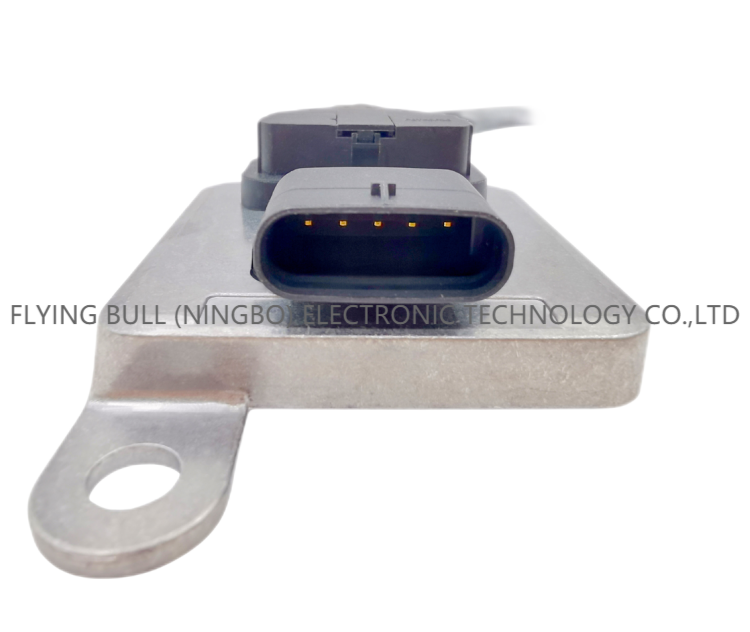

Nox Sensor A0009053606 for Benz W221 W205 251 166 207

Details

Marketing Type:Hot Product 2019

Place of Origin:Zhejiang, China

Brand Name:FLYING BULL

Warranty:1 Year

Type:pressure sensor

Quality:High-Quality

After-sales Service Provided:Online Support

Packing:Neutral Packing

Delivery time:5-15 Days

Product introduction

Why should we study the clutter signal on the waveform of oxygen sensor?

This is because the clutter may be caused by the low combustion efficiency. As long as the up-flow system is not in the correct working state, the catalyst cannot be accurately tested. The clutter of the oxygen sensor waveform can warn the decline of the performance of each engine cylinder. At this time, exhaust gas diagnosis is the most important. Because it can find that the conversion efficiency of the catalyst decreases and the performance of individual cylinders decreases. Clutter signals also hinder the normal operation of the controller of the fuel feedback control system (the feedback program in the engine control computer runs). "Fuel feedback control system controller" refers to the functional software program (called "feedback controller"), which is a program that receives the voltage signal of the oxygen sensor and calculates the correct immediate fuel injection or mixture control command. Generally, the feedback controller program is not designed to effectively eliminate the frequency of oxygen sensor signals generated due to abnormal system operation and fuel control commands. The chaotic high-frequency fluctuation signal can make the feedback controller lose control accuracy or "feedback rhythm". There are several effects here. First, when the operation accuracy of the feedback controller is affected, the fuel mixture ratio will exceed the catalyst window, which will affect the working efficiency of the converter and exhaust emissions. Secondly, the engine performance will also be affected. Clutter can be a decisive indicator that the out-of-control exhaust gas enters the catalyst. It is often found that when clutter exists, the exhaust gas entering the catalyst has no correct air-fuel ratio. It is very important to understand the clutter on the waveform of oxygen sensor for the repair and diagnosis of exhaust gas emission. In some cases, clutter is an obvious signal that the catalytic conversion efficiency is reduced, and then the exhaust emission exceeds the standard. In addition, the explanation of clutter on the waveform of oxygen sensor is a valuable tool for the diagnosis of engine performance or driving ability. Clutter is an indication of imbalance in combustion efficiency from one cylinder to another. The explanation and understanding of the clutter on the waveform of oxygen transmitter is also very important for the effective use of oxygen sensor signal repair and verification. Clutter on the waveform of the oxygen sensor indicates that the exhaust gas changes from one cylinder to another unbalanced, or more particularly, a higher oxygen content is not obtained from individual combustion processes. Most oxygen sensors can quickly feed back the voltage deviation produced by each combustion process when they work normally. The greater the signal limit of clutter, the greater the difference of oxygen composition measured from each combustion process. The clutter seen under different driving modes is not only important to determine the root cause of the failure of steady-state and transient exhaust gas tests, but also an effective judgment basis for drivability diagnosis. The oxygen sensor signal clutter that forms a one-to-one exhaust waveform with the peak burr of BC in the acceleration mode is a very important diagnostic signal, because it means that the ignition will fail under load. Generally, the larger the clutter amplitude. There are more oxygen sensors in the exhaust gas, so the clutter is an indication that the average oxygen content of the feedback gas entering the catalyst increases before the exhaust, and the nitrogen oxide in the catalyst cannot be reduced (chemically) in the rich oxygen environment (lean mixture). To sum up, it is known that the clutter signal on the waveform of oxygen sensor with completely normal feedback system has no obvious influence on exhaust gas or engine performance. A small amount of clutter can be ignored, while a large number of clutter is important. This just shows that diagnosis is an art. To learn to judge what is normal clutter and what is not requires practice, and the best teacher is experience. The best way to learn is to observe the waveform of oxygen sensor from observing different mileage and different types of cars. Understanding what is normal clutter and what is abnormal clutter is very valuable for effective exhaust emission repair and driving ability diagnosis, and it is worth taking time to learn. For most common systems, a software waveform is absolutely valuable. Having an oxygen sensor reference waveform for the system being controlled can determine what kind of clutter is allowable and normal, and what kind of clutter should be paid attention to. The criteria for good clutter are: if the engine performance is good, there should be no vacuum leakage, and the hydrocarbon (HC) compounds and oxygen content in the exhaust gas are normal. In this part of the experiment, as much information as possible will be given in order to understand that there is just enough time and space to cover all the topics about this in this training.

Product picture

Company details

Company advantage

Transportation

FAQ