Ningbo Airtac type 4M210 08 air control pneumatic solenoid valve

Details

Product name: Namur Solenoid valve

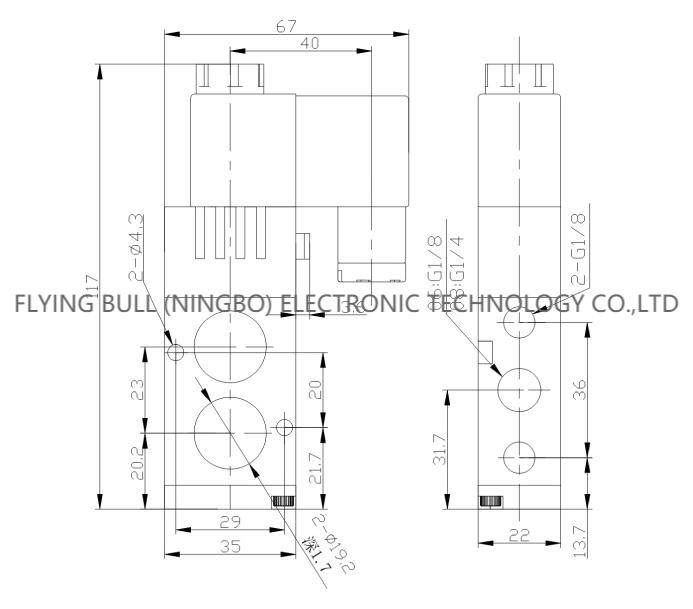

Port size: G1/4"

Working pressure: 0.15-0.8Mpa

Material: aluminum

Media: gas

Working medium: Air Water Oil Gas

Packing: One Piece Valve

Color: Silver black

Model: 4M210-08

After Warranty Service: Spare parts

Local ServiceLocation: None

Supply Ability

Selling Units: Single item

Single package size: 7X4X5 cm

Single gross weight: 0.300 kg

Product introduction

Common fault causes and treatment measures of electromagnetic reversing valve

1. The reversing of the solenoid valve is unreliable, and there are several common faults of the electromagnetic reversing valve that do not reverse. The main manifestations are: the reversing speed in the two directions is different or stays for a period of time during the reversing process, and it is found that it does not reset or reverse after being electrified again.

2. There are several factors that affect the reversing reliability of the electromagnetic reversing valve: one is the friction of the valve core; The second is the restoring force of the spring; The third is the attraction of electromagnet. The most basic performance of reversing valve is reversing reliability. In order to ensure the reliability of reversing, the valve core should be less than the friction resistance of spring force, so as to ensure the reliability of reset. The attraction of electromagnet should also be greater than the sum of spring force and friction resistance of valve core, in order to ensure reliable commutation. Therefore, by analyzing these factors, we can find out the reasons of unreliable commutation and get the solutions.

3. The assembly quality and machining quality of the electromagnetic reversing valve are not good, which leads to poor reversing, for example, the burr in the valve core is not removed at all or is not cleaned thoroughly enough. In particular, once the burr inside the valve body is transferred, it will be difficult to remove it, which poses a great potential threat. However, due to the progress of technology, there have been new means to remove it, and the effect is good.

4. No commutation due to the quality problem of electromagnet. For example, the quality of the electromagnet is poor, which leads to the movable core of the AC electromagnet being stuck by the guide plate, and if it is dirty or rusted, it will also lead to sticking. These phenomena may cause the electromagnet to fail to attract well, the valve core cannot move or the movement is not enough, and the oil circuit does not switch, that is, it does not change direction. For another example, the electromagnet can't be energized because of the circuit fault or the falling of the incoming and outgoing wires. At this time, the multimeter can be used to check the reason and position of the non-energization and eliminate it.

Product picture

Company details

Company advantage

Transportation

FAQ