300 series two-position five-way plate-connected solenoid valve

Details

Product name: Pneumatic Solenoid Valve

Acting type: Internally Pilot-actuated

Motion Pattern: Single-head

Working pressure: 0-1.0MPa

Operating Temperature: 0-60℃

Connection: G Threaded

Applicable Industries: Manufacturing Plant, Machinery Repair Shops, Energy & Mining

Supply Ability

Selling Units: Single item

Single package size: 7X4X5 cm

Single gross weight: 0.300 kg

Product introduction

Brief introduction

The two-position five-way solenoid valve is an automatic basic element used to control fluid, belonging to the actuator; It is not limited to hydraulic and pneumatic. Solenoid valves are used to control the direction of hydraulic flow. Mechanical devices in factories are generally controlled by hydraulic steel, so they will be used. Working principle of solenoid valve: There is a closed cavity in the solenoid valve, and there are through holes in different positions, each hole leads to different oil pipes. There is a valve in the middle of the cavity and two electromagnets on both sides. When the magnet coil on which side is energized, the valve body will be attracted to which side. By controlling the movement of the valve body, different oil discharge holes will be blocked or leaked, while the oil inlet hole is always open, the hydraulic oil will enter different oil discharge pipes, and then the oil pressure will push the oil-filled piston, which in turn will drive the piston rod. In this way, the mechanical movement is controlled by controlling the current of the electromagnet.

Classify

Looking at solenoid valves at home and abroad, so far, they can be divided into three categories: direct-acting, recoil and pilot, while recoil can be divided into diaphragm recoil solenoid valves and piston recoil solenoid valves according to the differences in disc structure and material and principle; Pilot type can be divided into: pilot diaphragm solenoid valve, pilot piston solenoid valve; From the valve seat and sealing material, it can be divided into soft sealing solenoid valve, rigid sealing solenoid valve and semi-rigid sealing solenoid valve.

Matters need attention

1. When installing the solenoid valve, it should be noted that the arrow on the valve body should be consistent with the flow direction of the medium. Do not install it where there is direct dripping or splashing water. Solenoid valve should be installed vertically upward.

2. The solenoid valve shall ensure that the power supply voltage works normally within the fluctuation range of 15%-10% of the rated voltage.

3. After the solenoid valve is installed, there shall be no reverse pressure difference in the pipeline. It needs to be electrified several times to make it warm before it can be put into use.

4, solenoid valve should be thoroughly cleaned before installation. The medium to be introduced should be free of impurities. Filter is installed in front of the valve.

5. When the solenoid valve fails or is cleaned, a bypass device should be installed to ensure the system to continue running.

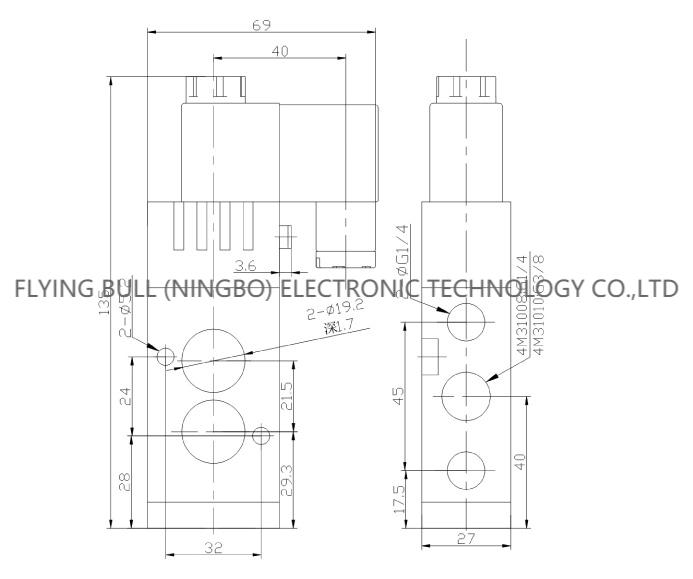

Product picture

Company details

Company advantage

Transportation

FAQ