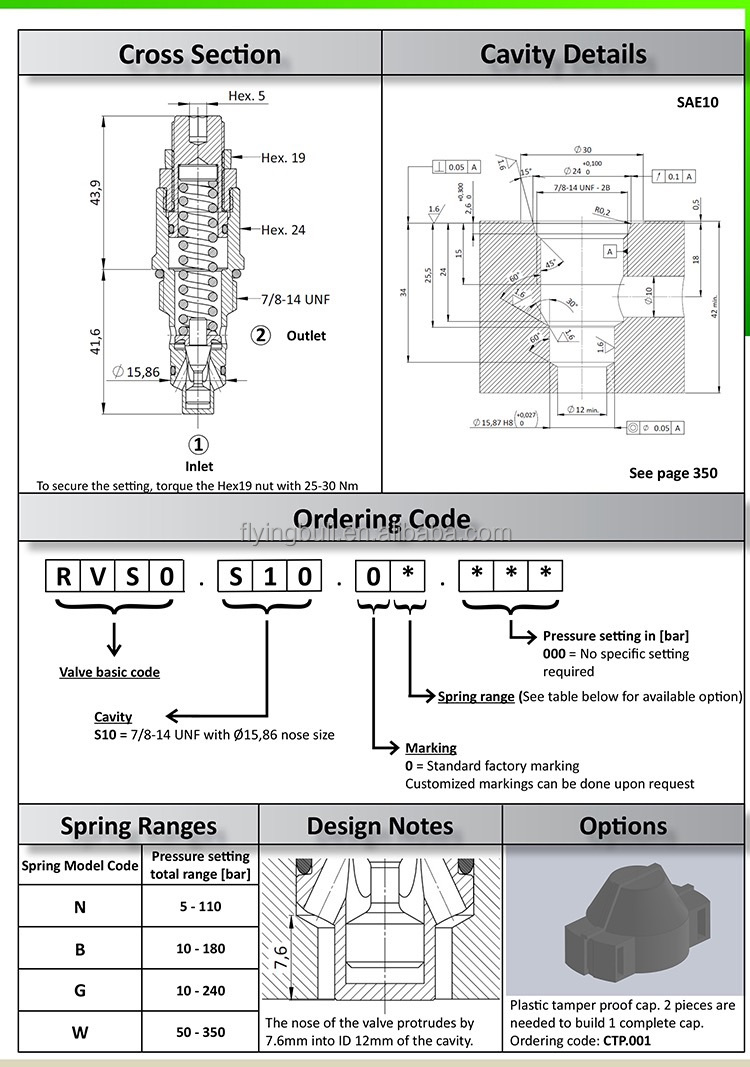

Overflow valve of S10 series threaded hydraulic system

Details

Product related information

Warranty:1 Year

Showroom Location:None

Brand Name:FLYING BULL

Place of Origin:Zhejiang, China

product information

Weight:1

Dimension(L*W*H):standard

Valve type:hydraulic valve

Product name:high pressure safety valve

Points for attention

Important note:

generally speaking, it is not worth the loss to choose valves with overlapping or dead zones and nonlinear valves for closed-loop control, so it must be avoided as far as possible when selecting the type. Recommended servo characteristic proportional valve, the following are several valves that have been successfully used with DELTARMC controller in the United States. Many valves provide +10V or 4-20mA input. Be sure to choose the valve with +10V control signal. Recommended servo characteristic proportional valve, the following are several valves that have been successfully used with DELTARMC controller in the United States. Many valves provide +10V or 4-20mA input. Be sure to select the valve with ±10V control signal.

The main reasons of pressure fluctuation caused by overflow valve are as follows:

1.The pressure fluctuation is caused by the loosening of locking nut due to vibration of the screw for adjusting pressure;

2. The hydraulic oil is unclean, and there is tiny dust, which makes the main spool slide inflexible, resulting in irregular pressure changes, and sometimes the valve will get stuck;

3. The damping hole is blocked and connected from time to time due to poor sliding of the main valve core;

4. The conical surface of the main valve core is not in good contact with the conical surface of the valve seat and has not been well run-in;

5. The damping hole of the main spool is too large to play a damping role;

6. The pilot valve straightening spring is bent, resulting in poor contact between the valve core and the cone seat and uneven wear.

Solutions to common faults in relief valve maintenance:

1. Clean the oil tank and pipeline regularly, and filter the hydraulic oil entering the oil tank and pipeline system;

2. If there is a filter in the pipeline, the secondary filter element should be added, or the filtering accuracy of the secondary element should be replaced; And remove and clean the valve components and replace them with clean hydraulic oil;

3. Repair or replace unqualified parts;

4.Appropriately reduce the damping aperture.

Product specification

Company details

Company advantage

Transportation

FAQ