Operators frequently observe hydraulic systems running at elevated temperatures. Excessive heat degrades system performance and accelerates component wear. This thermal stress significantly contributes to system failures. Beyond common issues, hidden causes of excessive heat often remain undetected, such as an improperly operating Balance Valve.

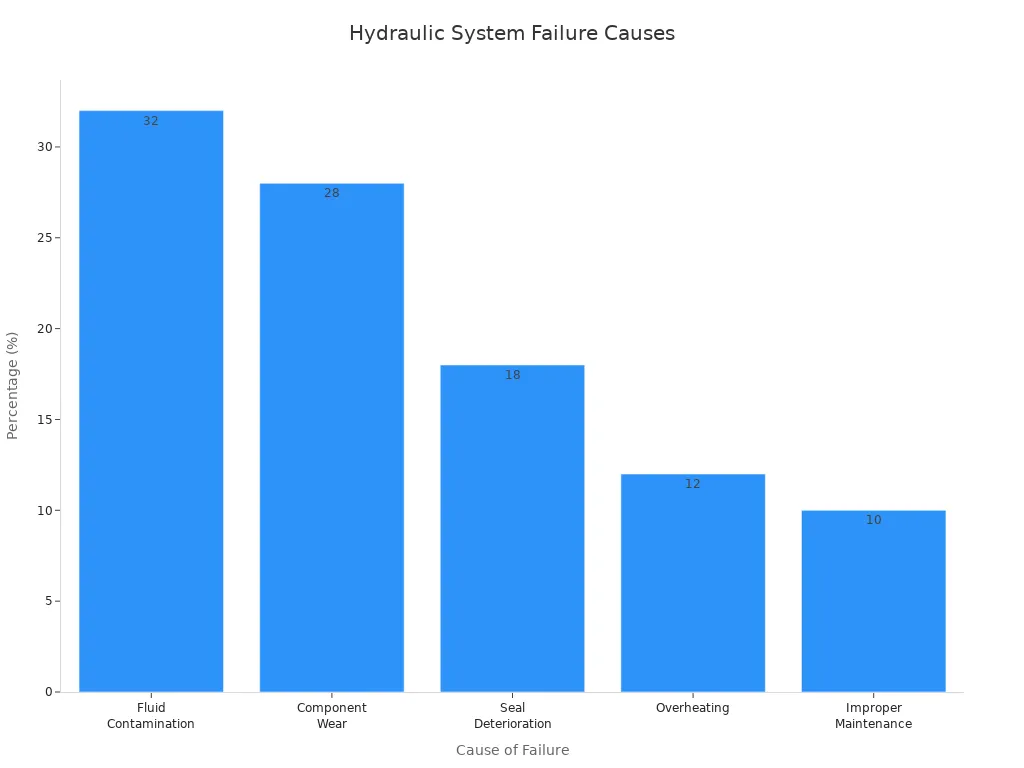

| Cause of Failure | Percentage of Breakdowns |

|---|---|

| Fluid Contamination | 32% |

| Component Wear | 28% |

| Seal Deterioration | 18% |

| Overheating | 12% |

| Improper Maintenance | 10% |

Key Takeaways

- Many things can make a hydraulic system too hot, like low fluid, wrong fluid thickness, or bad parts. These problems can damage the system.

- Balance valves help control fluid flow and pressure. If a balance valve is not set right, it can cause the system to get too hot.

- To keep your hydraulic system cool, pick the right balance valve, check it often, and fix any problems quickly. This helps the system work better and last longer.

Common Causes of Hydraulic System Overheating

Inadequate Fluid Levels and Contamination

Insufficient hydraulic fluid levels directly contribute to overheating. When fluid levels are low, systems experience a loss of pressure and increased heat generation. Operators may notice unusual sounds like whining or gurgling from the pump. Low fluid levels also lead to aeration, which accelerates fluid degradation and damages components. Air entering the pump intake due to a vortex further exacerbates these issues. Furthermore, particulate contamination in the fluid also generates heat. Installing depth filters to control particle contamination creates a pressure drop, which increases the heat load on the system.

Incorrect Fluid Viscosity

Fluid viscosity plays a critical role in heat management. When viscosity is too low, the fluid flows too freely. This leads to inadequate lubrication and increased component wear. Conversely, when viscosity is too high, the fluid struggles to move through the system. This results in excess heat generation and wasted energy.

| Viscosity Condition | Consequences |

|---|---|

| Too High | Increased friction, higher pressure drop, greater power consumption, increased heat generation, sluggish operation of valves and servos. |

| Too Low | Increased internal leakage (especially at higher temperatures), insufficient oil film leading to excessive wear or seizure of parts, decreased pump efficiency, sluggish operation. |

The majority of hydraulic equipment performs well with an operating viscosity range of 13 to 860 cSt. This range helps identify viscosity requirements based on startup and operating temperatures. For example, an ISO 68 fluid often provides better volumetric and overall pump efficiency in systems with low temperature startups and higher operating temperatures.

Undersized Components and Poor System Design

Undersized components and poor system design are significant contributors to overheating. Restricted fluid flow, often due to clogged filters, undersized hoses, or damaged pumps, causes rapid heat buildup. Excessive pressure drops from worn-out valves or sharp bends in piping convert hydraulic energy into heat. A pump or motor operating continuously near its maximum capacity generates more heat than a properly sized one. To minimize heat generation, designers must optimize fluid flow by correctly sizing components and avoiding sharp bends. They also control pressure and flow through proper pump and motor selection.

External Heat Sources and Insufficient Cooling

External factors also impact hydraulic system temperature. High ambient temperatures, poor airflow in enclosed spaces, or proximity to other heat-generating machinery can significantly raise system temperatures. Intense heat sources in the immediate vicinity of the hydraulic system also contribute to overheating. Effective cooling solutions are essential to counteract these external influences. Air-cooled oil coolers use fans and ambient air to dissipate heat. Water-cooled oil coolers use water for heat removal, offering high efficiency for continuous heavy-duty cooling.

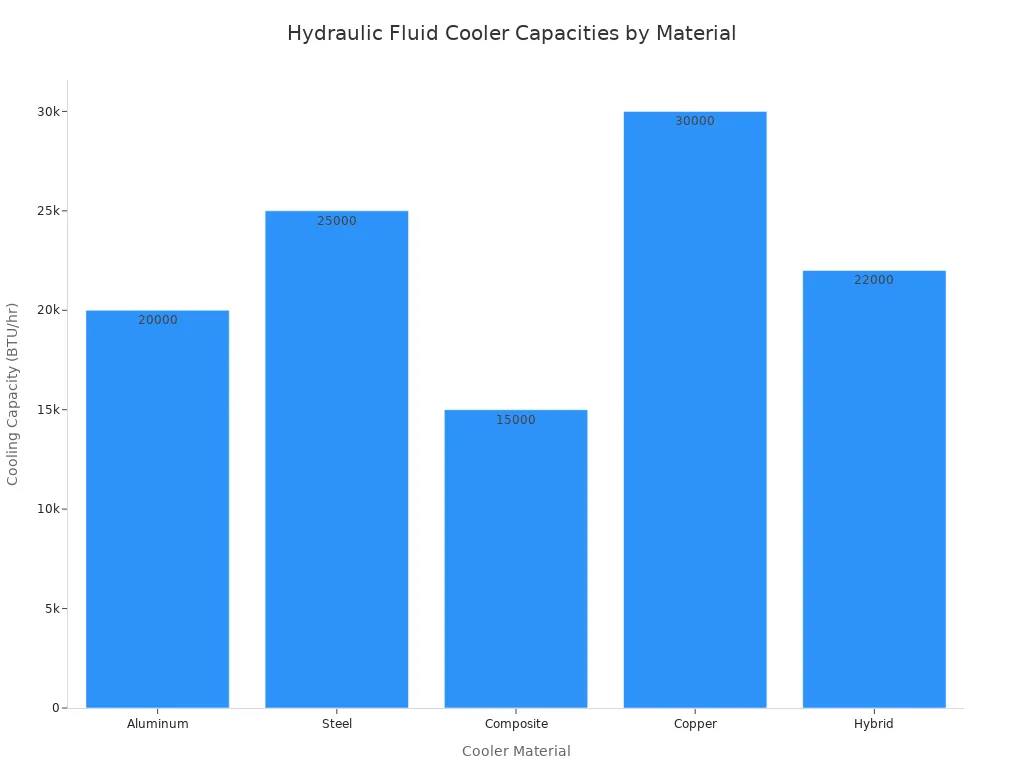

| Cooler Material | Cooling Capacity (BTU/hr) |

|---|---|

| Aluminum | 20,000 |

| Steel | 25,000 |

| Composite | 15,000 |

| Copper | 30,000 |

| Hybrid | 22,000 |

These coolers ensure equipment longevity and efficiency by maintaining optimal operating temperatures.

The Overlooked Role of Balance Valves in Heat Generation

Hydraulic systems often generate heat from various sources. However, the role of the Balance Valve in this process frequently goes unnoticed. Understanding its function and impact is crucial for effective thermal management.

What is a Balance Valve and How it Works

A Balance Valve plays a critical role in regulating fluid flow and pressure within a hydraulic system. Its fundamental operating principle involves an internal piston. This piston adjusts based on hydraulic system pressure. This adjustment balances the system. If the pressure exceeds a pre-set maximum, the hydraulic fluid overflows. This maintains safe operation. The valve’s operation also roots itself in the law of wave motion. Liquid flow creates fluctuating high and low pressure areas within the pipeline. To manage these fluctuations, the valve incorporates an adjustable air chamber and a spring. When high pressure occurs, the air chamber compresses. This relaxes the spring and adjusts the valve core to reduce flow. Conversely, during low pressure, the air chamber expands. This tightens the spring and adjusts the valve core to increase flow. This ensures system stability.

Counterbalance valves represent a specific type of Balance Valve. They allow fluid to flow freely into an actuator via a check valve. A relief valve prevents reverse flow until a pre-set pressure is reached. System pressure and load capacity determine this pre-set pressure. This pressure is higher than the system pressure under load. It then permits fluid to flow in the opposite direction. This enables the actuator to function. When pressure drops below this set value, the valve closes. This holds the load in place. The valve also adjusts to match cylinder speed with pump flow. This occurs if the load begins to accelerate uncontrollably.

How Imbalance Leads to Heat Generation

An unbalanced flow in a hydraulic circuit directly translates into wasted energy and heat. Poorly structured circuits can lead to excessive pump energy use. In district heating systems, hydraulic and thermal imbalances during operation lead to uneven heating. This affects user comfort. It also significantly increases energy consumption and heat loss.

Several factors contribute to this heat generation:

- Frictional Losses: Fluid movement through hoses, pipes, and components creates friction. This converts kinetic energy into heat. It also causes pressure drops. Longer flow paths and smaller diameters increase these losses.

- Turbulent Flow: Abrupt changes in direction, sharp bends, or sudden constrictions disrupt smooth flow. This leads to chaotic movement, wasted energy, and heat generation.

- Component Inefficiencies: Internal leakage in components like pumps and valves allows fluid to bypass its intended path. This results in lost energy.

- Heat Generation: Many forms of hydraulic energy loss ultimately manifest as heat. High temperatures degrade hydraulic fluid. This reduces its lubricity and viscosity. It also accelerates wear on seals and other components. This creates a cycle of inefficiency.

Specific hydraulic system components generate excessive heat due to flow imbalance. Flow controls, proportional, reducing, relief, reducing/relieving, and counterbalance valves, as well as servo valves, generate heat. They do this due to pressure drops when performing their functions. Incorrect sizing of fluid conductors also leads to excessive flow velocities. This causes heat generation. For instance, doubling the flow rate in a ½ inch OD pipe from 10 GPM to 20 GPM increases heat generation eightfold. Slippage in pumps, particularly as they wear, leads to internal leakage. High-pressure fluid bypasses the mechanical work. This converts pressure energy into heat. Internal leakage in valves, as they wear, creates paths for high-pressure oil to leak to low-pressure ports. This also generates heat.

Static vs. Dynamic Balancing for Heat Dissipation

Hydraulic systems employ two primary methods for balancing: static and dynamic. Static balancing involves setting fixed flow rates for different parts of the system. Technicians typically perform this during installation. It ensures a predetermined distribution of fluid. However, static balancing does not adapt to changing system conditions or loads. This can lead to inefficiencies and heat generation when demand fluctuates.

Dynamic balancing, conversely, uses automatic control valves. These valves continuously adjust flow rates in response to real-time system demands. This adaptive approach maintains optimal flow distribution under varying operating conditions. Dynamic balancing minimizes pressure drops and turbulent flow. This significantly reduces heat generation. It also improves overall system efficiency. While static balancing offers a simpler, lower-cost solution, dynamic balancing provides superior heat dissipation and energy savings in complex or variable load systems.

Improperly Adjusted Balance Valve Settings

An improperly adjusted Balance Valve can have severe consequences for system pressure and flow. This directly contributes to overheating. Incorrect adjustment of a hydraulic flow control valve is a common cause of erratic fluid delivery. Without proper flow control, machinery can operate unpredictably. This reduces efficiency and potentially causes part deterioration.

Pressure fluctuation or instability often results from a valve’s regulating device failing. This could be due to fatigued springs or an obstructed valve core. Such issues prevent the valve from maintaining a stable pressure. This leads to fluctuations. An inaccurate pressure setting can also occur. A loose adjustment bolt or fatigued spring in the valve’s adjustment mechanism causes the actual system pressure to deviate from the desired set value.

An improperly set Balance Valve leads to flow rates that are either too high or too low. This incorrect flow rate can result in inconsistent temperature distribution across different areas of a system. This directly contributes to localized overheating and overall thermal inefficiency. Regular inspection and precise adjustment of these valves are essential for maintaining optimal system performance and preventing excessive heat buildup.

Practical Solutions for Optimal Heat Dissipation

Proper Balance Valve Selection and Sizing

Selecting the correct Balance Valve and ensuring its proper size is fundamental for effective heat dissipation. Engineers must understand true process conditions. This includes minimum and maximum flow, upstream and downstream pressures, and differential pressure. They also consider fluid properties. Determining the required Cv at minimum and maximum flows is a crucial step in initial sizing. Proper valve sizing balances efficiency and cost. Larger valves reduce pressure losses. This minimizes power waste and excessive heat generation. Conversely, smaller valves lead to higher pressure drops. These pressure drops waste power and create heat. This might necessitate a heat exchanger. Any pressure differential in a hydraulic system not performing work directly correlates to heat loss and wasted horsepower.

Routine Inspection and Adjustment of Balance Valves

Regular inspection and precise adjustment of Balance Valves are essential for maintaining optimal system performance. Technicians conduct monthly visual inspections to identify wear and tear. They look for fluid leaks, corrosion, or physical damage. They also schedule regular functionality tests during routine maintenance checks. These tests ensure correct operation under load conditions. They monitor response times and flow rates. Key indicators of a malfunctioning or improperly adjusted Balance Valve include sluggish actuator movement, unusual noises, and fluid leaks. System overheating, even under normal load conditions, also signals a problem.

System Audits for Optimal Flow Distribution

System audits are critical for identifying and correcting flow imbalances that contribute to overheating. Flow analysis is an advanced technique for troubleshooting hydraulic systems. It directly addresses the identification of flow imbalances. Thermal imaging also detects heat caused by bypassing oil. This indicates flow issues and internal leakage. Flow meters are essential for troubleshooting hydraulic problems and checking pump conditions. They measure flow in pressure, return, and case drain lines. A laser heat gun detects heat from bypassing oil. This indicates issues like relief valve bypass or pump slippage.

Integrating Advanced Monitoring for Early Detection

Advanced monitoring systems provide real-time data for early detection of potential overheating issues. Temperature sensors detect when equipment operates outside safe temperature ranges. Pressure sensors monitor pressure to detect performance degradation. IoT sensors monitor critical parameters like vibration, temperature, and pressure. The Heavy Duty Hydraulic System Flow Monitor is designed for real-time monitoring of hydraulic oil flow and temperature. This device is suitable for permanent installation. Predictive maintenance utilizes machine learning algorithms. These algorithms learn from historical data to identify patterns that precede equipment failures. Artificial intelligence processes vast amounts of sensor data in real-time. It identifies subtle changes indicative of developing problems.

Balance valves significantly impact hydraulic system heat dissipation. Proper selection and routine adjustment prevent overheating. Operators ensure cooler, more efficient systems through regular maintenance and system audits. Seek professional help for persistent overheating issues. Experts diagnose complex problems and implement advanced solutions.

FAQ

What is the main purpose of a balance valve in a hydraulic system?

A balance valve regulates fluid flow and pressure. It ensures balanced operation and prevents over-pressurization. This maintains system stability.

How does an improperly adjusted balance valve lead to overheating?

Incorrect settings cause flow imbalances and excessive pressure drops. These issues convert hydraulic energy into heat. This raises system temperature.

What is the difference between static and dynamic balancing for heat dissipation?

Static balancing uses fixed flow rates. Dynamic balancing automatically adjusts flow in real-time. Dynamic balancing offers superior heat dissipation and efficiency.

Post time: Dec-24-2025