic fluid within a system. Engineers design these valves to fit into machined cavities within a manifold block. This integration creates a highly efficient and streamlined hydraulic circuit.

Why Hydraulic Cartridge Valves Are “Invisible”

These valves earn their “invisible” label due to their integrated design. Manufacturers seamlessly incorporate them into a single manifold block. This design significantly reduces external plumbing, complexity, and overall size. A basic cartridge valve consists of an insert that slips into a cavity. A control cover then bolts over it, securing it to the manifold. This compact design offers significant space-saving advantages, especially for applications with footprint concerns. It also results in fewer external leak points or components susceptible to damage, making the system cleaner and more robust.

Core Function of Precision Control

Precision control stands as a core function of the Hydraulic Cartridge Valve. Proportional valves, for instance, offer high accuracy and efficiency. They facilitate precise directional or flow control in both industrial and mobile hydraulic systems. These valves often integrate with automated electronic control units. This allows for exacting control. Proportional Reducing/Relieving Valves utilize patented metering technology for precise pressure regulation. These valves deliver stable performance across their operating range and handle high flow rates, ensuring responsiveness. They incorporate a high-force, precise coil for exacting control in high-cycle applications.

Key Advantages of Hydraulic Cartridge Valves in Mobile Machinery

Hydraulic Cartridge Valve technology offers numerous benefits for modern mobile machinery. These advantages contribute significantly to the overall efficiency, performance, and operational lifespan of equipment.

Compactness and Space Efficiency

Cartridge valves provide exceptional compactness and space efficiency. Multi-function cartridge valves reduce the number of individual valves required in a manifold. This design significantly decreases the overall space claim. It also lessens the need for larger components, contributing to a reduced hydraulic footprint. Combining several functions into a single manifold using cartridge valves may occupy only 10% to 20% as much volume as conventional line-mounted systems. The high power density of these valves allows equipment manufacturers to downsize hydraulic systems. This downsizing occurs without sacrificing efficiency or power, leading to substantial space and weight savings.

Versatility and Modularity

Cartridge valves offer high versatility and modularity. Modular designs for these valves represent a growing trend in the industry. This design enables easy replacement and customization. This adaptability helps meet specific machinery requirements. It also enhances operational flexibility for various applications.

Enhanced Performance and Efficiency

These valves significantly improve performance metrics in mobile machinery. They offer rapid response times, often less than 0.05 seconds. Accuracy reaches ±0.5% across the full range of operation. They also provide precise turbine flow accuracy, ensuring consistent and reliable fluid control.

Reliability and Durability

Cartridge valves demonstrate high reliability and durability, even in demanding environments. For example, stainless steel cartridge valves used in offshore hydraulic tools can last 6–10 years. A 700-bar hydraulic valve typically operates for 5 to 10 years under normal conditions. Harsh environments, such as those with exposure to moisture, dust, salt spray, or abrasive particles, can reduce this lifespan to 3–5 years. However, predictive maintenance and condition monitoring allow some high-end valves in controlled environments to operate reliably for over 15 years.

| Application Type | Recommended Valve Type | Lifespan Expectancy |

|---|---|---|

| Offshore Hydraulic Tools | Stainless Steel Cartridge Valves | 6–10 years |

Simplified Maintenance and Serviceability

Cartridge valves simplify maintenance procedures for mobile machinery. Their modular construction allows for easy customization, scalability, and quick replacement or repair. This minimizes downtime and reduces maintenance costs. Opting for cartridge valves with standardized dimensions and accessible replacement parts streamlines repairs. Hydraulic pilot control valves simplify technician tasks. Their design allows easy access for inspection and repair. This enables quick identification and resolution of issues, thus minimizing maintenance time and ensuring operational continuity. The entire manifold assembly does not need removal to troubleshoot or replace valves. Hydraulic hoses and other valves remain intact during maintenance. This reduces downtime and streamlines the process. Reliable performance and quick maintenance prevent unexpected failures. This promotes scheduled maintenance over emergency repairs, maximizing productivity.

How Hydraulic Cartridge Valves Enable Modern Capabilities

Facilitating Complex Motion and Multi-Functionality

Hydraulic cartridge valves empower mobile machinery to perform intricate movements and execute multiple functions simultaneously. They achieve this by integrating various control elements into compact units. For instance, manufacturers design directional valves with isolated load-sense checks. Solenoid valves often feature internal flow checks or integrated pressure relief mechanisms. Proportional flow controls include integrated pressure compensation. Logic elements come equipped with built-in relief functions or flow regulation capabilities. Flow controls also offer adjustable pressure relief. These combinations allow for highly sophisticated hydraulic circuits.

Mobile machinery hydraulic circuits can become very complex. They utilize numerous valves for each function. Manifolds combine a pilot-operated valve with dual counterbalance valves, dual flow controls, and dual post-compensation and load sensing checks. This demonstrates the extensive multi-functionality achievable through cartridge valve combinations. Cartridge valves control direction, pressure, and flow within a single device. This contributes to compact installation and multi-functionality in mobile machinery.

Supporting Advanced Control Systems

Hydraulic cartridge valves seamlessly integrate with Electronic Control Units (ECUs), enabling advanced machine operation. HUSCO’s electro-hydraulic cartridge valves are specifically engineered for off-highway vehicles. They focus on high fidelity and consistent, high-precision performance. This design commitment allows OEMs to achieve higher machine-level control. It enables precise actuation of spools on main control valves, transmission controls, and various low-flow function applications.

Modern excavators utilize proportional valves controlled by ECUs to implement advanced features. These features include load-sensing hydraulics, travel speed limiting, and automated boom-lift compensation. These systems collectively enhance precision, improve fuel efficiency, and increase safety in machine operation. The integration of hydraulic cartridge valves with ECUs enables precise and remote operation of hydraulic systems. This integration significantly enhances automation capabilities and reduces the need for manual intervention. It aligns with current Industry 4.0 trends.

Contributing to Operator Comfort and Safety

The precision control offered by hydraulic cartridge valves directly enhances operator comfort and safety. Smooth and predictable hydraulic responses reduce sudden jolts and vibrations, creating a more comfortable operating environment. Operators experience less fatigue during long shifts. The reliability and durability of these valves minimize unexpected system failures, which could otherwise lead to dangerous situations. By integrating with advanced control systems, cartridge valves facilitate automated functions. These functions reduce the operator’s workload and potential for human error. This contributes to a safer working environment. For example, precise load handling prevents accidental drops or uncontrolled movements, protecting both the operator and surrounding personnel.

Optimizing Fuel Efficiency and Environmental Impact

Hydraulic cartridge valves play a crucial role in optimizing fuel efficiency and reducing the environmental impact of mobile machinery. Smart Load-Sensing Mobile Hydraulic Valves with Predictive Flow Control use sensors and algorithms. They anticipate future flow needs, minimizing energy waste. This allows machines to operate more efficiently and respond precisely to operator commands. Energy-Recovery Mobile Hydraulic Valves (ERV) for Hybrid Systems capture and reuse energy. This energy is typically lost during machine operation. ERVs significantly boost fuel efficiency, especially in hybrid systems.

Additive Manufactured (3D Printed) Mobile Hydraulic Valves for Optimized Flow Paths enable complex internal geometries. These geometries optimize fluid flow, reduce pressure drops, and improve efficiency. This leads to superior performance. Environmentally Friendly Mobile Hydraulic Valves with Biodegradable Fluid Compatibility are designed for use with biodegradable hydraulic fluids. They minimize environmental impact and support sustainable operations. They also help companies meet eco-friendly regulations. The integration of automation trends with regulatory compliance initiatives, particularly those focused on reducing environmental impact, presents significant opportunities for hydraulic cartridge logic valves. There is an enhanced focus on eco-friendly hydraulic fluids and energy-efficient valve architectures. This aligns with evolving standards set by environmental agencies. The adoption of advanced robotics and AI-driven automation, with hydraulic cartridge logic valves at their core, revolutionizes hydraulic control systems. These systems enable self-optimization, real-time diagnostics, predictive maintenance, and dynamic flow adjustments. All these features contribute to improved operational efficiency and a reduced environmental footprint. Stringent safety and environmental regulations, emphasizing emissions reduction and energy efficiency, compel manufacturers to adopt eco-conscious hydraulic solutions.

Hydraulic cartridge valves deliver essential precision, efficiency, and compactness for advanced mobile equipment. Their integrated design and versatile functionality are fundamental to mobile hydraulics’ performance, reliability, and operational sophistication. These components quietly power progress. They are the indispensable backbone of modern mobile machinery.

FAQ

What is a hydraulic cartridge valve?

Hydraulic cartridge valves are compact, self-contained components. They control the flow, pressure, and direction of hydraulic fluid within a system. Engineers design them for integration into manifold blocks.

Why do people call hydraulic cartridge valves “invisible”?

People call them “invisible” because of their integrated design. Manufacturers seamlessly incorporate them into manifold blocks. This design reduces external plumbing and overall system size, making them less noticeable.

What are the main advantages of these valves in mobile machinery?

Hydraulic cartridge valves offer significant advantages. They provide compactness, versatility, enhanced performance, and high reliability. They also simplify maintenance, contributing to efficient and durable mobile machinery operation.

Post time: Dec-25-2025