Normally closed electromagnetic directional valve SV08-22

Details

Power:220VAC

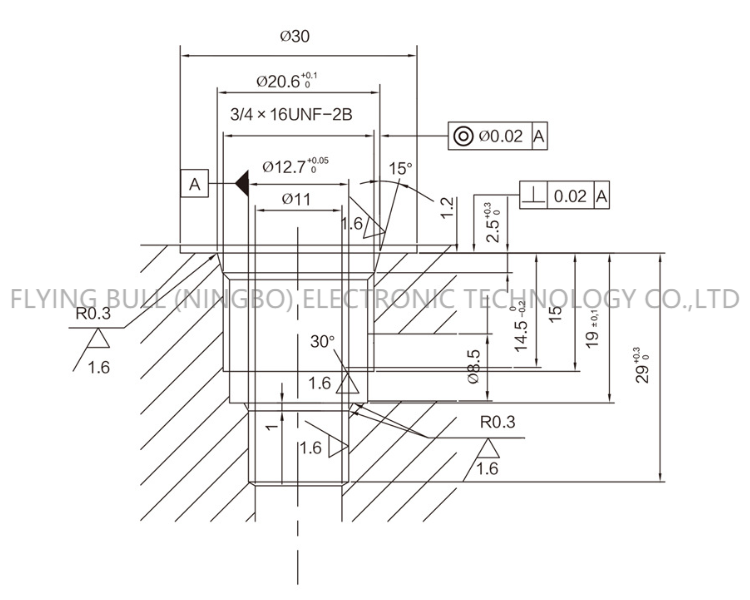

Dimension(L*W*H):standard

Valve type:Solenoid reversing valve

Maximum pressure:250bar

Maximum Flow Rate:30L/min

Temperature:-20~+80℃

Temperature environment:normal temperature

Applicable industries:machinery

Type of drive:electromagnetism

Applicable medium:petroleum products

Points for attention

The failure of the solenoid valve will directly affect the action of the switching valve and the regulating valve. The common failure is that the solenoid valve does not act, so it should be investigated from the following aspects:

1. If the connector of the solenoid valve is loose or the connector falls off, the solenoid valve may not be electrified, but the connector can be tightened.

2. If the solenoid valve coil is burnt out, remove the wiring of the solenoid valve and measure it with a multimeter. If the circuit is open, the solenoid valve coil is burnt out. The reason is that the coil is damp, which leads to poor insulation and magnetic leakage, resulting in excessive current in the coil and burning, so it is necessary to prevent rainwater from entering the solenoid valve. In addition, the spring is too hard, the reaction force is too large, the number of turns of the coil is too small, and the suction force is not enough, which can also cause the coil to burn. In case of emergency treatment, the manual button on the coil can be turned from the "0" position in normal operation to the "1" position to open the valve.

3. The solenoid valve is stuck: the fit clearance between the spool sleeve and the valve core of the solenoid valve is very small (less than 0.008mm), which is generally assembled in one piece. When there are mechanical impurities or too little lubricating oil, it is easy to get stuck. The treatment method can be used to stab the steel wire from the small hole in the head to make it bounce back. The fundamental solution is to remove the solenoid valve, take out the valve core and valve core sleeve, and clean it with CCI4 to make the valve core move flexibly in the valve sleeve. When disassembling, attention should be paid to the assembly sequence and external wiring position of each component, so as to reassemble and wire correctly. Also, check whether the oil spray hole of the oil mist sprayer is blocked and whether the lubricating oil is sufficient.

4. Air leakage: Air leakage will cause insufficient air pressure, making it difficult to open and close the forced valve. The reason is that the sealing gasket is damaged or the slide valve is worn, resulting in air leakage in several cavities. When dealing with the failure of the solenoid valve of the switching system, we should choose an appropriate opportunity to deal with it when the solenoid valve is out of power. If it cannot be handled within a switching gap, we can suspend the switching system and handle it calmly.

Product specification

Company details

Company advantage

Transportation

FAQ