621957 Replacement Parts Kit for Burner Hole Assembly of Refrigerator

Details

-

Colour: Onecolor

Batteries Included?: No

Batteries Required?: No

Package dimensions :8.79 x 5.99 x 3 cm; 32 Grams

Brand:FLYING BULL

Points for attention

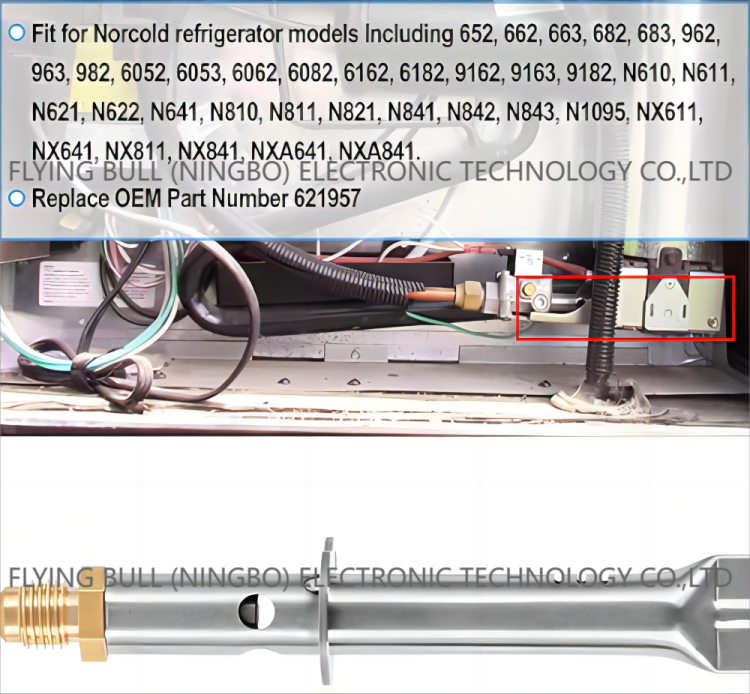

The 621957 refrigerator burner orifice replacement part is compatible with N6, N8, N1095, 600, 6000, 900, and 9000 models. Fit for Norcold RV refrigerator models Including 652, 662, 663, 682, 683, 962, 963, 982, 6052, 6053, 6062, 6082, 6162, 6182, 9162, 9163, 9182, N610, N611, N621, N622, N641, N810, N811, N821, N841, N842, N843, N1095, NX611, NX641, NX811, NX841, NXA641, NXA841.

1. Daily maintenance, maintenance

1) Always keep the surfaces clean.

2) When the equipment is stopped, the quick-opening blind plate (flange cover) should be lubricated in time according to the regulations. The lead screw in the opening and closing parts should be coated with lubricating grease. Other parts should also be coated with lubricating grease as far as possible. For the parts that cannot be coated with lubricating grease, 10# or 20# engine oil can be injected.

2. Maintenance during operation

1) It is suggested that the operator should be responsible for the usual maintenance of the equipment.

2) Always keep the surface of the equipment clean.

3) Monitor the reading of differential pressure meter at any time. When the differential pressure reaches 0.O2Mpa, flush the filter element.

3. Inspection cycle

1) The regular inspection of this equipment must be carried out in strict accordance with the relevant provisions in Chapter VI of the Capacity Gauge.

2) The equipment shall be comprehensively inspected at least once a year, the wall thickness of the equipment shall be measured, and the pressure-bearing weld of the equipment shall be nondestructive tested every two years. All inspection and test results shall be recorded in the technical file of the equipment.

3) When there is pressure inside the equipment, no maintenance is allowed. Maintenance under special circumstances must be carried out in strict compliance with the provisions of Article 122 of the "Capacity Regulation".

4. Maintenance during parking

1) When the equipment is parked, the liquid in the equipment should be drained.

2) Close all valves.

3) Clean the surface of the equipment thoroughly.

4) All rotating parts shall be coated with grease.

5) Cover all the devices with canvas to prevent dust and dirt from depositing on the equipment surface.

Product specification

Company details

Company advantage

Transportation

FAQ