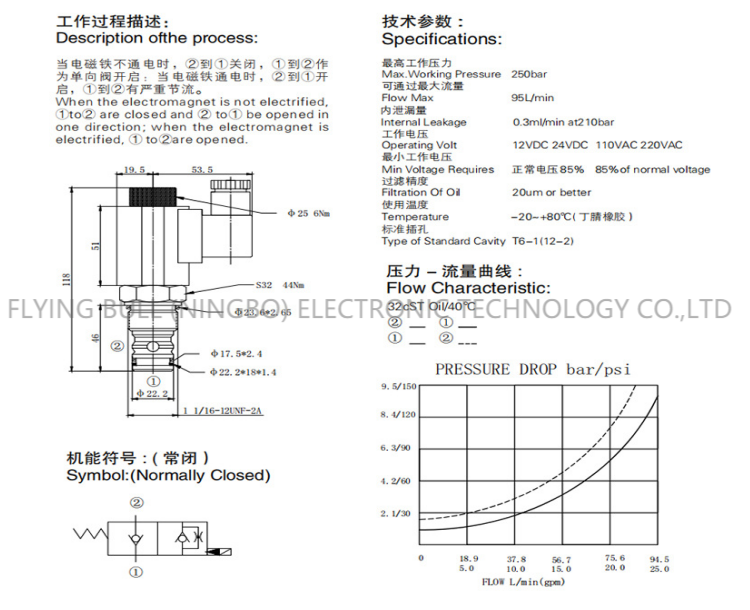

Hydraulic two-position two-way threaded cartridge valve SV12-20

Details

Lining material:alloy steel

Sealing material:hard metal

Temperature environmen:tone

Flow direction:one-way

Optional accessories:coil

Applicable industries:machinery

Type of drive:electromagnetism

Applicable medium:petroleum products

Product introduction

Functional description

Solenoid-driven, 2-way, normally closed, poppet-type, threaded hydraulic cartridge valve, designed for use as a load protection valve in applications requiring low internal leakage.

Operate

During power failure, SV12-20X acts as a check valve, allowing fluid to flow from port 1 to port 2, while preventing reverse flow. When energized, lift the flow path from port 2 to port 1 of the valve. In this mode, the flow from 1 to 2 is strictly limited.

Characteristic

Continuous load rated coil. Hardened valve seat, long service life and low leakage. Optional coil voltage and termination. Efficient wet armature structure. Ink cartridges are voltage interchangeable. Integral coil design. Manual override option. Optional waterproof electronic coil, protection level up to IP69K. A cost-effective cavity. N-ring with NBR.

There are many pipes used in the hydraulic transmission system. According to the different working pressure and assembly position, the one-way overflow valve is customized with seamless pipes, air-conditioning copper pipes, high-pressure hoses, nylon hoses and steel wire hoses.

In the whole process of hydraulic transmission system, we should always pay attention to the changes of geographical environment. If the pipes of solenoid valve manufacturers in Ningbo (especially steel wire hoses) are assembled unscientific, they are easily deformed due to environmental damage, resulting in oil leakage accidents. Therefore, the steel wire hose should have a volume of about 30% when it is assembled in a straight line, so as to integrate the environmental temperature change, the tensile strength and vibration of the steel wire hose; High-pressure hose should avoid continuous high temperature and corrosive gas. Once serious cracking, hardening or bagging is found, it needs to be dismantled immediately. If there are many steel wire hoses in the system, all aspects of spring hangers should be assembled and fixed separately or separated by rubber plates to avoid pipeline confusion.

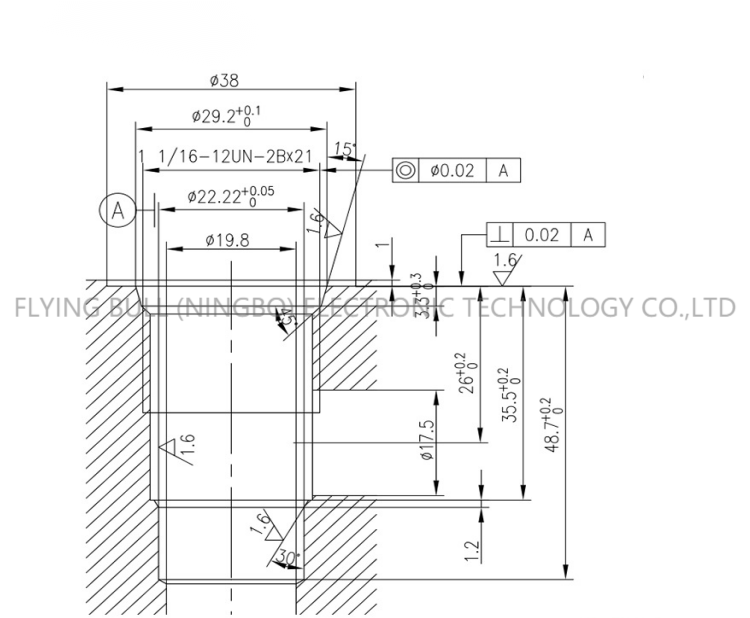

Product specification

Company details

Company advantage

Transportation

FAQ